Anti-cracking putty

An anti-cracking putty and raw material technology, applied in the direction of filling slurry, etc., can solve the problems of easy curling of the wall surface, short service life, poor adhesion, etc., and achieve good workability, convenient construction, and improved adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] An anti-cracking putty is uniformly prepared by high-speed dispersion and stirring of the following raw materials according to the weight ratio: 75 parts of polyurethane resin, 30 parts of polypropylene short fiber, 2 parts of dispersant, 2 parts of preservative, 1 part of diatomaceous earth, 15 parts Parts of petroleum ether, 10 parts of sodium carboxymethylcellulose, 5 parts of heavy calcium powder, 6 parts of binder, 10 parts of zinc chromate, 20 parts of zinc oxide, and 5 parts of thickener.

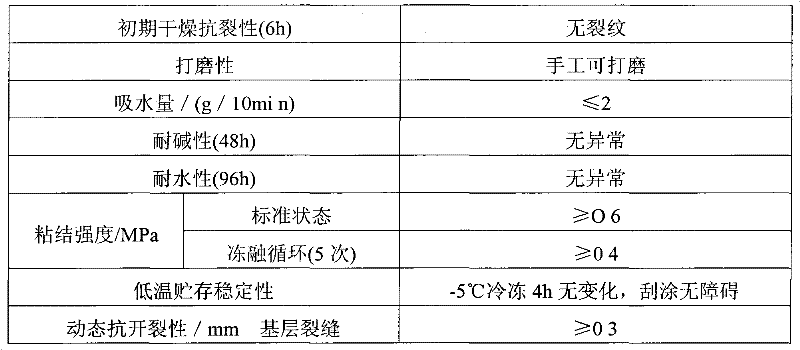

[0009] The main technical properties of the product prepared by the present invention are shown in Table 1 below.

[0010] Table 1, main technical performance of the present invention

[0011]

[0012]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com