Method for modifying oil product

An oil and upgrading technology, applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, biological raw materials, etc., can solve the problems of unsatisfactory oil conversion rate, high catalyst cost, ineffectiveness, etc., to increase the oil heat. quality, improve oil conversion rate, reduce viscosity and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

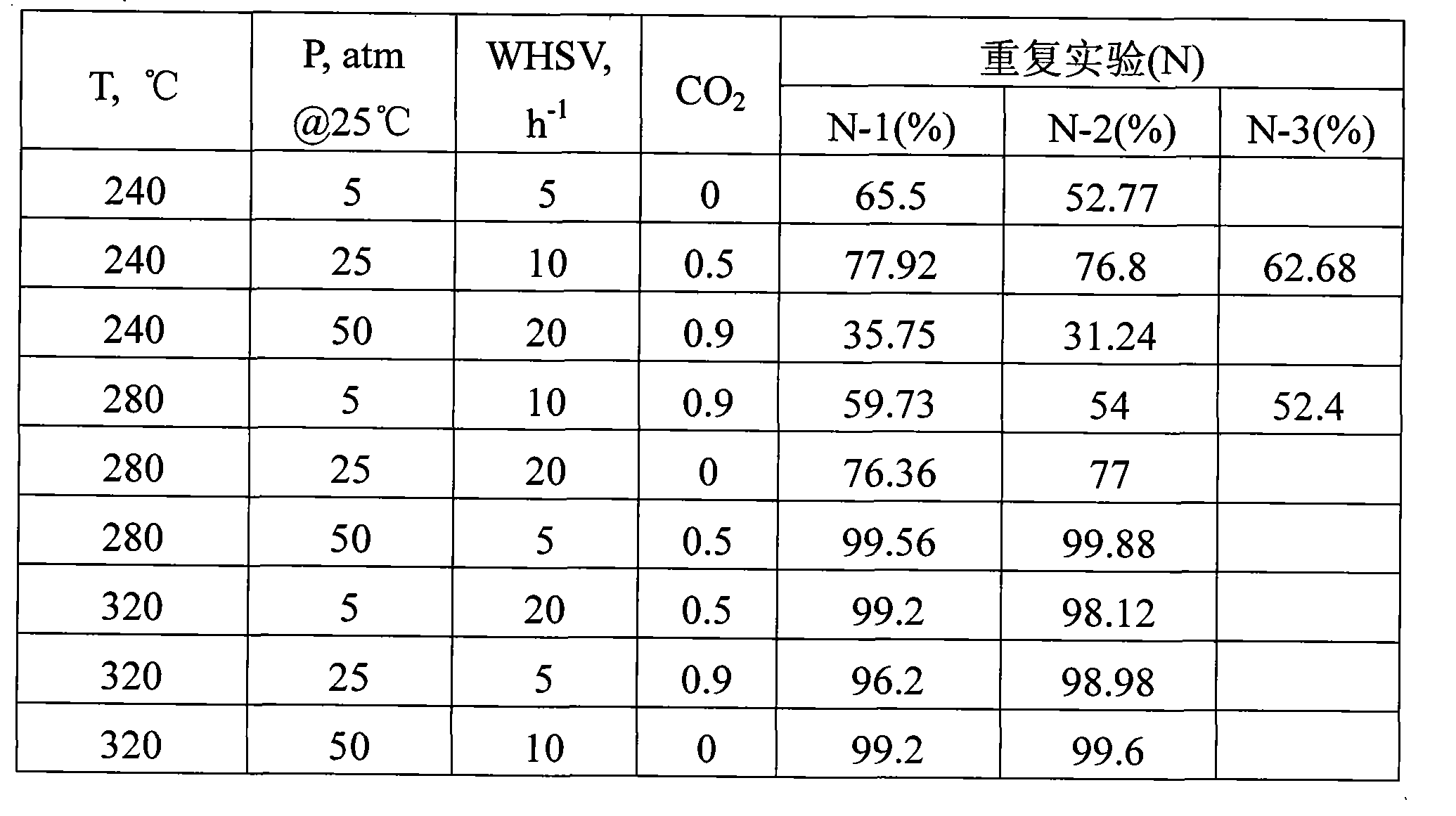

[0027] Put 5% o-methoxyphenol (Guaiacol) and 95% n-tetradecane by weight in a metal reactor, use magnetite powder as a catalyst, and carry out hydrodeoxygenation reaction of oil at a temperature of about 280°C.

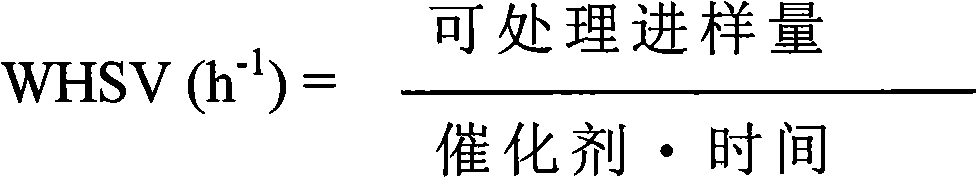

[0028] In this hydrodeoxygenation reaction, the hydrogen pressure is about 50atm (temperature is about 25°C), and the catalyst injection volume per unit time (WHSV) is about 10h -1 . Through GC-MS spectrum analysis, it can be known that the conversion rate of o-methoxyphenol is 99.97%.

[0029] Compared with the noble metal catalyst (Pd / ZrO 2 ), the cost of the magnetite powder catalyst used in the present invention is lower, and the conversion rate of o-methoxyphenol is higher.

Embodiment 2

[0031] Put 5% o-methoxyphenol (Guaiacol) and 95% n-tetradecane in a metal reactor, use ferric oxide powder as a catalyst, and carry out hydrodeoxygenation reaction of oil at a temperature of about 280°C .

[0032] In this hydrodeoxygenation reaction, the hydrogen pressure is about 50atm (temperature is about 25°C), and the catalyst injection volume per unit time (WHSV) is about 10h -1 . Through GC-MS spectrum analysis, it can be known that the conversion rate of o-methoxyphenol is 99.14%.

[0033] Compared with the noble metal catalyst (Pd / ZrO 2 ), the ferric oxide powder catalyst cost that the present invention uses is lower, but still has good o-methoxyphenol conversion rate.

Embodiment 3

[0035] Put 5% o-methoxyphenol (Guaiacol) and 95% n-tetradecane by weight in a metal reactor, use ferrous oxide powder as a catalyst, and carry out hydrodeoxygenation reaction of oil at a temperature of about 280°C.

[0036] In this hydrodeoxygenation reaction, the hydrogen pressure is about 50atm (temperature is about 25°C), and the catalyst injection volume per unit time (WHSV) is about 10h -1 . Through GC-MS spectrum analysis, it can be known that the conversion rate of o-methoxyphenol is 52.87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com