Method and device for sewage treatment and recovery

A sewage treatment and recovery method technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of sewage treatment with half the effort and difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

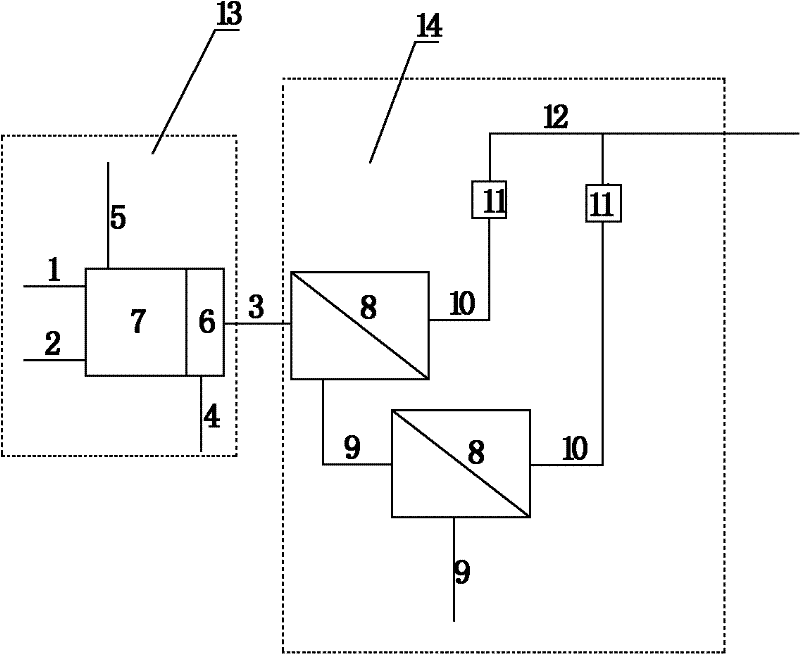

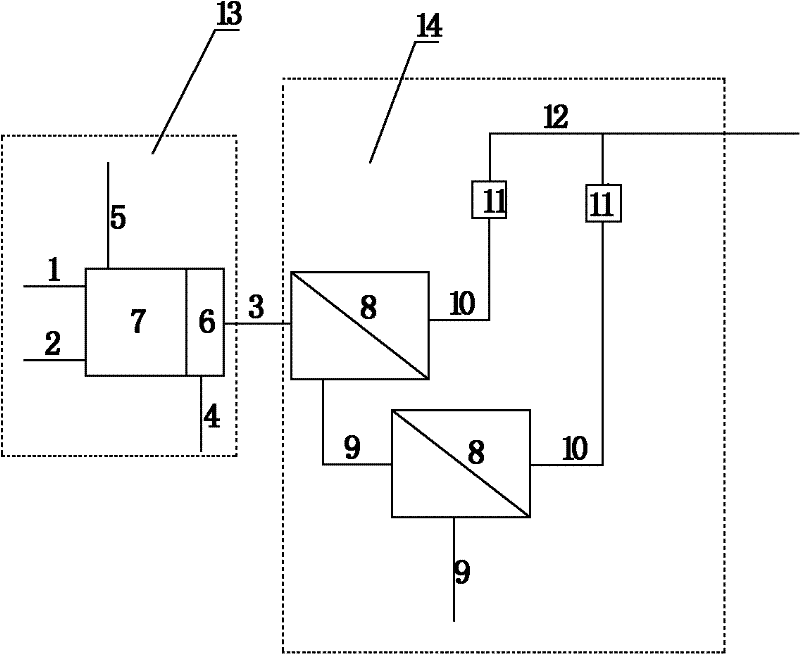

Method used

Image

Examples

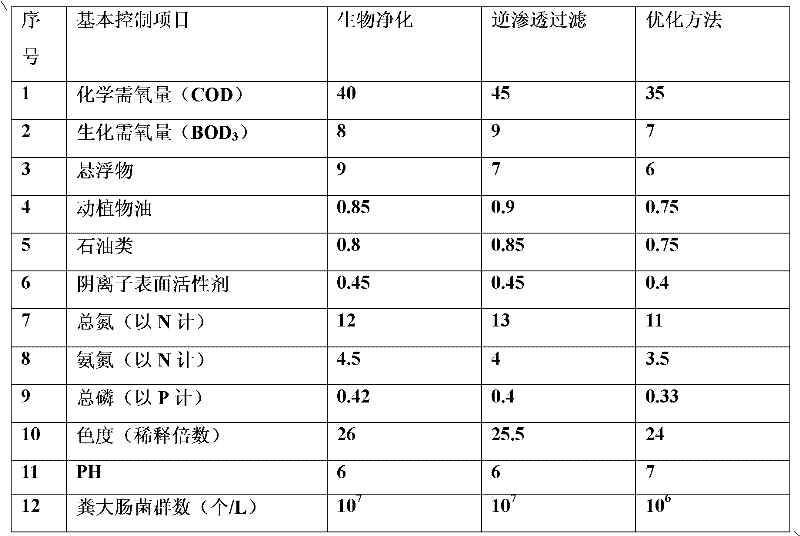

Embodiment 1

[0056] Example 1: Cultivate mature activated sludge: sewage enters the activation tank through the water input pipe, adjust the sewage BOD5 to 200mg / L, and carry out continuous aeration at 15-20°C, the activated sludge flocs continue to increase, and after one week When the aeration is stopped, the sedimentation is static for 1 hour, and the supernatant liquid accounting for 60% of the total volume is discharged, the sewage water inflow is adjusted, and the aeration is continued until the sedimentation ratio is close to 30%, and the cultivation is completed. Then add polyurethane foam microbial carrier to the sewage to be treated so that its concentration in the sewage is 10g / L, and finally add biologically active sludge to make the sludge concentration of the whole purification system reach 15g / L, and continue to pass through the sludge containing After 6 hours of oxygen gas, biological purification is carried out for 24 hours; after the sewage is treated by biological purific...

Embodiment 2

[0057] Example 2: Cultivate mature activated sludge: sewage enters the activation tank through the water input pipe, adjust the sewage BOD5 to 250mg / L, and carry out continuous aeration at 15-20°C, the activated sludge flocs continue to increase, and after one week When the aeration is stopped, the sedimentation is still for 1.2 hours, and the supernatant liquid accounting for 65% of the total volume is discharged, the sewage water inflow is adjusted, and the aeration is continued until the sedimentation ratio is close to 30%, and the cultivation is completed. Then add polypropylene foam microbial carrier to the sewage to be treated so that its concentration in the sewage is 10g / L, and finally add biologically active sludge to make the sludge concentration of the whole purification system reach 15g / L, and pass through the sewage containing Oxygen gas is used for biological purification; after the sewage is treated by biological purification, it enters the five sets of sewage fi...

Embodiment 3

[0058] Example 3: Cultivate mature activated sludge: sewage enters the activation tank through the water input pipe, adjust the sewage BOD5 to 300mg / L, and carry out continuous aeration at 15-20°C, the activated sludge flocs continue to increase, and after one week When the aeration is stopped, the sedimentation is still for 1.5 hours, and the supernatant liquid accounting for 70% of the total volume is discharged, the amount of sewage inflow is adjusted, and the aeration is continued until the sedimentation ratio is close to 30%, and the cultivation ends. Then add polypropylene foam microbial carrier to the sewage to be treated, so that its concentration in the sewage is 10g / L, and finally add biologically active sludge to make the sludge concentration of the whole purification system reach 15g / L, and continue to feed After 6 hours of oxygen-containing gas, biological purification is carried out for 24 hours; after the sewage is treated by biological purification, it enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com