Photoactivation preparation method for nano-AgCl/Ag visible-light catalyst

A catalyst, visible light technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of difficult to achieve multiple recycling of catalysts, low effective utilization of solar energy, and easy damage to operators. problem, to achieve good application prospects, simple method, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Measure about 60mL of ethylene glycol, add 0.41g of polyvinylpyrrolidone, heat the solution to about 25°C in a constant temperature water bath and dissolve the polyvinylpyrrolidone completely under stirring;

[0036] (2) add 0.348g sodium chloride in above-mentioned solution, make sodium chloride dissolve completely under stirring;

[0037] (3) Dissolve 0.428g of silver nitrate in about 5mL of ethylene glycol solution;

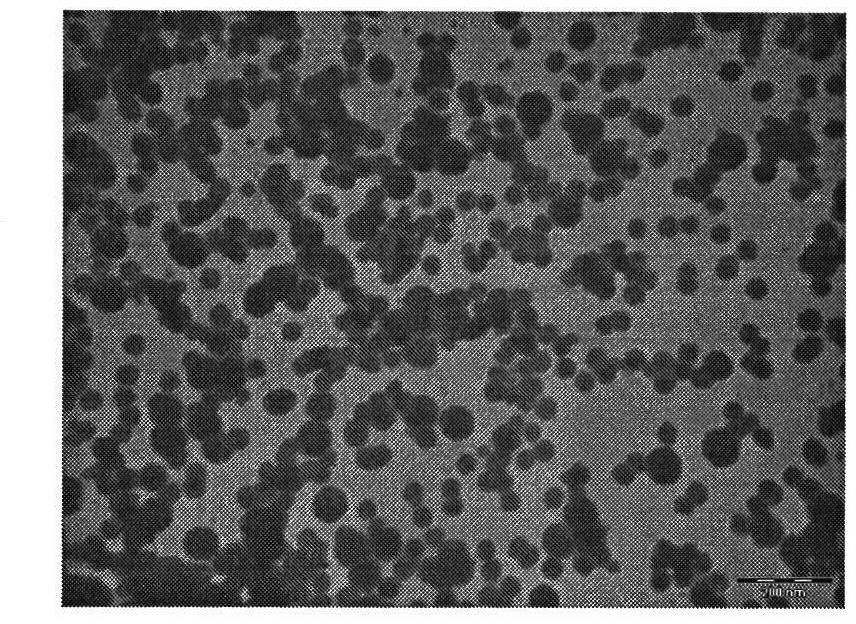

[0038] (4) adding the ethylene glycol solution obtained in step (3) dropwise to the solution obtained in step (2), allowing the reaction to continue for 30 min at 25° C. to obtain spherical AgCl nanoparticles;

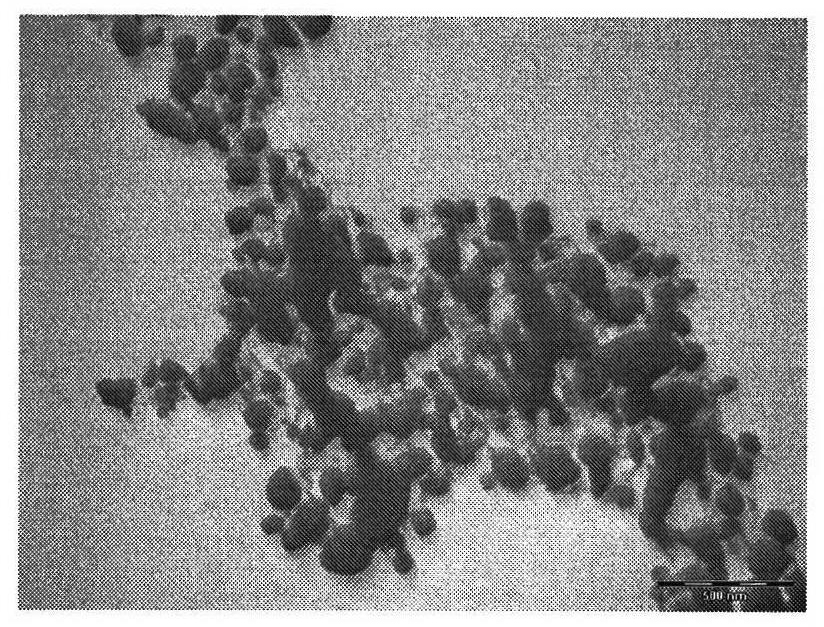

[0039] (5) Place the prepared AgCl nanoparticles together with the mother liquor under a 25W Philips cold light source fluorescent lamp and irradiate for about 30 minutes while stirring, and it can be seen that the milky white suspension gradually turns into a blue-purple suspension;

[0040] (6) Centrifuge the blue-purple suspension at 10,...

Embodiment 2

[0045] (1) Measure about 60mL of ethylene glycol, add 0.28g of polyvinylpyrrolidone, heat the solution to about 50°C in a constant temperature water bath and dissolve the polyvinylpyrrolidone completely under stirring;

[0046] (2) add 0.226g sodium chloride in above-mentioned solution, make sodium chloride dissolve completely under stirring;

[0047] (3) Dissolve 0.286g of silver nitrate in about 5mL of ethylene glycol solution;

[0048] (4) adding the ethylene glycol solution obtained in step (3) dropwise to the solution obtained in step (2), allowing the reaction to continue for 20 min at 50° C. to obtain spherical AgCl nanoparticles;

[0049] (5) Place the prepared AgCl nanoparticles together with the mother liquor under a 25W Philips cold light source fluorescent lamp and irradiate for about 20 minutes while stirring, and it can be seen that the milky white suspension gradually turns into a blue-purple suspension;

[0050] (6) Centrifuge the blue-purple suspension at 10,...

Embodiment 3

[0053] (1) Measure about 60mL of ethylene glycol, add 0.14g of polyvinylpyrrolidone, heat the solution to about 80°C in a constant temperature water bath and dissolve the polyvinylpyrrolidone completely under stirring;

[0054] (2) add 0.113g sodium chloride in above-mentioned solution, make sodium chloride dissolve completely under stirring;

[0055] (3) Dissolve 0.143g of silver nitrate in about 5mL of ethylene glycol solution;

[0056] (4) adding the ethylene glycol solution obtained in step (3) dropwise to the solution obtained in step (2), allowing the reaction to continue for 10 min at 80° C. to obtain spherical AgCl nanoparticles;

[0057] (5) The prepared AgCl nanoparticles are centrifugally separated from the mother liquor at 10000rpm and then dispersed into 50mL of deionized water;

[0058] (6) The solution obtained in step (5) is irradiated for about 10 minutes while stirring under a 25W Philips cold light source fluorescent lamp, and it can be seen that the milky ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com