Heating device for semiconducting material hot wall epitaxy growth system

A hot-wall epitaxy and heating device technology, which is applied in the directions of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems that the heating method cannot meet the use requirements, the ultra-large diameter reaction chamber is not suitable, and the heating and cooling speed is slow. , to achieve the effect of mass production, long service life, and rapid heating and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

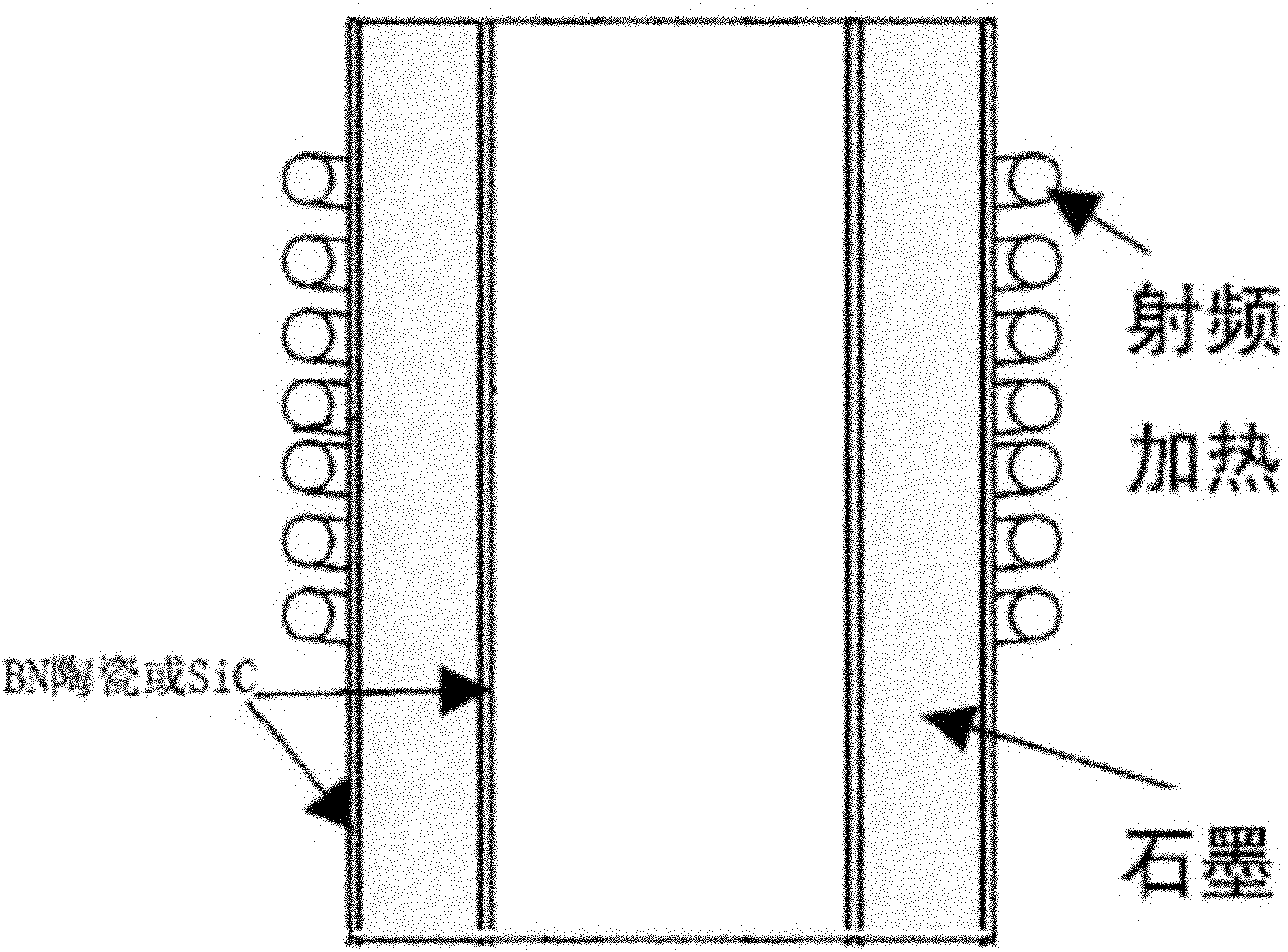

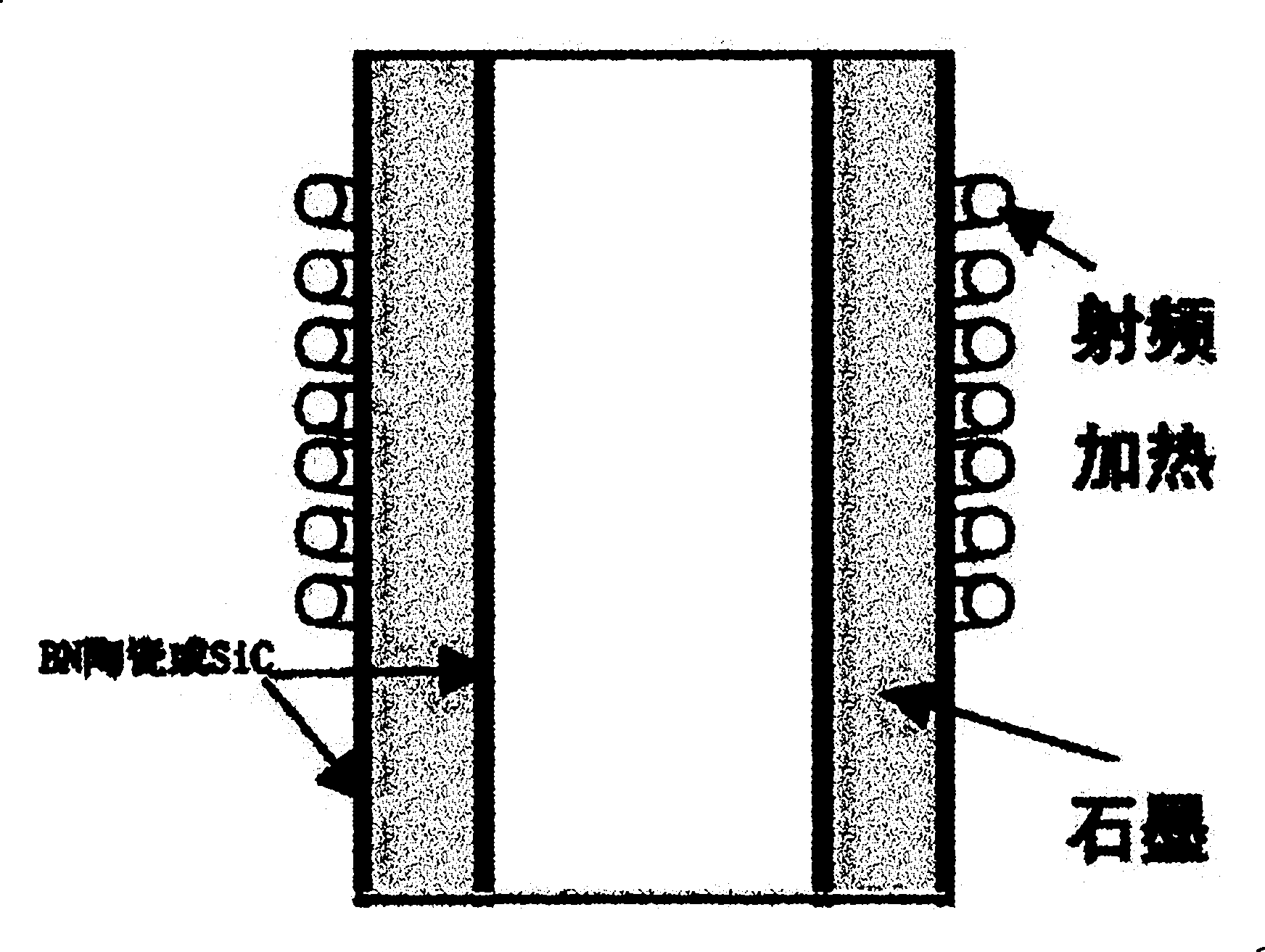

[0014] The present invention adopts radio frequency heating method, such as figure 1 As shown, the graphite sleeve is set in the induction heating coil of the radio frequency heater, and the graphite sleeve is heated by radio frequency to form a hot wall environment. The reaction chamber of the semiconductor growth system is set in the graphite sleeve, and the reaction chamber is a graphite support. The grown semiconductor material sample is placed on a graphite support. The principle of radio frequency heating is: the inductor of the radio frequency heater is generally a hollow copper tube that inputs intermediate frequency or high frequency alternating current (1000-300000Hz or higher). Put the conductive graphite sleeve into the induction heating coil, and use the principle of electromagnetic induction heating to generate an alternating magnetic field to generate an induced current of the same frequency in the graphite, heat the graphite sleeve, and convert electrical energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com