Flexible three-dimensional force sensor and decoupling method and manufacturing method thereof

A manufacturing method and three-dimensional force technology, applied in the field of sensors, can solve the problems of high manufacturing cost and complicated manufacturing process of tactile sensors, and achieve the effect of improving sensitivity and precision and avoiding frequent breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

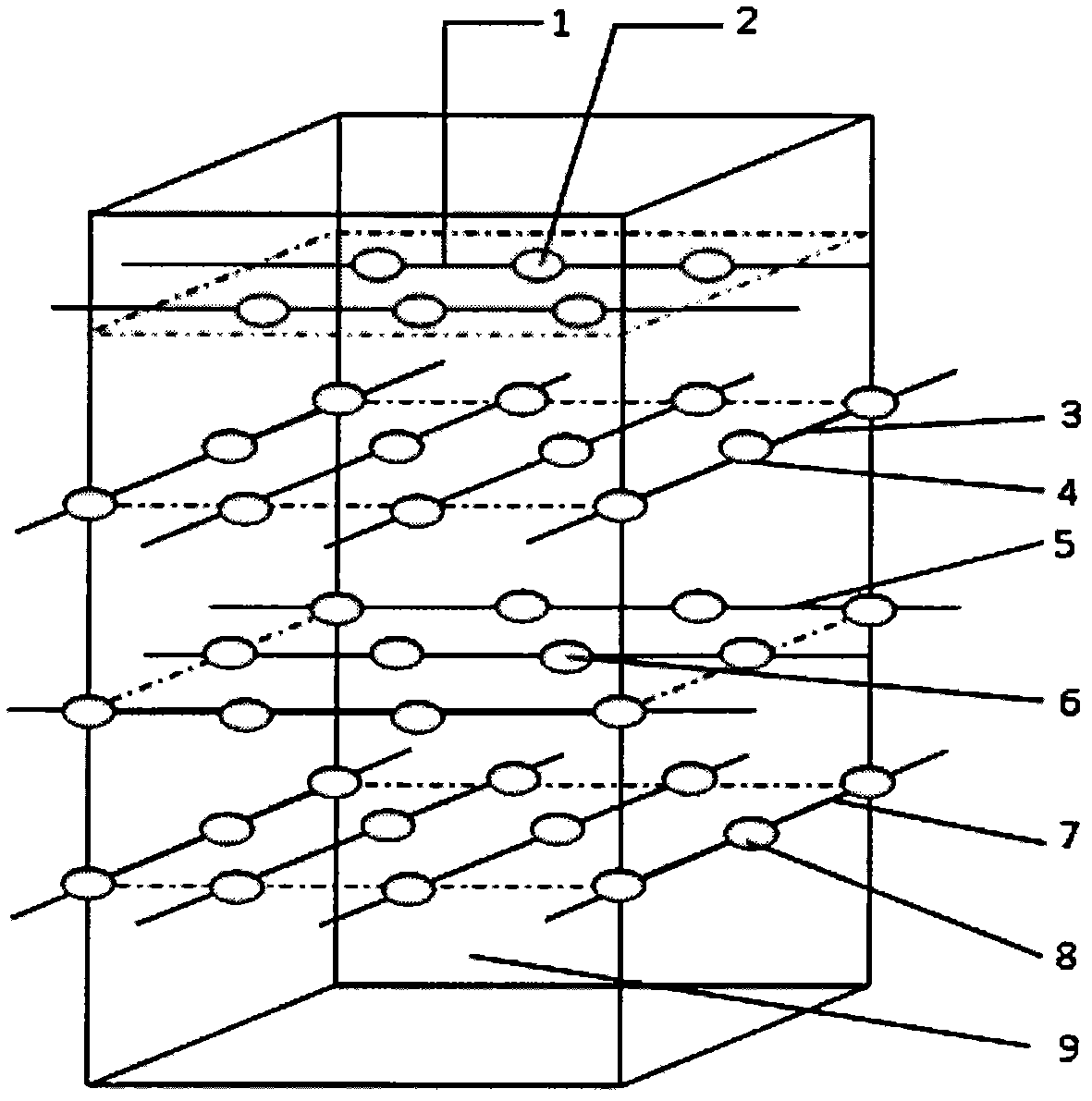

[0043] see figure 1 , the flexible three-dimensional force sensor consists of the first layer of wires 1, the second layer of wires 3, the third layer of wires 5 and the fourth layer of wires 7, which are parallel to each other and have the same spacing between the layers of wires, and the first layer of wires 1, the second layer of wires The layer wire 3, the third layer wire 5 and the fourth layer wire 7 are composed of a plurality of first layer electrodes 2, second layer electrodes 4, third layer electrodes 6 and fourth layer electrodes 8 connected at equal intervals respectively. Wherein, the first layer of wires 1 and the third layer of wires 5 are arranged in parallel, the second layer of wires 3 and the fourth layer of wires 7 are arranged in parallel, and the first layer of wires 1 and the second layer of wires 3 are arranged vertically, and the second layer of wires 3 It is vertically arranged with the third-layer wire 5 , and the third-layer wire 5 is vertically arr...

Embodiment 2

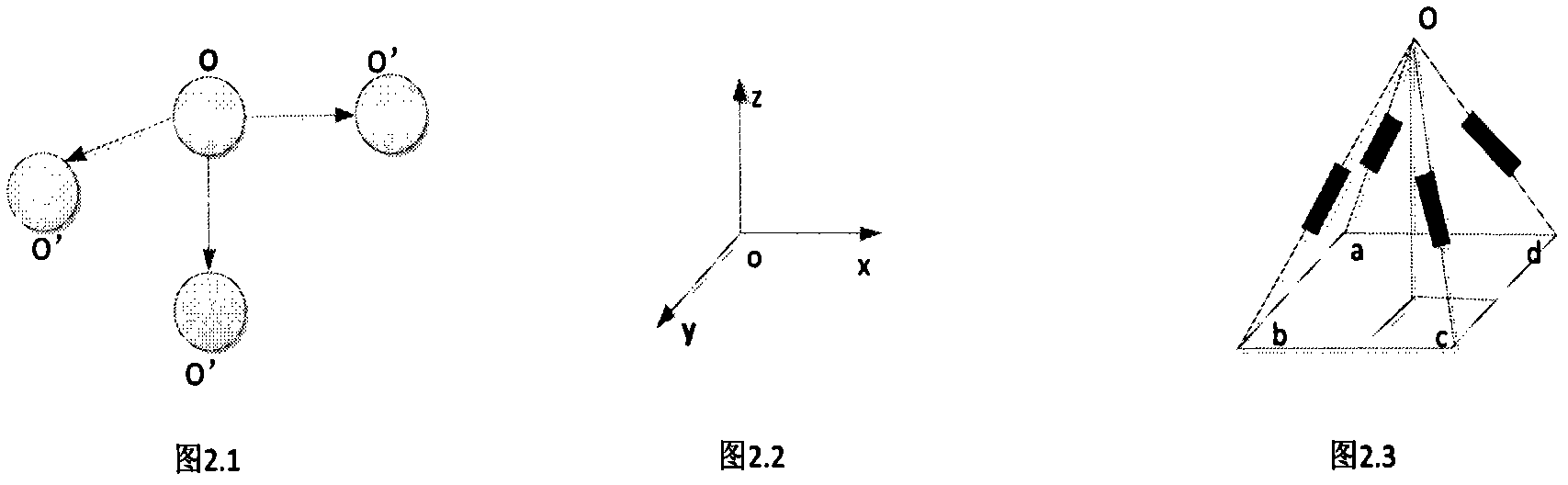

[0045]When the force is applied to the flexible three-dimensional force sensor, the force comes from three different directions, that is, the forces in the X direction, the Y direction and the Z direction are combined, and finally the first layer of electrodes 2 and the second layer of electrodes 4, the first layer of electrodes The conductive rubber between the third-layer electrodes 6 and the fourth-layer electrodes 8 is squeezed, and the displacement changes, thereby changing the resistance value. The resistance value before and after the change is obtained by row and column scanning, combined with the state equation of the conductive rubber F=f(Δi), Δi is the displacement in the X, Y, and Z directions, and the f function in the formula is determined by the properties of the conductive rubber.

[0046] see figure 2 The first-layer electrodes 2 and their corresponding four second-layer electrodes 4, four third-layer electrodes 6, and four fourth-layer electrodes 8 constitut...

Embodiment 3

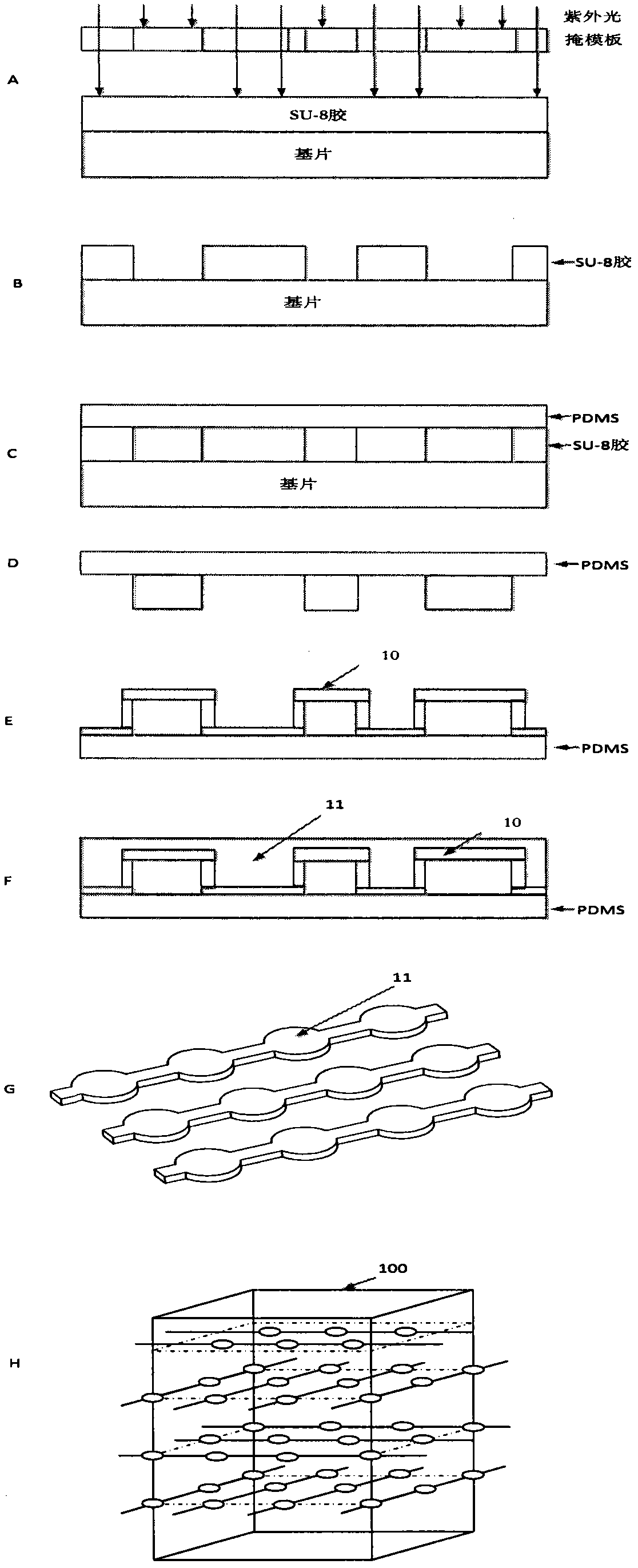

[0052] see image 3 , the manufacturing method of the flexible three-dimensional force sensor is:

[0053] Among them, steps 1 to 10 are the method of mass-producing microelectrodes and wires by using the SU-8+PDMS-based UV-LIGA process, and steps 11 to 12 are the assembly and curing of the sensor.

[0054] Step 1 Pretreatment of the substrate

[0055] Silicon wafers are used as substrates and cleaned. It is mainly washed with isopropyl or methanol. If there is oil stain, it needs to be cleaned with methylene dichloride to completely remove it, and then the substrate is dried.

[0056] Step 2 throw glue

[0057] Combining the parameters of SU-8 provided by IBM, select SU-850 photoresist, rotate at a speed of 250r / min for 10 seconds, and then rotate at a speed of 1200r / min for 30 seconds to complete the coating with a thickness of 100 microns.

[0058] Step 3 pre-bake

[0059] In order to reduce the generation of thermal stress in the SU-8 glue and the resulting influence,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com