Highly water-absorbing antibacterial fiber

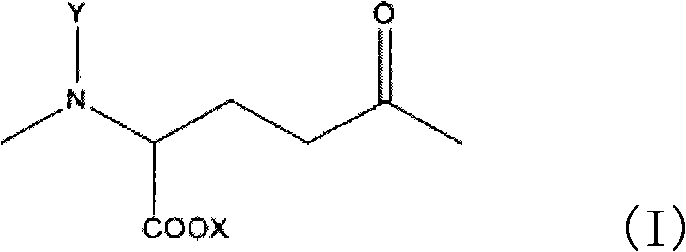

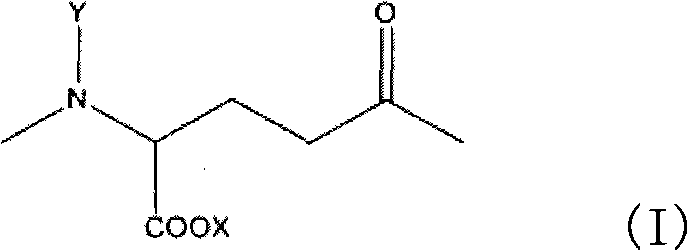

A technology of water absorption and fiber, applied in the chemical post-treatment of synthetic polymer rayon filament, single-component polyamide rayon filament, single-component copolyamide rayon filament, etc., can solve problems such as inapplicability, achieve Good water absorption, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

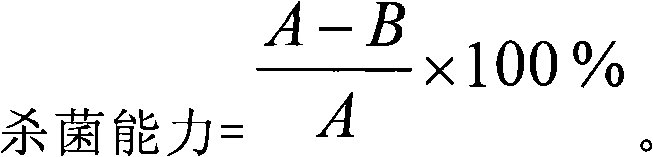

[0037] Soak the polyglutamic acid fiber in 0.3wt% sodium hypochlorite aqueous solution, adjust the pH value between 6-8 with 0.5N phosphoric acid aqueous solution, take it out after soaking for 1 minute. Rinse the fiber with secondary water, let it stand to dry, and then use X-ray energy dispersive analyzer (EDS) to detect the increase ratio of chloride ions before and after soaking, so as to measure the difference between the modified polyglutamic acid segment and the unmodified polyglutamic acid segment. The content ratio of the modified polyglutamic acid segment.

Embodiment 2

[0039] Soak the polyglutamic acid fiber in 0.16wt% sodium hypochlorite aqueous solution, adjust the pH value between 6-8 with 0.5N phosphoric acid aqueous solution, take it out after soaking for 4 minutes. Rinse the fiber with secondary water, let it stand until it dries, and then use an X-ray energy dispersive analyzer (EDS) to detect the increase ratio of chloride ions before and after soaking to measure the modified polyglutamic acid chain segment and The content ratio of unmodified polyglutamic acid segment.

Embodiment 3

[0041] Soak the polyglutamic acid fiber in 0.078wt% sodium hypochlorite aqueous solution, adjust the pH value between 6-8 with 0.5N phosphoric acid aqueous solution, take it out after soaking for 7 minutes. Rinse the fiber with secondary water, let it stand to dry, and then use X-ray energy dispersive analyzer (EDS) to detect the increase ratio of chloride ions before and after soaking, so as to measure the difference between the modified polyglutamic acid segment and the unmodified polyglutamic acid segment. The content ratio of the modified polyglutamic acid segment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com