Gravity filling mortar

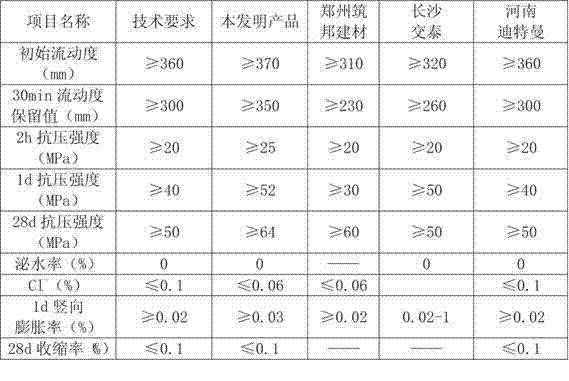

A mortar and gravity technology, applied in the field of concrete additives, can solve the problems of difficult to meet at the same time, unqualified mortar fluidity and early strength, and no obvious advantages, so as to achieve controllability, improve mortar strength, and prevent shrinkage cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

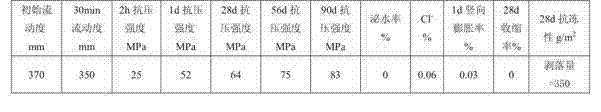

Examples

Embodiment 1

[0019] formula:

[0020] 400kg of sulfoaluminate cement with a strength grade of 42.5, 0.5kg of naphthalene-based superplasticizer (produced by Sichuan Hengze Building Materials Co., Ltd.), 0.1kg of citric acid, and 0.05 calcium formate kg, 0.01kg of starch, 0.1kg of fluorine-based defoamer, 599.24kg of aggregate (including 178.12kg of ceramsite with a particle size of 0.5-3mm, 182.12kg of 30-80 mesh quartz sand, and a fineness modulus of 0.65-1 River sand 239kg).

[0021] During construction, add water to the above product and stir to form a slurry (the weight ratio of water to dry powder mortar of this product is 0.16).

Embodiment 2

[0023] formula:

[0024] 500kg of sulfoaluminate cement with a strength grade of 42.5, 5kg of HZ-3 sulfamate superplasticizer (produced by Sichuan Hengze Building Materials Co., Ltd.), 0.5kg of citric acid, formic acid 0.25kg of calcium, 0.05kg of starch, 0.5kg of silicon defoamer (polydimethylsiloxane), 493.7kg of aggregate (including 146.35kg of ceramsite with a particle size of 0.5-3mm, 150.35kg of 30-80 mesh quartz sand kg, 197kg of river sand with a fineness modulus of 0.65-1).

[0025] During construction, add water to the above product and stir to form a slurry (the weight ratio of water to dry powder mortar of this product is 0.16).

Embodiment 3

[0027] formula:

[0028] 600kg of sulfoaluminate cement with a strength grade of 42.5, 10kg of polycarboxylate superplasticizer NT-201 (produced by Suzhou Fuke New Building Materials Co., Ltd.), 1kg of citric acid, 0.5kg of calcium formate, 0.1kg of starch, fluorine Antifoaming agent 1kg, aggregate 387.4kg (including 115kg of ceramsite with a particle size of 0.5-3mm, 117.4kg of quartz sand with a particle size of 30-80 mesh, and 155kg of river sand with a fineness modulus of 0.65-1).

[0029] During construction, add water to the above product and stir to form a slurry (the weight ratio of water to dry powder mortar of this product is 0.16).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com