Method for preparing potassium chloride from solid kali salt mine through rotating decomposition and positive flotation

A production method and technology of potash mines, applied in the direction of alkali metal chloride, etc., can solve the problems of uncontinuous production of coarse grain sinks and blockage of material conveying, and achieve large production capacity, low production energy consumption and good process stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

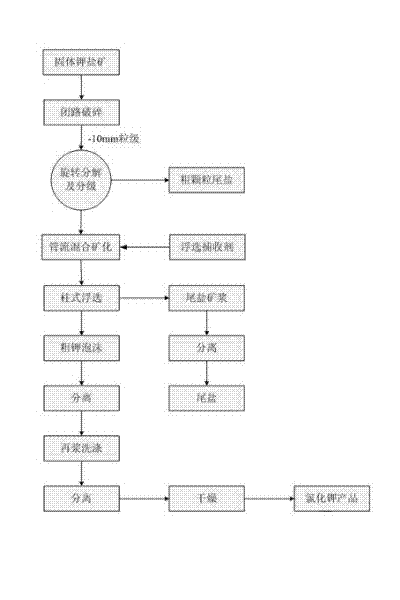

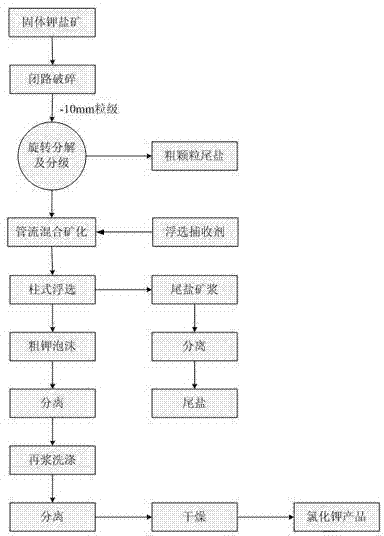

Method used

Image

Examples

Embodiment 1

[0025] Underground mining of solid potash ore is 1.00 tons per hour, and the continuous production is 10 hours.

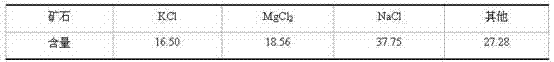

[0026] (1) The chemical composition of the comprehensive mineral sample is:

[0027]

[0028] (1) Broken

[0029] The purpose of crushing is to control the particle size of potash ore within -10mm, and to provide raw materials with suitable particle size for rotary decomposition.

[0030] (2) Rotation decomposition and classification

[0031] In the rotary decomposer, the ore cast is 1 ton / hour, the amount of water added is 0.40 ton / hour, and the mother liquor is added to be 0.38 ton / hour. The decomposition temperature is 28-34°C, and the rotating speed of the rotary decomposer is 44 rpm; the concentration of the pulp obtained by decomposition is 24.38%, and the average potassium chloride content of the classified coarse-grained sodium chloride rock salt is 1.17%.

[0032] (3) Pipe flow mineralization

[0033] The ore pulp obtained from the rotary cold decom...

Embodiment 2

[0039] Underground mining of solid potash ore has a ore input of 2.16 tons / hour and continuous production for 6 hours.

[0040] (1) The typical chemical composition of solid potash ore mined underground is:

[0041]

[0042] (2) Broken

[0043] The purpose of crushing is to control the particle size of potash ore within -10mm, and to provide raw materials with suitable particle size for rotary decomposition.

[0044] (3) Rotation decomposition and classification

[0045] The ore cast in the rotary decomposer is 2.16 tons / hour, the amount of water added is 0.83 tons / hour, and the addition of mother liquor is 0.43 tons / hour. The decomposition temperature is 28~34℃, and the rotating speed of the rotary decomposer is 30 rpm; the concentration of the pulp obtained by the decomposition is 25.54%, and the average potassium chloride content of the classified coarse-grained sodium chloride rock salt is 1.72%.

[0046] (4) Pipe flow mineralization

[0047] The ore pulp obtained fro...

Embodiment 3

[0053] Underground mining of solid potash ore has a ore input of 1.57 tons / hour and continuous production for 9 hours.

[0054] (1) The typical chemical composition of solid potash ore mined underground is:

[0055]

[0056] (2) Broken

[0057] The purpose of crushing is to control the particle size of potash ore within -10mm, and to provide raw materials with suitable particle size for rotary decomposition.

[0058] (3) Rotation decomposition and classification

[0059] The ore cast in the rotary decomposer is 1.57 tons / hour, the amount of water added is 0.65 tons / hour, and the addition of mother liquor is 0.88 tons / hour, the above-mentioned solid potash ore is decomposed in the rotary decomposer, and the time of decomposition is controlled to be 0.50 hours, The decomposition temperature is 30-32°C, and the rotating speed of the rotary decomposer is 15 rpm; the concentration of the decomposed pulp is 31.90%, and the average potassium chloride content of the graded coarse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com