Method for preparing porous nanometer alpha-Fe2O3 hollow spheres and application of hollow spheres to low-temperature alcohol sensitivity

A technology of -fe2o3 and hollow spheres, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of material pollution, cost increase, cumbersome preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 0.81gFe(NO 3 ) 3 9H 2 O, 0.18gH 2 C 2 o 4 and 0.24gCO(NH 2 ) 2 Dissolve in 40ml deionized water, mix evenly by magnetic stirring for 30min, then transfer to a 60ml hydrothermal kettle. React the mixed solution at a constant temperature of 140°C for 12 hours, take it out and cool it to room temperature, collect the resulting precipitate, wash it, dry it in vacuum at 40°C, and roast it at 300°C with a programmed temperature increase (2°C / min) to obtain nano-α-Fe 2 o 3 Hollow ball material.

Embodiment 2

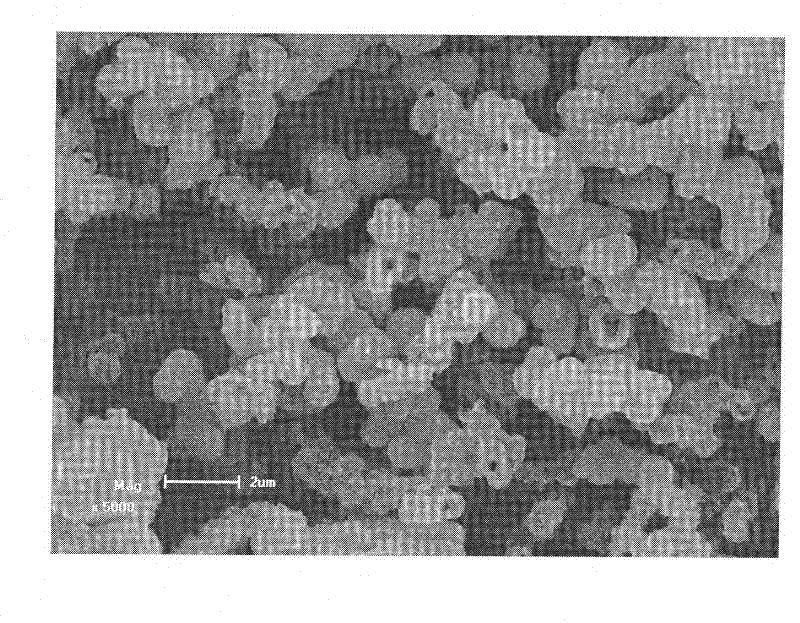

[0025] To the α-Fe that embodiment 1 makes 2 o 3 The hollow ball material is used for SEM experiment, the sample is stuck on the sample stage, and the test is carried out after vacuum gold plating. The X-650 scanning electron microscope of Hitachi, Japan is used, and the working voltage is 25KV. SEM photos as figure 1 shown.

Embodiment 3

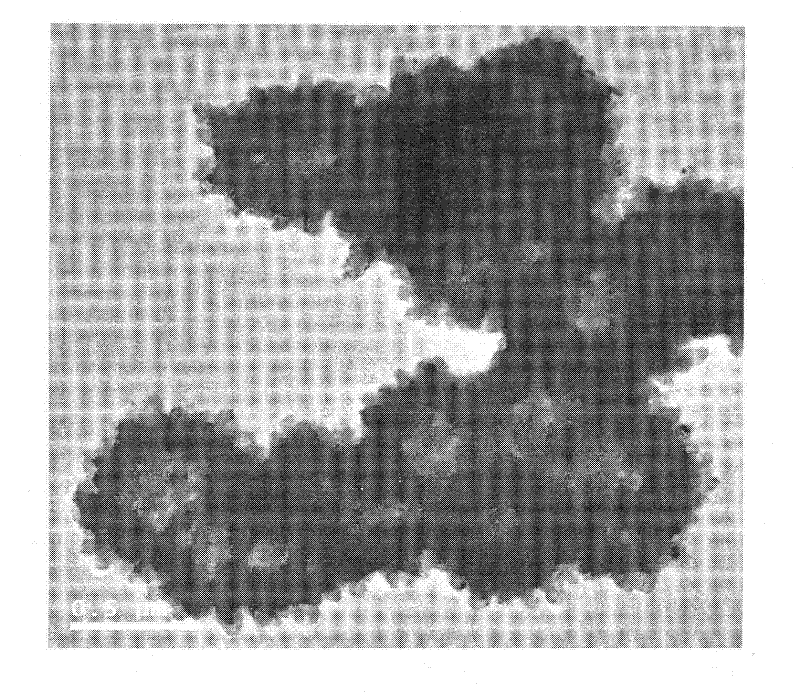

[0027] To the α-Fe that embodiment 1 makes 2 o 3 Perform TEM experiment on hollow spherical material, take a small amount of α-Fe that has been fully ground 2 o 3 The hollow sphere material is ultrasonically dispersed in absolute ethanol, and a small amount of the above-dispersed suspension is dropped on a copper grid with a dropper, dried (~10min), and tested under a Philips T20ST electron microscope with a working voltage of 200kV. TEM photos such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com