Preparation method of silicon-dioxide-coated titanium dioxide hollow core-shell structural material

A titanium dioxide and silicon dioxide technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of difficult industrialization, cumbersome processes, expensive reagents, etc., and achieves low cost, method and process flow. Simple, actionable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

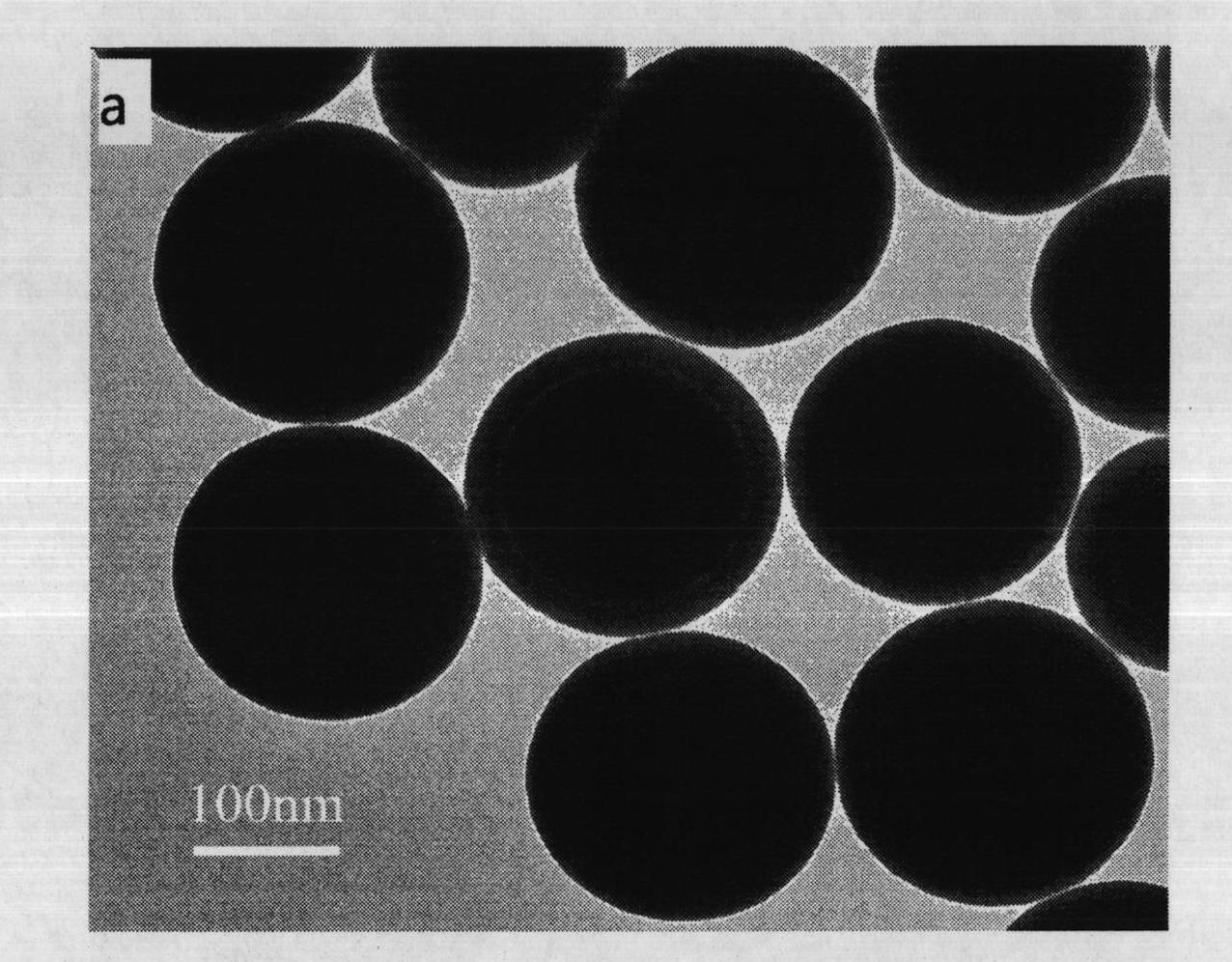

Image

Examples

Embodiment 1

[0027] Dissolve 5g of orthotitanic acid in 30% aqueous hydrogen peroxide solution with 5ml mass percent concentration to obtain titanium peroxide aqueous solution, adjust the pH=10 of titanium peroxide aqueous solution with 2.5% mass percent concentration; under stirring conditions, Add 10 ml of titanium peroxide aqueous solution with a pH value of 10 to 60 ml of ethanol, add 5 ml of tetrahexyloxysilane with a mass percent concentration of 28% at a temperature of 80° C., and mechanically stir and reflux for 4 hours to obtain Emulsion of silica-coated titanium dioxide hollow core-shell structure material; the prepared emulsion containing silica-coated titanium dioxide hollow core-shell structure material is centrifugally precipitated, and the obtained precipitate is washed with pure water and ultrasonicated in pure water Re-disperse and re-centrifuge to precipitate, preferably repeat the above washing steps three times; then wash the obtained precipitate with absolute ethanol an...

Embodiment 2

[0030] Dissolve 10 g of orthotitanic acid in 30% aqueous hydrogen peroxide with 10 ml of mass percent concentration to obtain a titanium peroxide aqueous solution, adjust the pH=5 of the aqueous titanium peroxide solution with a mass percent concentration of 2.5%; under stirring conditions, 10ml of titanium peroxide solution with a pH value of 5 was added to 60ml of ethanol, and at a temperature of 50°C, 5ml of tetrabutoxysilane with a mass percent concentration of 28% was added, mechanically stirred and refluxed for 12 hours to obtain Emulsion of silica-coated titanium dioxide hollow core-shell structure material; the prepared emulsion containing silica-coated titanium dioxide hollow core-shell structure material is centrifugally precipitated, and the obtained precipitate is washed with pure water and ultrasonicated in pure water Re-disperse and re-centrifuge to precipitate, preferably repeat the above washing steps three times; then wash the obtained precipitate with absolute...

Embodiment 3

[0033] Dissolve 5g of orthotitanic acid in 30% aqueous hydrogen peroxide solution with 5ml mass percentage concentration to obtain titanium peroxide aqueous solution, adjust the pH=7 of titanium peroxide aqueous solution with a mass percentage concentration of 2.5% sodium hydroxide solution; Under certain conditions, 10ml of titanium peroxide solution with a pH value of 7 was added to 60ml of ethanol, and at a temperature of 80-100°C, 5ml of tetrahexyloxysilane with a concentration of 28% by mass was added, and mechanically stirred and refluxed. After 4 hours, an emulsion containing a silica-coated titanium dioxide hollow core-shell structure material was obtained; the prepared emulsion containing a silica-coated titanium dioxide hollow core-shell structure material was centrifugally precipitated, and the obtained precipitate was washed with pure water and Ultrasonic re-dispersion in pure water and then centrifugation again, preferably repeating the above washing steps three ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com