Hydrogenation treatment method for high-acid hydrocarbon oil

A technology for hydrotreating and high-acid hydrocarbons, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems of expensive materials, unfavorable deacidification reaction, and increased refining costs, so as to reduce investment and operating costs , avoid high temperature and strong corrosion, and broaden the effect of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

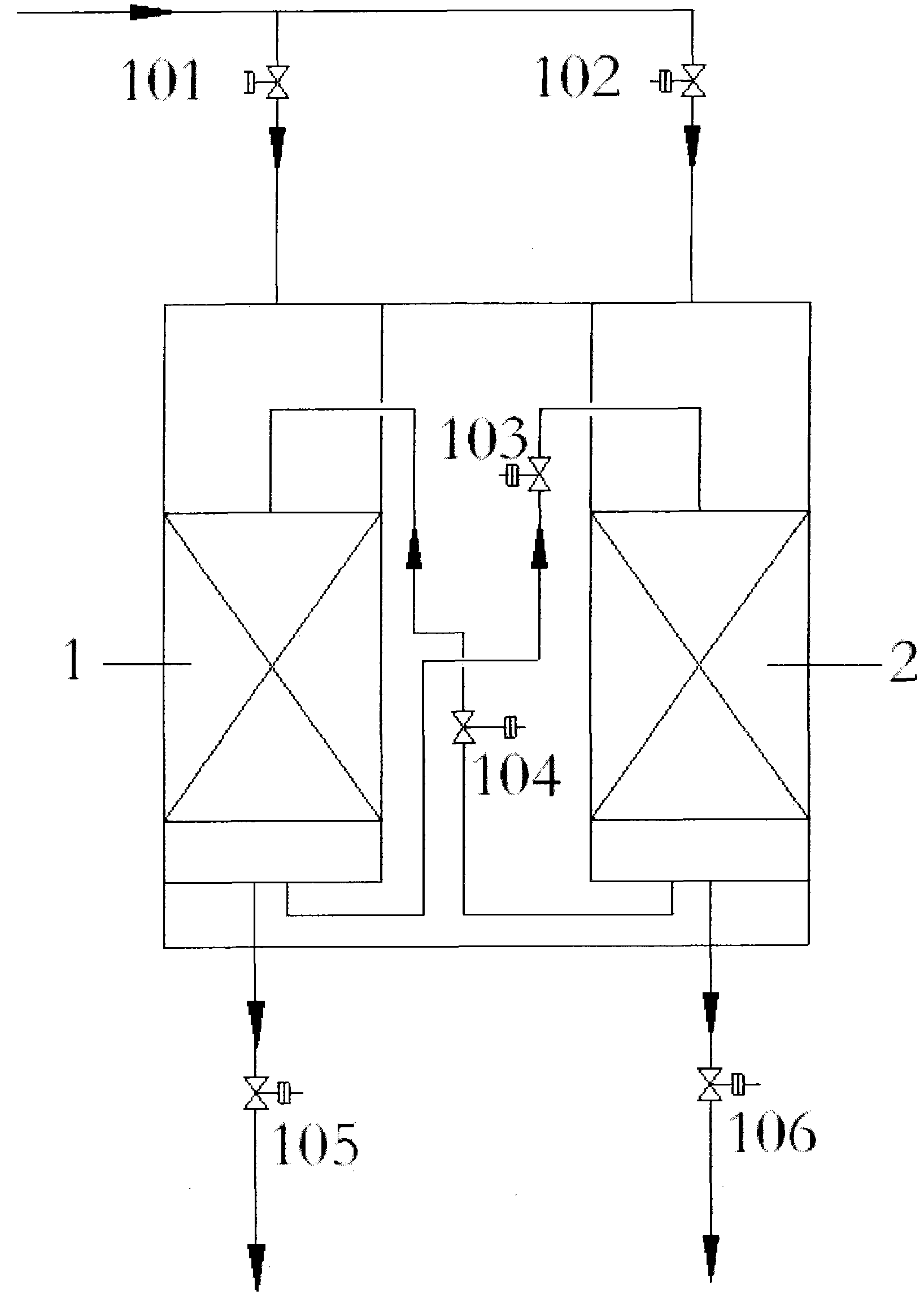

[0028]When starting work, first open the valves 101, 103 and 106, and close the other valves, use high-pressure hot hydrogen to heat up the heat storage body No. 1, and when the temperature of the No. A mixture of high-acid crude oil and hydrogen, so that the No. 1 regenerator of acid-containing crude oil and hydrogen in the fixed-bed reactor is in contact with the hydrogenation catalyst A, at a hydrogen partial pressure of 3.0 MPa, a reaction temperature of 320°C, and a 400Nm 3 / m 3 , liquid hourly space velocity 4.0h -1 The hydrogenation reaction is carried out under certain conditions, and the reaction product flows out of the No. 1 regenerator reactor 1 through the valve 103 and enters the No. 2 regenerator reactor, heats the No. 2 regenerator, and finally flows out of the reactor through 106 into the The No. 2 regenerator stores the heat carried by the reaction effluent to the No. 2 regenerator. When the temperature difference between the outlet temperature and the inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com