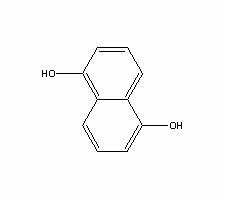

Method for producing 1,5-dihydroxy naphthalene

A technology of dihydroxynaphthalene and a production method, which is applied in chemical instruments and methods, inorganic chemistry, preparation of organic compounds, etc., can solve the problems of large processing capacity of mother liquor, difficult processing, difficult distillation of dilute sulfuric acid, etc., and achieves reduction of energy consumption. , the effect of simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

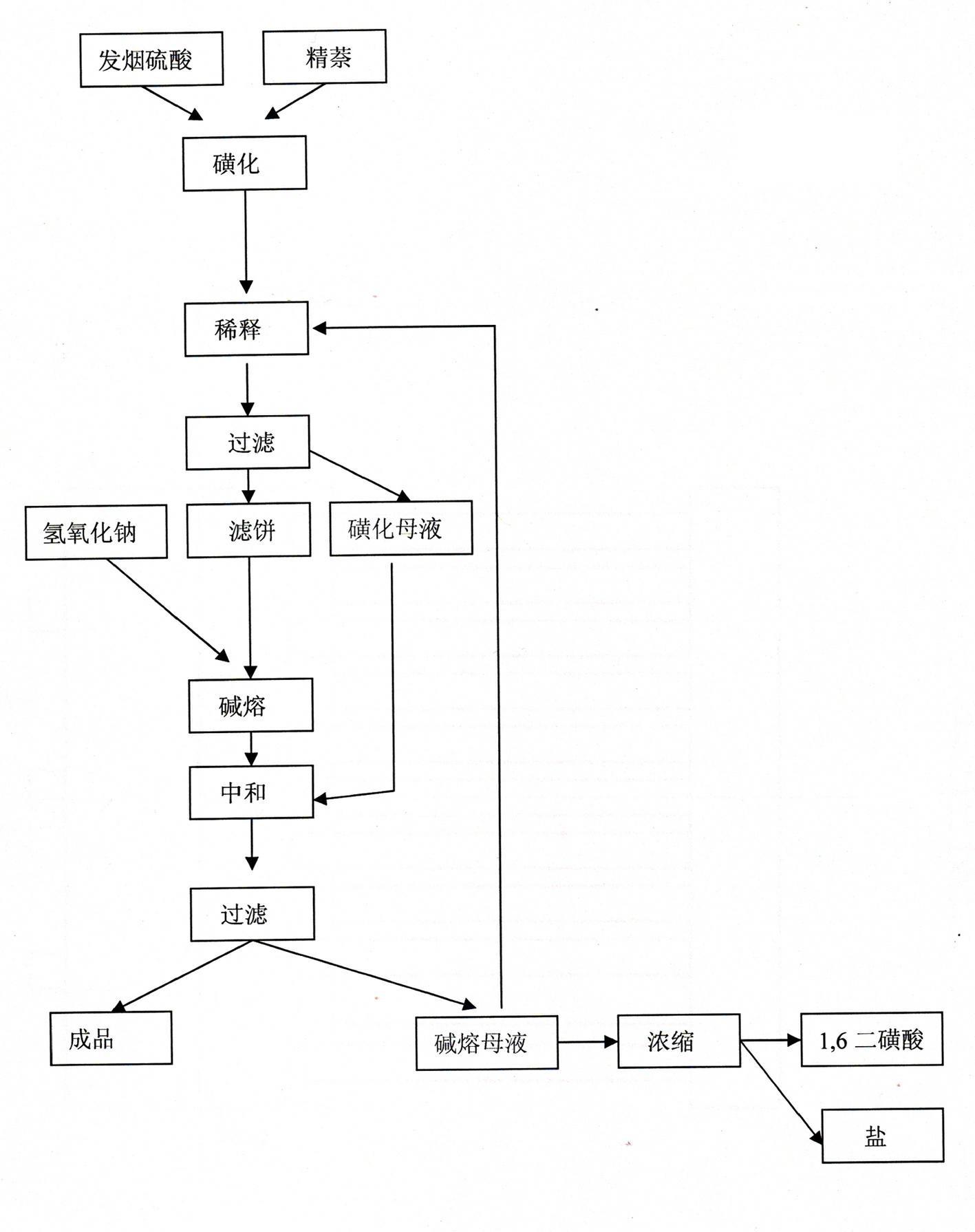

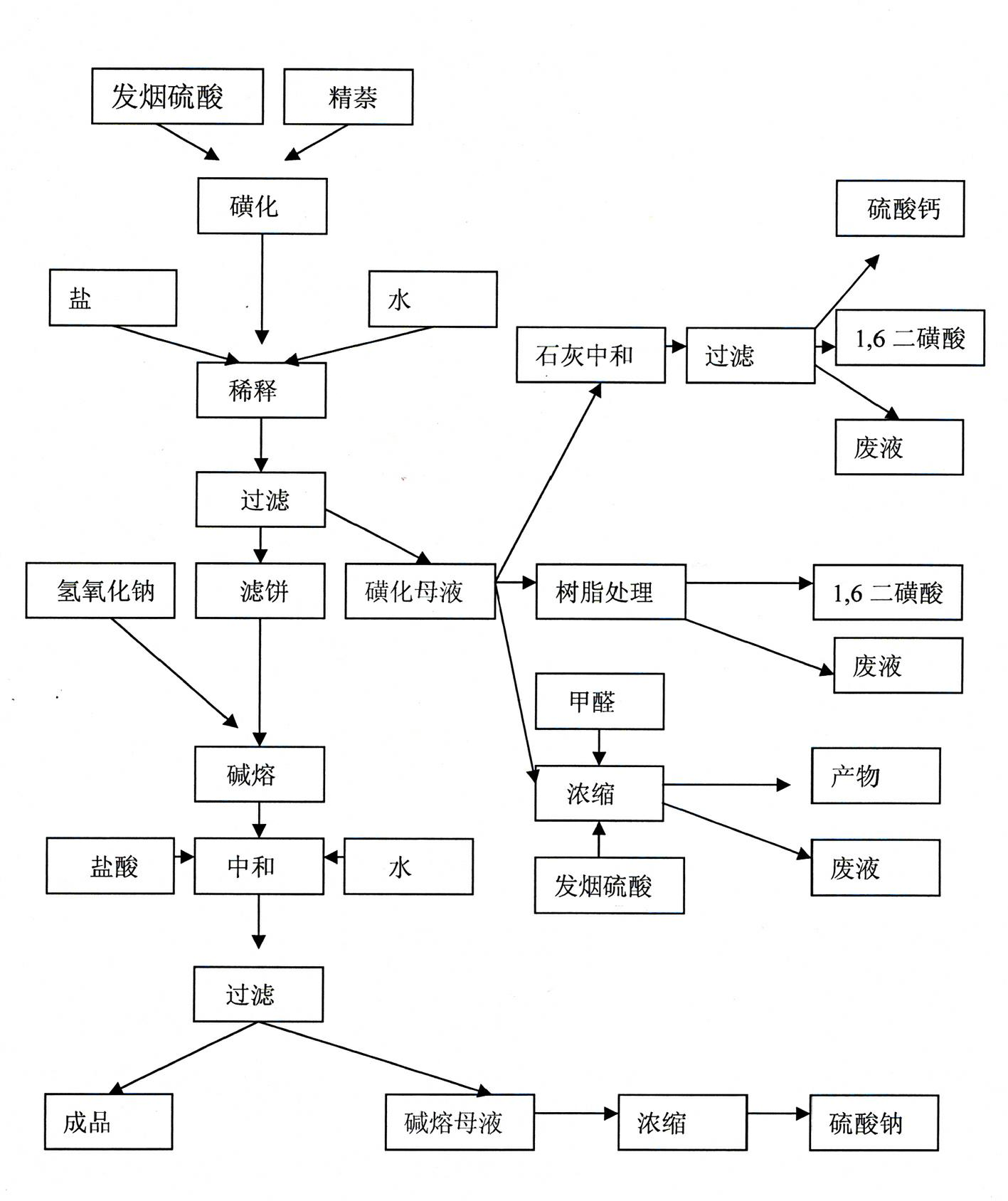

Method used

Image

Examples

Embodiment 1

[0052] 1 Add 2300 kilograms of 20% fuming sulfuric acid in the reactor with stirring, then evenly add 400 kilograms of refined naphthalene;

[0053] 2 Then add the obtained sulfonated product to 2000 liters of the alkali fusion mother liquor obtained from the previous batch and prepared with a sodium sulfate concentration of 10%, and control the temperature to 40°C;

[0054] 3 Filtration to obtain 608 kg of 1,5 naphthalene disulfonic acid and sulfonated mother liquor, liquid chromatography analysis, 1,5 naphthalene disulfonic acid content 90%, yield 60%;

[0055] 4 Alkali fusion: react the filter cake of 1,5 naphthalene disulfonic acid with sodium hydroxide to generate an alkali fusion product;

[0056] 5 Neutralization: Add the sulfonated mother liquor to the alkali fusion product, add concentrated sulfuric acid to adjust the pH to 5.0, and the temperature is 60°C;

[0057] 6 Filtration: 1,5 dihydroxynaphthalene was obtained, the weight after drying was 250 kg, and the conte...

Embodiment 2

[0060] 1 Add 2300 kilograms of 20% fuming sulfuric acid in the reactor with stirring, then evenly add 400 kilograms of refined naphthalene,

[0061]2 Then add the obtained sulfonated product to 2500 liters of the alkali fusion mother liquor obtained from the previous batch and prepared with a sodium sulfate concentration of 15%, and control the temperature at 60°C;

[0062] 3 Filtration to obtain 653 kg of 1,5 naphthalene disulfonic acid and sulfonated mother liquor. Liquid chromatography analysis, 1,5 naphthalene disulfonic acid content 88%, yield 63%;

[0063] 4 Alkali fusion: react the filter cake of 1,5 naphthalene disulfonic acid with sodium hydroxide to generate an alkali fusion product;

[0064] 5 Neutralization: Add the sulfonated mother liquor to the alkali fusion product, add concentrated sulfuric acid to adjust the pH to 5.5, and the temperature is 80°C;

[0065] 6 Filtration: 1,5 dihydroxynaphthalene was obtained, the weight after drying was 260 kg, and the conte...

Embodiment 3

[0068] 1 Add 2300 kilograms of 20% fuming sulfuric acid in the reactor with stirring, then evenly add 400 kilograms of refined naphthalene;

[0069] 2 Then add the obtained sulfonated product to 3000 liters of the alkali fusion mother liquor obtained from the previous batch and prepared with a sodium sulfate concentration of 25%, and control the temperature at 80°C;

[0070] 3 Filtration to obtain 683 kg of 1,5 naphthalenedisulfonic acid and sulfonated mother liquor. Liquid chromatography analysis, 1,5 naphthalene disulfonic acid content 87%, yield 65%;

[0071] 4 Alkali fusion: react the filter cake of 1,5 naphthalene disulfonic acid with sodium hydroxide to generate an alkali fusion product;

[0072] 5 Neutralization: Add the sulfonated mother liquor to the alkali fusion product, add concentrated sulfuric acid to adjust the pH to 6.0, and the temperature is 80°C;

[0073] 6 Filtration: 1,5 dihydroxynaphthalene was obtained, the weight after drying was 260 kg, and the conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com