Temperature regulation method for cooling tower

A technology for cooling towers and cooling areas, applied in the field of cooling towers in power plants, can solve problems such as loss of evaporative water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

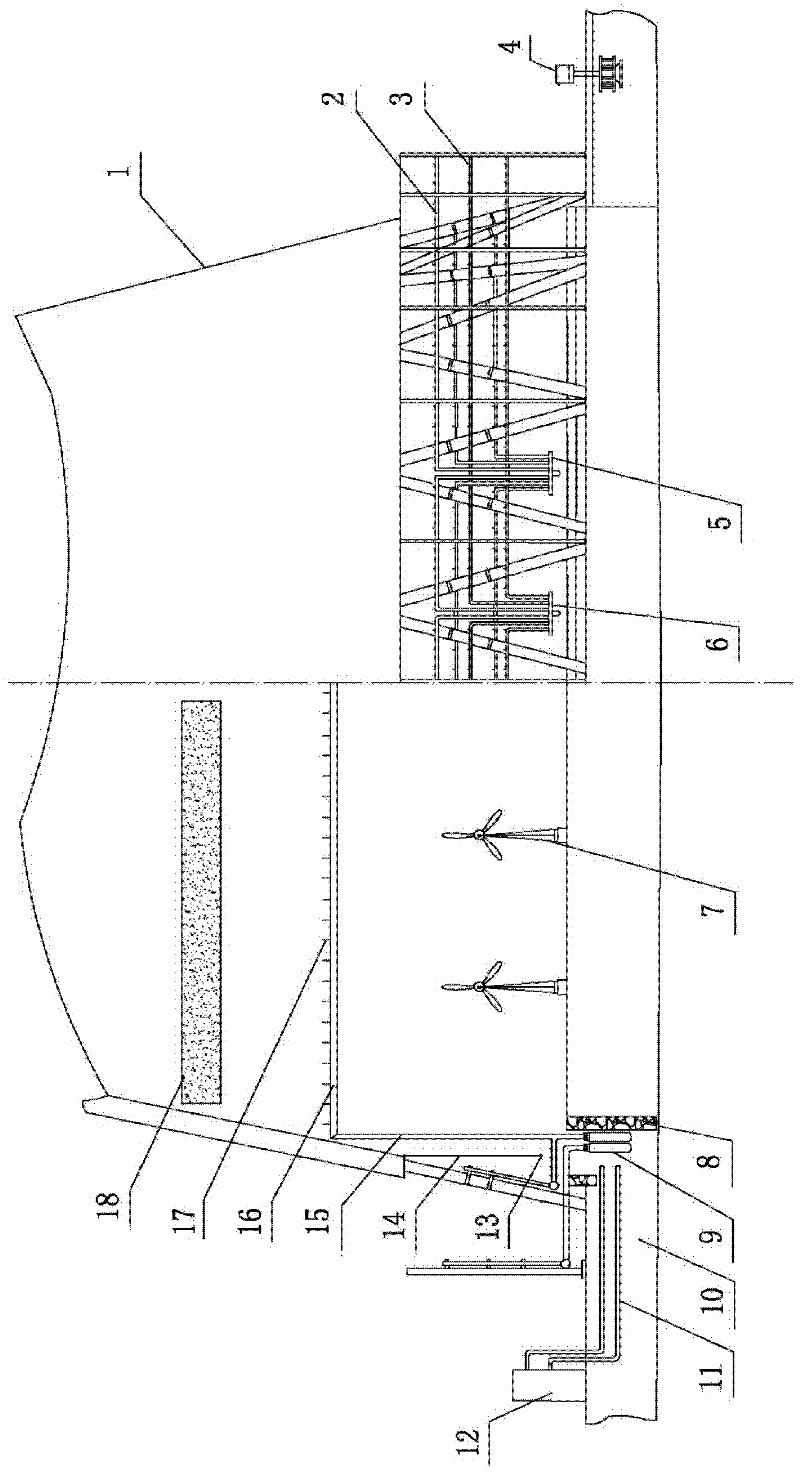

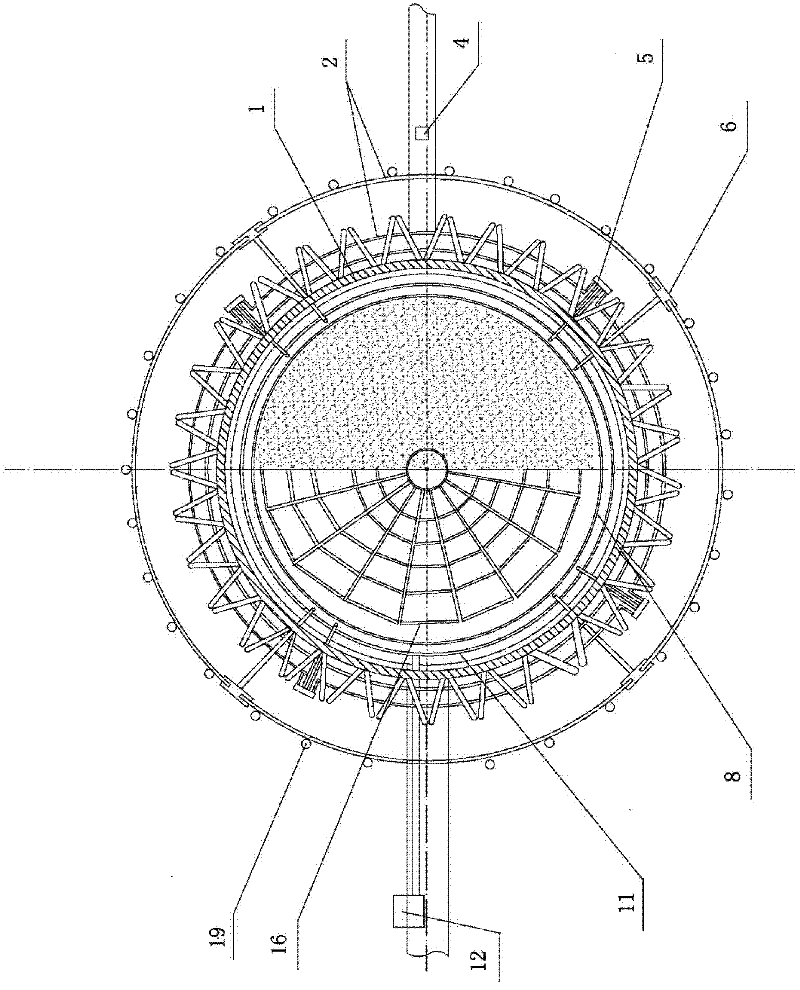

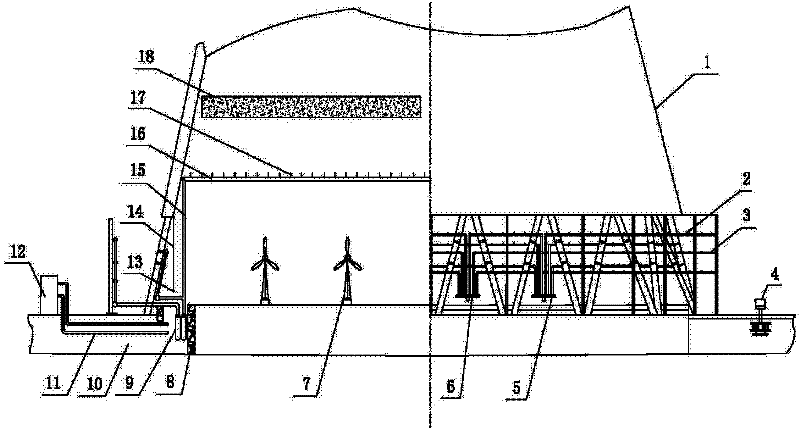

[0016] On the inner and outer sides of the air inlet of the cooling tower at the lower part of the ventilator 1, a round water pipeline 2 is installed respectively. The branch pipes of the round water pipeline 2 are distributed with nozzles 3, and the inner and outer round water pipelines respectively pass through the water separator 5, 6 are connected to the main water pipeline, the main water pipeline is connected to the storage tank via the water pump 9, and the water pipeline 2 outside the air inlet of the cooling tower is fixed by the pillar 19. The water pump 9 is a deep well submersible pump and is placed in the supplementary water source channel 10. The condensed water sprayed from the nozzle 3 is provided by the condensed water cooled by the refrigeration equipment 12 twice. The refrigeration equipment 12 adopts HBW-50(D) refrigeration equipment. An isolation wall 8 is provided in the storage pool inside the air inlet of the cooling tower to isolate the condensate wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com