Wear-resistant impact-resistant self-protected surfacing-welding flux-cored wire

A self-protecting, impact-resistant technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., which can solve problems such as increased cost, low repair efficiency, and low electrode utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

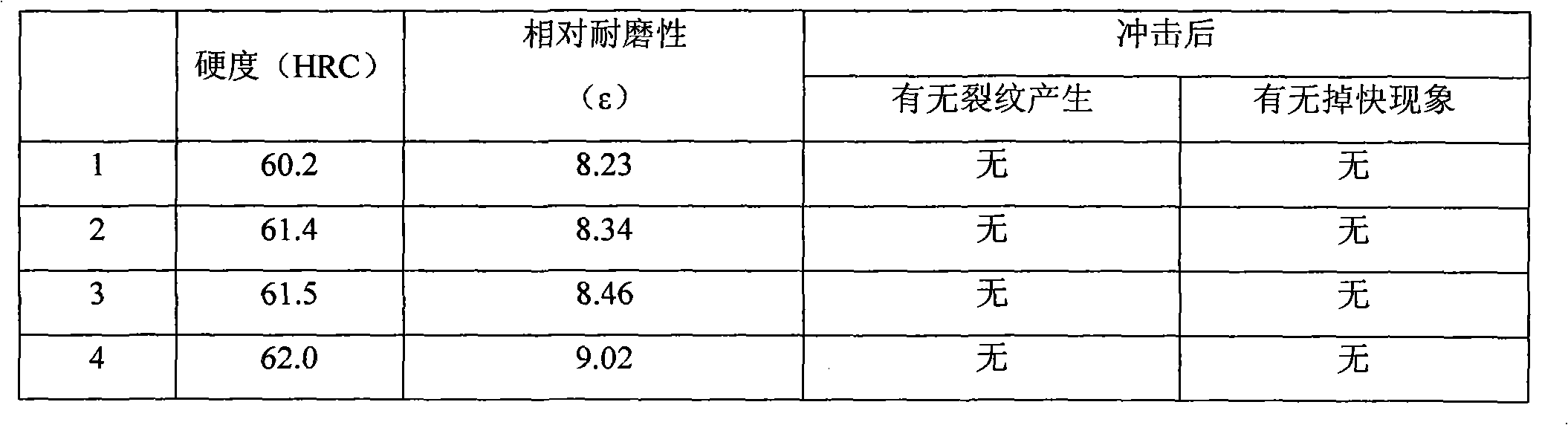

Examples

Embodiment Construction

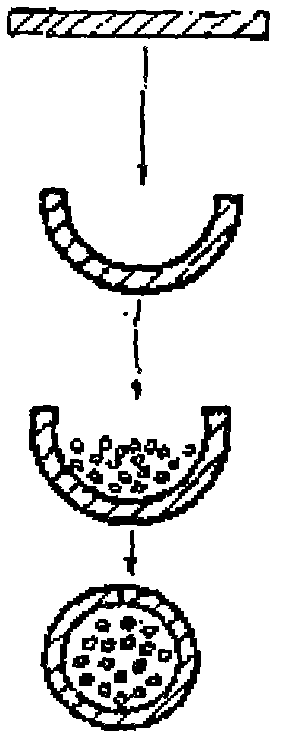

[0023] All welding wires in the examples are produced by the existing mature flux-cored wire forming machine:

[0024] 1. Select 10×0.3 (width 10mm, thickness 0.3mm) H08A cold-rolled steel strip. Roll it into a U shape first. Take 10 grams of chromium carbide, 4 grams of manganese metal, 4 grams of low-silicon ferrosilicon, 14 grams of ferromolybdenum, 35 grams of ferro-vanadium, 6 grams of ferro-titanium, 8 grams of ferro-niobium, 5 grams of sodium fluorosilicate, 6 grams of rutile, zirconium 5 grams of quartz, 3 grams of sodium fluoride. (The particle size of the powder taken is that it can pass through a 40-mesh sieve). The various powders taken are put into a powder mixer and mixed for 10 minutes, and then the mixed powder is added into a U-shaped H08A cold-rolled steel strip groove, and the filling rate is 20%. Close the U-shaped groove so that the powder is wrapped in it. Then make it pass through drawing dies with diameters of 2.8mm, 2.4mm, 2.0mm, 1.6mm, 1.4mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com