Sucrose-free composite nutritional apple and vegetable powder soft candy and preparation method thereof

A vegetable powder and nutritional technology, applied in confectionary, confectionery industry, food science, etc., can solve the problems of unbalanced nutrition and single product, and achieve the effect of rich nutrition and pleasant flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

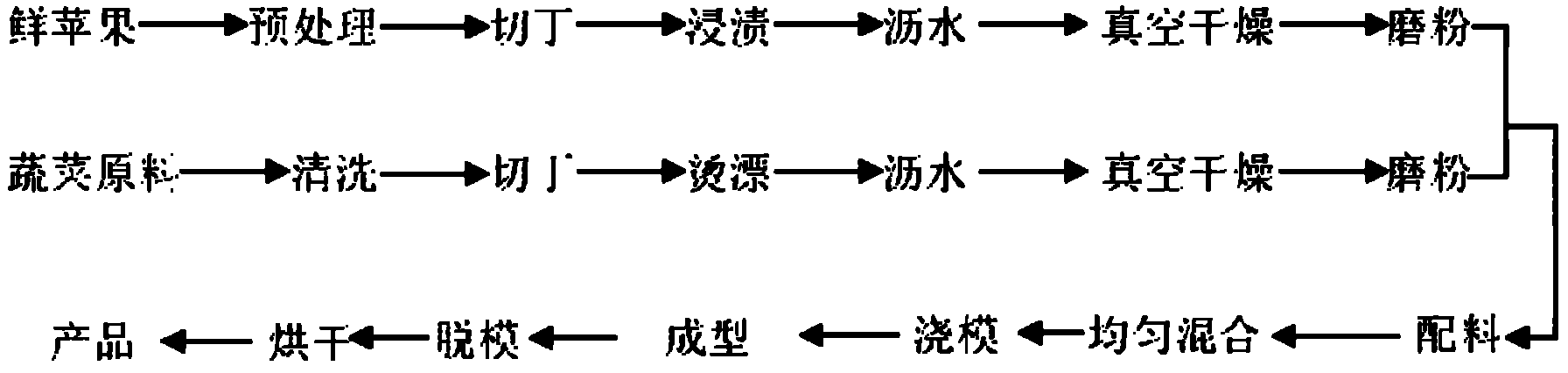

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: produce apple yam powder soft candy

[0024] The soft candy is composed of the following components by weight percentage: 35% of apple powder, 25% of yam powder and 40% of wet gum.

[0025] 1) Preparation of apple powder: using fresh apples as raw materials, first wash the apples with clean water, then soak them in 1.5% HCl aqueous solution at 35°C for 5 minutes, then spray with clean water, wash and drain, and wash After peeling the apples, removing the inedible parts of the pedicles and cores, the apples are then cut into diced apples of 9mm square; the diced apples are placed in a vacuum tank, and the vacuum solid impregnation is carried out with isomaltooligosaccharide water as the impregnating solution. Take out, drain the surface water, the mass fraction of the isomaltose oligosaccharide water is 45%, the time of vacuum solid impregnation is 30min, then transfer to vacuum drying in a vacuum drying oven to obtain crisp apples, The pressure is 10kPa, ...

Embodiment 2

[0031] Embodiment 2: produce apple carrot powder fudge

[0032] The soft candy is composed of the following components by weight percentage: 40% of apple powder, 15% of carrot powder and 45% of wet gum.

[0033] 1) Preparation of apple powder: using fresh apples as raw materials, first wash the apples with clean water, then soak them in 1% HCl aqueous solution at 37°C for 3 minutes, then spray them with clean water, wash them and drain them. After the apples are peeled, the pedicles and the inedible parts of the cores are removed, the apples are then cut into diced apples of 8 mm square; Take out, drain the surface water, the mass fraction of the isomaltose oligosaccharide water is 50%, the time of vacuum solid impregnation is 60min, then transfer to vacuum drying in a vacuum drying oven to obtain crisp apples, The pressure is 1kPa, and the heating temperature in the vacuum drying oven is 50°C; finally, the diced apples are ground to obtain apple powder with an average partic...

Embodiment 3

[0039] Embodiment 3: produce apple celery powder soft candy

[0040] The soft candy is composed of the following components by weight percentage: 35% of apple powder, 15% of celery powder and 50% of wet gum.

[0041] 1) Preparation of apple powder: using fresh apples as raw materials, firstly wash the apples with clean water, then soak them in 1.5% HCl aqueous solution at 30°C for 3 minutes, then spray them with clean water, wash them and drain them. After peeling the apples, removing the inedible parts of the pedicles and cores, the apples are then cut into diced apples of 9mm square; the diced apples are placed in a vacuum tank, and the vacuum solid impregnation is carried out with isomaltooligosaccharide water as the impregnating solution. Take it out, drain the surface water, the mass fraction of the isomaltooligosaccharide water is 40%, the time of vacuum solid impregnation is 50min, then transfer to the vacuum drying oven for vacuum drying to obtain apple crisps, the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com