Method for preparing flocculation aid for pretreating blue algae biogas slurry

A technology of coagulation aid and pretreatment, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of small flocs, difficult to settle, high solid content, and achieve the formation of large flocs, fast settling speed and waste residue moisture content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

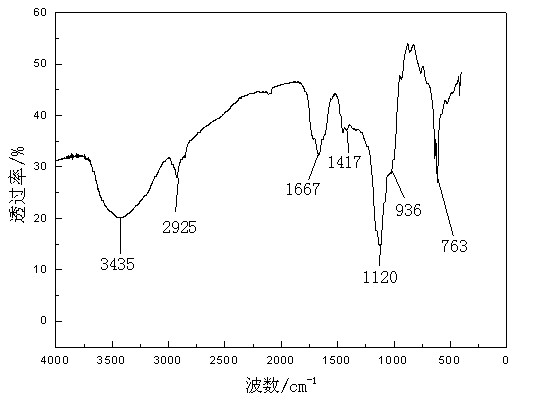

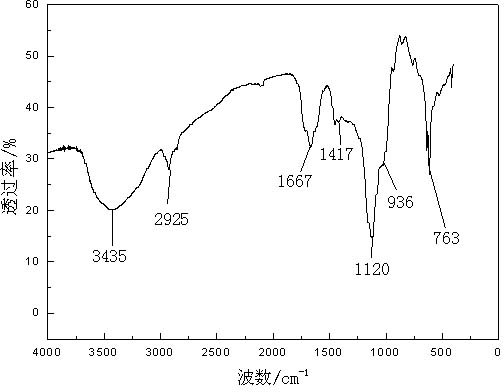

Image

Examples

Embodiment 1

[0022] The monomer AM, the reducing agent pentaerythritol, and the oxidizing agent ceric ammonium nitrate were prepared in advance into aqueous solutions with a mass concentration of 5%, and 30mL of the AM solution and the reducing agent containing 1.8×10 -4 mol aqueous solution, the reaction bottle was evacuated (filled with nitrogen) for 3 times, sealed after fully deoxidizing, and 1.8×10 -4 mol of aqueous solution, shake the reaction bottle to mix evenly, then place the reaction bottle in a constant temperature water bath at 47.5°C, and react for 16 hours to obtain SPAM colloid. Add 0.02 mol of NaClO and 0.04 mol of NaOH at 10°C to the SPAM solution at 10°C under stirring, and react at 35°C for 20 minutes under temperature control to obtain the Hofmann rearrangement product of SPAM.

[0023] According to the mass ratio of starch to AM of 1:1.5, put 1g of soluble starch into the reaction kettle, add 20mL of distilled water, and gelatinize in a constant temperature water bath...

Embodiment 2-5

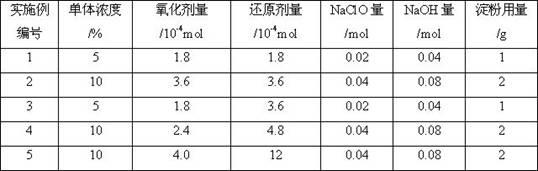

[0027] The difference between Examples 2-5 and Example 1 is that different monomer concentrations, oxidizing agent dosage, reducing agent dosage, NaClO dosage, NaOH dosage and starch dosage, other raw material dosage and operating conditions are used in the synthesis process of coagulant aid are the same. See Table 1 for the raw material ratios of Examples 1-5, and see Table 2 for the corresponding cyanobacterial biogas slurry treatment effects.

[0028] Table 1

[0029]

[0030] Table 2

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com