Granulation binder of compound fertilizer and application method thereof

A technology of binder and compound fertilizer, applied in fertilizer mixture, application, fertilization device and other directions, can solve the problems of not conforming to the low-carbon development trend of compound fertilizer, poor fertilizer granulation effect, high production cost, and achieve particle strength The effect of enlargement, convenient granulation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0035] A method for making and using a compound fertilizer granulation binder, comprising the following steps:

[0036] a. Adhesive production: Dissolve 18-water industrial aluminum sulfate in a solution with a water ratio of 5%; add sodium silicate to a solution with a ratio of 5%.

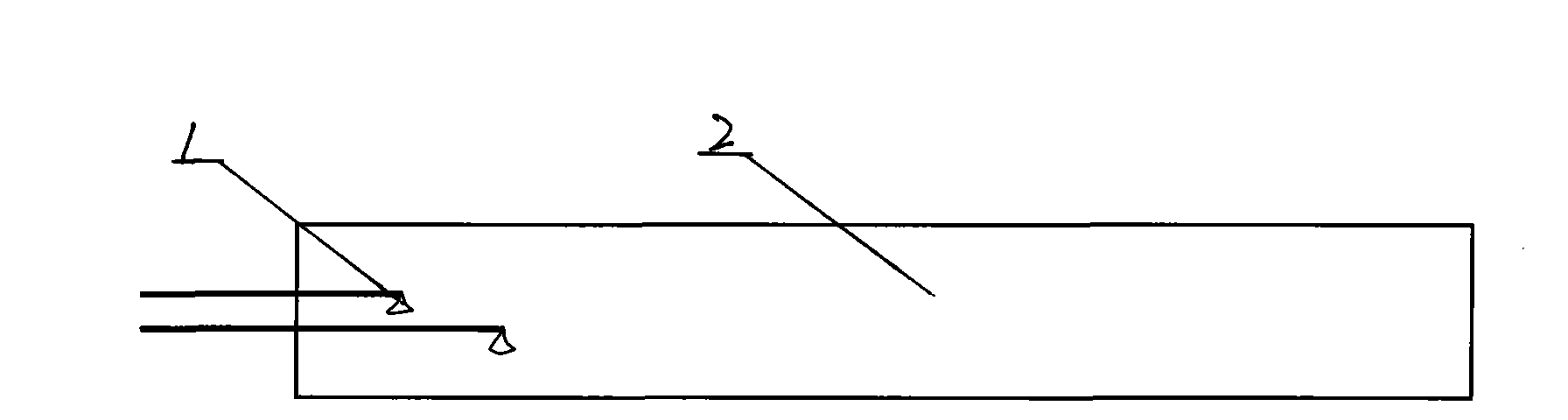

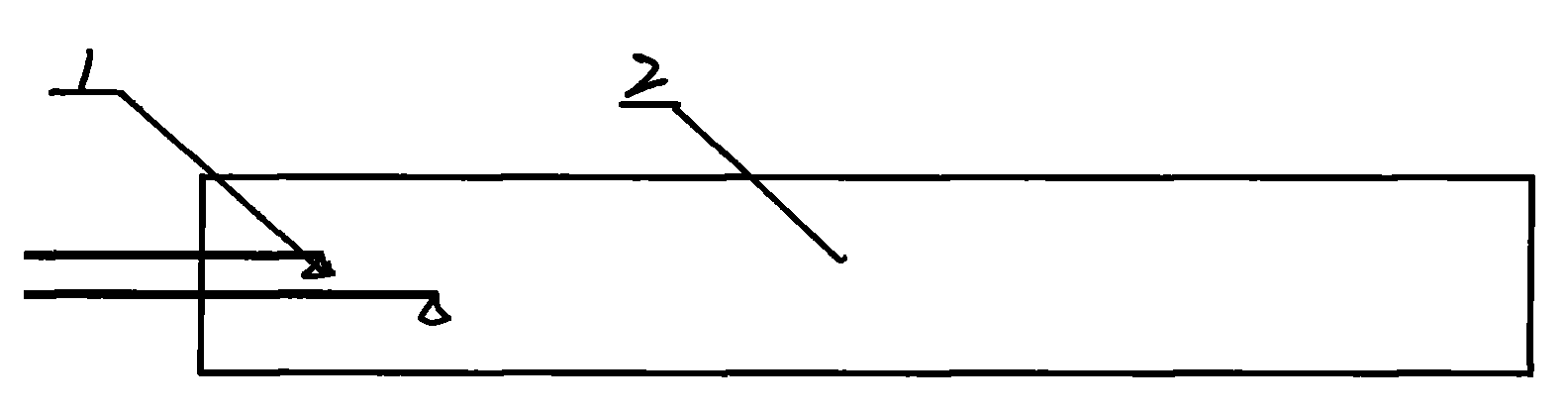

[0037] b. Adhesive nozzle setting: Spray the two solutions of aluminum sulfate and sodium silicate in a, choose stainless steel solid spiral nozzle, according to the attachment figure 1 A single nozzle is set up, and a plunger metering pump is used to deliver two solutions.

[0038] c, granulation: mix the compound fertilizer material (33% of urea, 33% of monoammonium phosphate, 12% of potassium chloride, 12% of ammonium chloride, 5% of ammonium bicarbonate, 5% of bentonite) with the compound fertilizer material of proportioning, with 10 tons The speed per hour is transported to the drum granulator. During the rolling process of the material, the two solutions of aluminum sulfate and sodium sili...

specific Embodiment approach 2

[0042] A method for making and using a compound fertilizer granulation binder, comprising the following steps:

[0043] a. Adhesive production: Dissolve 18 water industrial aluminum sulfate in a solution with a ratio of 10% to water; prepare a solution with a ratio of sodium silicate to 10%.

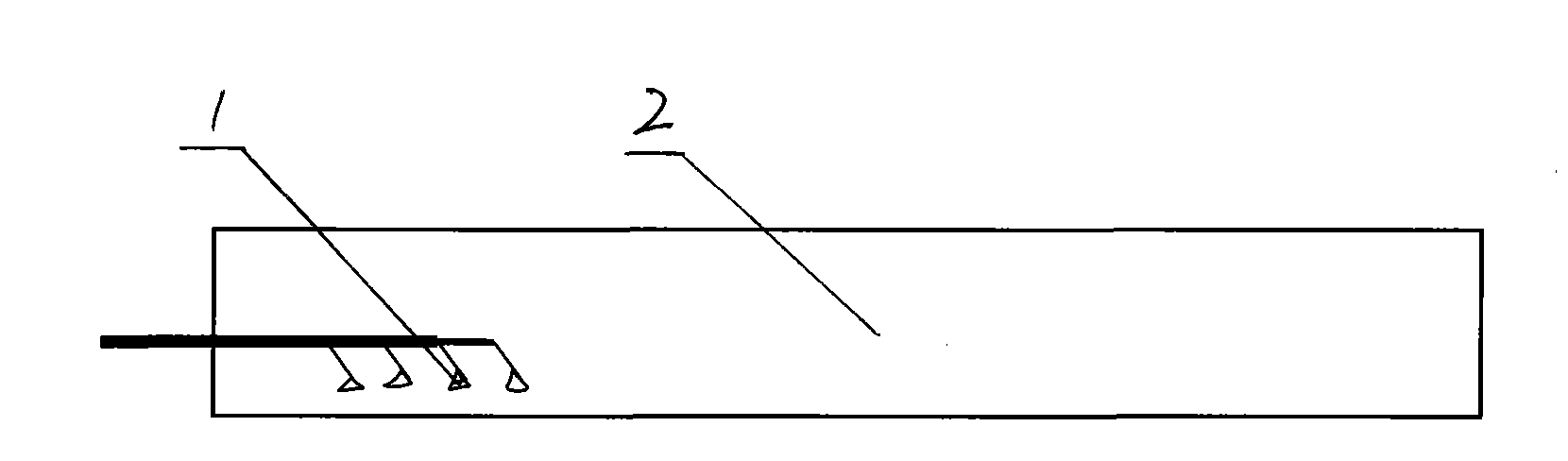

[0044] b. Adhesive nozzle setting: Spray the two solutions of aluminum sulfate and sodium silicate in a, choose stainless steel solid spiral nozzle, press the attached figure 2 Two sets of spray heads spaced apart from each other are adopted, and two kinds of adhesive solutions are metered and delivered by plunger metering pumps.

[0045] C, granulation: the compound fertilizer material (urea 60%, potassium chloride 11%, ammonium sulfate 21%, bentonite 8%) that proportioning is good, is delivered to drum granulator with the speed of 10 tons / hour, in During the rolling process of the material, two solutions of aluminum sulfate and sodium silicate are uniformly sprayed in proportion for ...

specific Embodiment approach 3

[0049] A method for making and using a compound fertilizer granulation binder, comprising the following steps:

[0050] a. Adhesive production: Dissolve 18-water industrial aluminum sulfate in a solution with a water ratio of 5%; sodium silicate with a ratio of 10%.

[0051] b. Adhesive nozzle setting: Spray the two solutions of aluminum sulfate and sodium silicate in a, choose stainless steel solid spiral nozzle, according to the attachment figure 2 Two sets of spray heads spaced apart from each other are adopted, and two kinds of adhesive solutions are metered and delivered by plunger metering pumps.

[0052] c. Granulation: transport the compound fertilizer materials (17% urea, 43% monoammonium phosphate, 16% potassium chloride, 16% ammonium sulfate, and 8% ammonium bicarbonate) with a good ratio at a speed of 10 tons / hour To the drum granulator, during the rolling process of the material, the two solutions of aluminum sulfate and sodium silicate are evenly sprayed in pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com