Metal grating coupling SPR (Surface Plasmon Resonance) detection chip and manufacturing method thereof

A metal grating and detection chip technology, which is applied in the measurement of color/spectral characteristics, etc., can solve the problems of time-consuming, expensive projection exposure machines, unfavorable exposure of large-area graphics, etc., to reduce process time and cost, and to benefit The effect of industrial mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

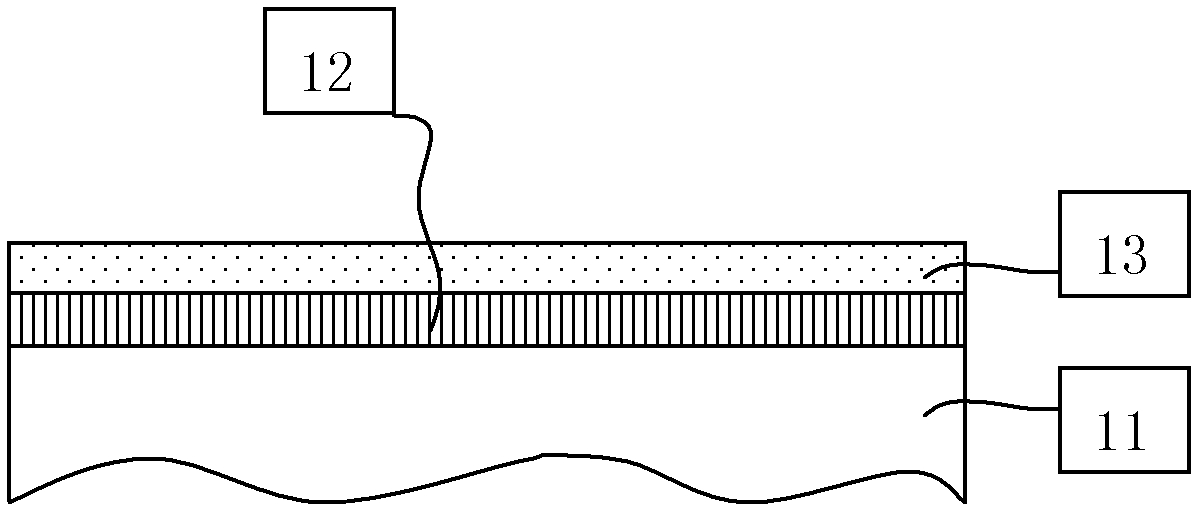

[0031] Example 1 refer to figure 1 , the metal grating coupling SPR detection chip includes: a transparent substrate 11, a metal grating coupling layer 12 and a microfluidic layer 13, the microfluidic layer is distributed with microfluidic channels bonded with the metal grating coupling layer; the microfluidic channel is bonded to the metal grating coupling layer; The grating coupling layer is cross-contacted.

[0032] The aforementioned transparent substrate is composed of a transparent organic material or a transparent inorganic material, preferably glass.

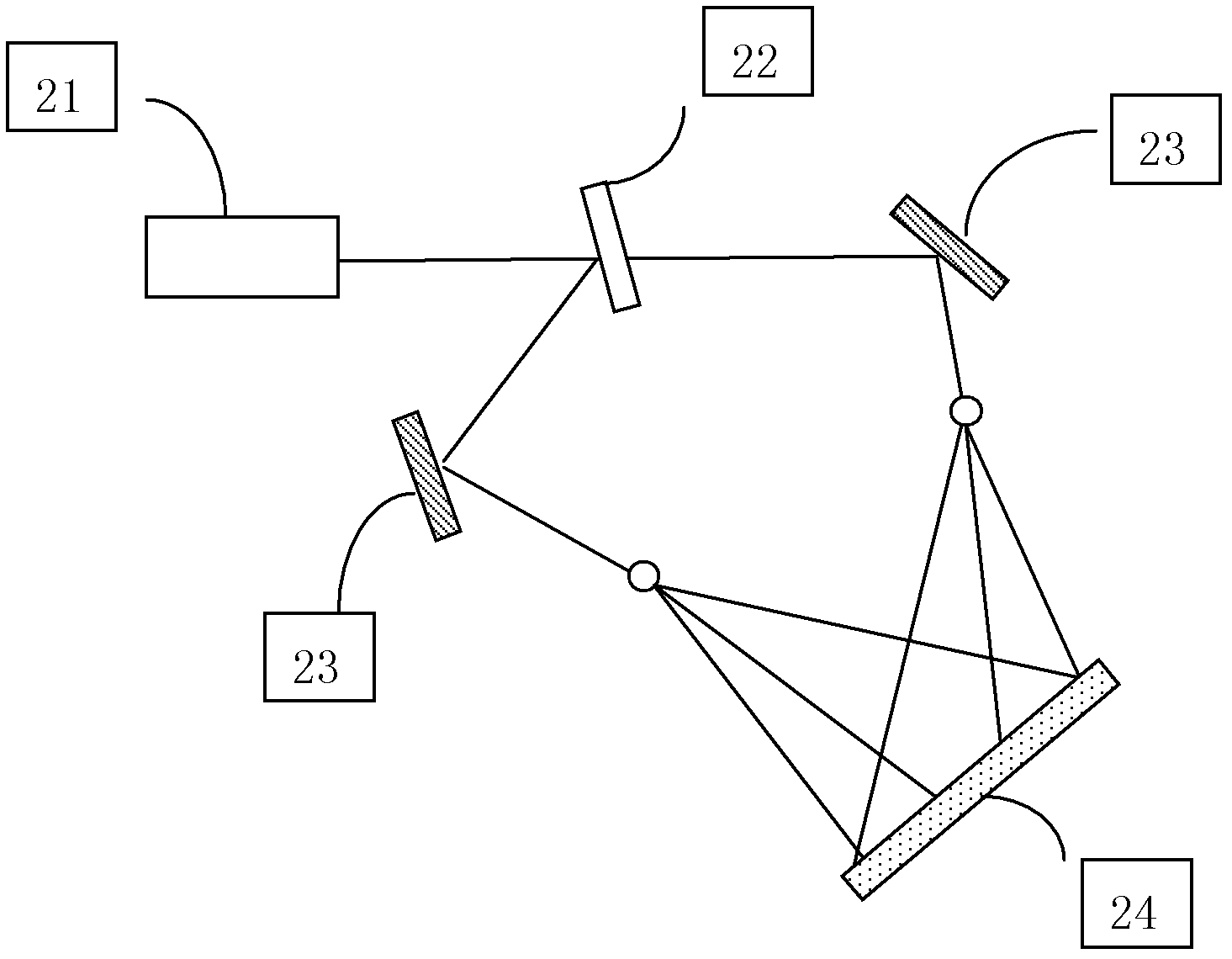

[0033] The aforementioned metal grating is prepared by laser holographic lithography process, and its principle can be found in figure 2 . A laser holographic lithography process is used to form a stripe grating on a photoresist layer evenly coated on the substrate surface. A metal film is formed on the above-mentioned stripe grating by using an electron beam evaporation process, and then the photoresist is strippe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com