Pressure reduction distillation process method

The technology of vacuum distillation tower and vacuum furnace is applied in the vacuum distillation process of crude oil, and the vacuum distillation process field of improving the extraction rate of crude oil vacuum distillation process, which can solve the problem of high load of the top vacuum system and high energy consumption of the device. , complex tower structure and other problems, to achieve the effect of less equipment renovation, low investment and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The process of the invention is used in the design of a newly-built crude oil vacuum distillation unit.

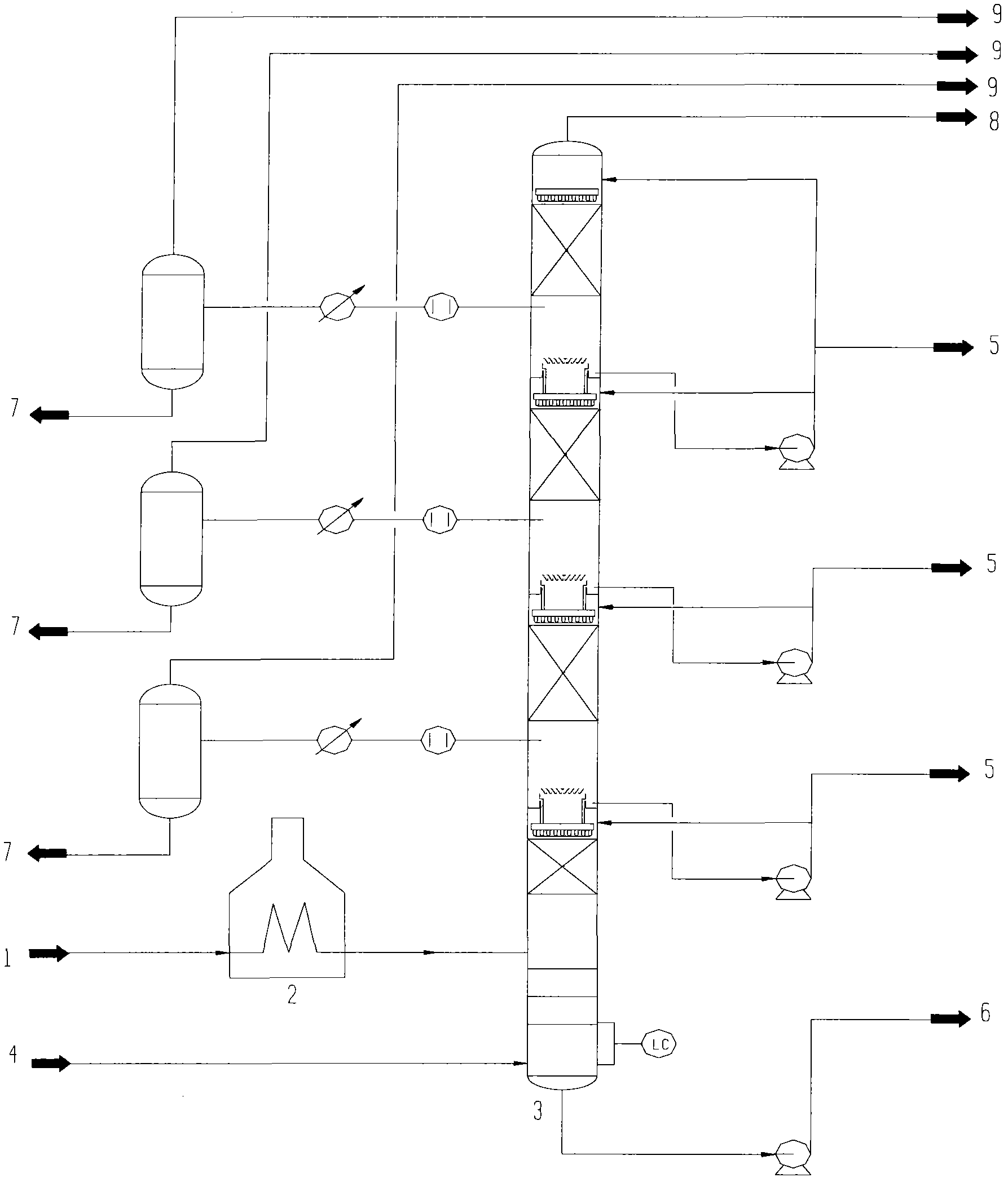

[0037] The vacuum distillation process includes a vacuum furnace, a vacuum distillation tower, a gas-liquid separation tank for gas phase production, and vacuuming of the tower top and the tank top. The vacuum distillation tower is a structured packing tower, operated by a wet process, the bottom steam blowing volume is 1% of the tower feed mass, the top operating pressure is 1315kPa, and the pressure drop of the whole tower is 300Pa~500Pa. Using Kuwait atmospheric heavy oil as raw material, the vacuum distillation unit has a processing capacity of 1.2 million tons per year.

[0038] Atmospheric oil is fed into the vacuum distillation unit at a rate of 120 tons / hour, heated to 390℃~400℃ in the vacuum furnace, and then enters the vacuum distillation tower. The side stream product is withdrawn from the vacuum distillation tower. The vacuum residue is discharged from the ...

Embodiment 2

[0044] The method of the present invention is used for the expansion and transformation of a crude oil atmospheric and vacuum unit. The atmospheric part is the same as the conventional atmospheric and vacuum unit. The vacuum part mainly includes a vacuum furnace, a vacuum distillation tower, a gas-phase production gas-liquid separation tank, and a tower Vacuum top and tank top.

[0045] The vacuum distillation tower is a structured packing tower, operated by a wet process, the bottom steam blowing volume is 1% of the tower feed, the top operating pressure is 1.315kPa, and the pressure drop of the whole tower is 300Pa~500Pa. Using Kuwait atmospheric heavy oil as raw material, the vacuum distillation unit has a processing capacity of 1.2 million tons per year.

[0046] Atmospheric oil is fed into the vacuum distillation unit at a rate of 120 tons / hour, heated to 390℃~400℃ in the vacuum furnace, and then enters the vacuum distillation tower. The side stream product is withdrawn from ...

Embodiment 2 approach A

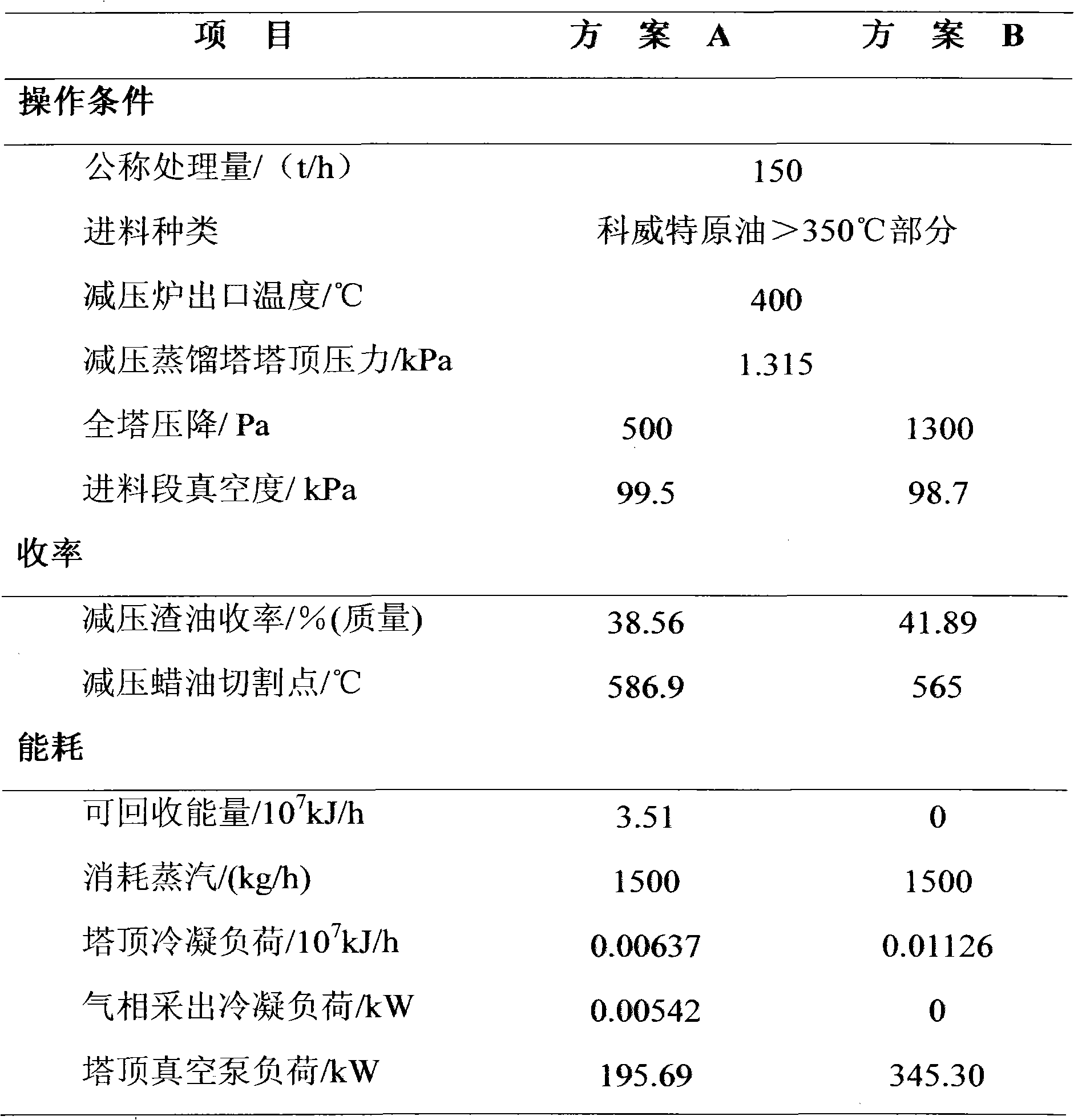

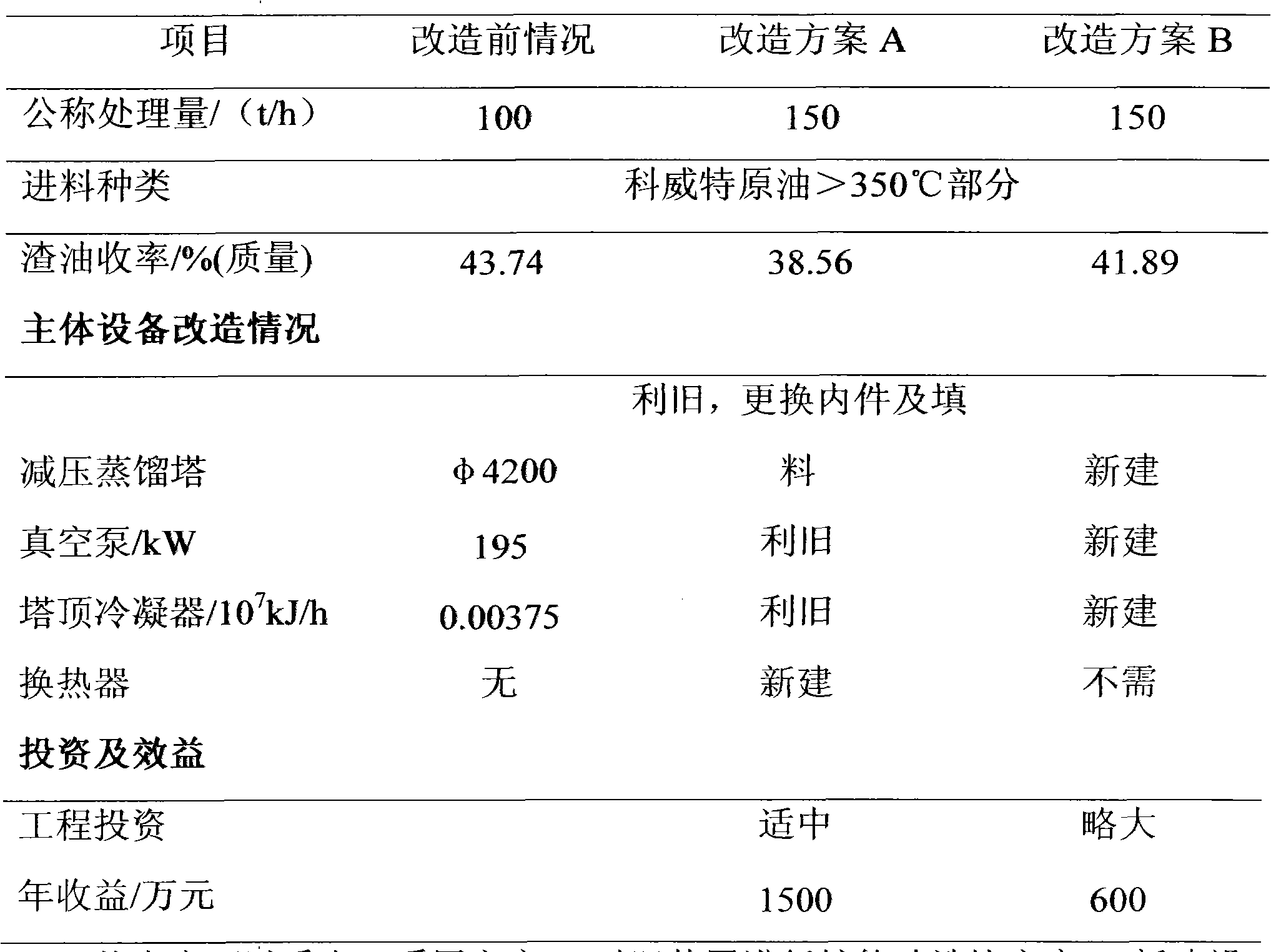

[0049] Table 2 Comparison of Scheme A and Scheme B in Example 2

[0050]

[0051] It can be seen from the table that the use of plan A to expand the capacity of the old device is less than that of plan B to build new equipment, and the amount of engineering renovation is small, so the project investment is less, the renovation period is shorter; the equipment income is also significantly better. Plan A has greater rectification advantages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com