Ceramic substrate for mounting luminescent element

A ceramic substrate and light-emitting element technology, which is applied in electrical components, ceramic products, applications, etc., can solve the problems of reduced reflectivity, substrate shedding, etc., and achieve the effect of improving reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Hereinafter, examples of the present invention will be specifically described, but the present invention is not limited to the following examples.

[0061] First, prepare as alumina (Al 2 o 3 ) powder with an average particle size of about 1.6 μm, silicon oxide (SiO 2 ), and at least one powder of calcium oxide (CaO) and magnesium oxide (MgO). Then, the mixed powder weighed so that the total content of each powder becomes 100% by mass is put into a tumbler together with a solvent such as water, and mixed.

[0062] Next, an acrylic resin molding binder was added thereto, and high-purity alumina balls were further mixed with a tumbler to obtain a slurry. Here, the added amount of the molding binder is set to about 4 to 8 mass % with respect to 100 mass % of the mixed powder. If it is within this range, there will be no problem with the strength and flexibility of the molded article, and there will be no problem of insufficient degreasing of the molding binder during f...

Embodiment 2

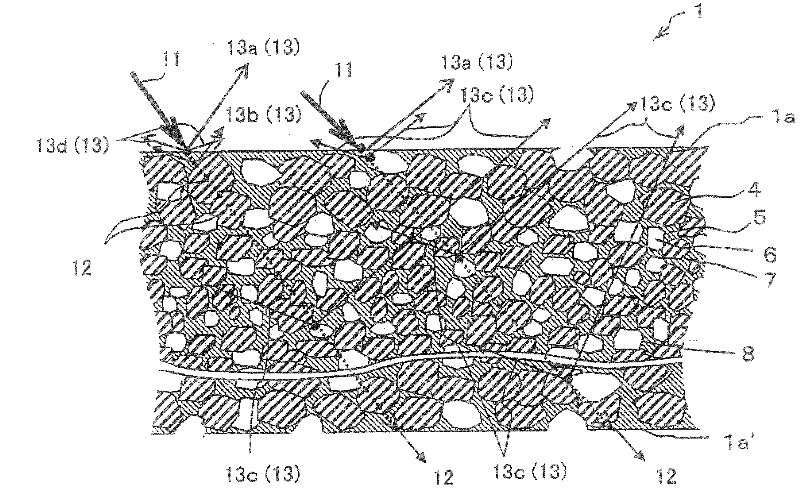

[0085] Next, the relationship with the reflectance due to the fact that the number of pores on the central portion side is larger than that on the front side of the ceramic substrate 1 for mounting a light emitting element is investigated.

[0086] First, using the same raw material as sample No. 12 produced in Example 1, a molded body was produced in the same process as in Example 1, and the rate of increase and decrease in the firing temperature and firing time shown in Table 3 Under the condition of firing, the substrate 1 is produced.

[0087]The measuring method of the porosity is the same as in Example 1. However, when measuring the number of pores on the central portion side, since the thickness of the base 1 is 0.635 mm, the base 1 is ground about 0.32 mm from the surface 1 a, and the polished surface is measured in the same manner as in Example 1. In addition, as for the reflectance, it measures here only at a wavelength of 500 nm.

[0088] Table 3 shows the obtaine...

Embodiment 3

[0093] The average pore diameter and wavelength Measurement of the reflectivity of 200-350nm.

[0094] Table 4 shows the obtained results.

[0095] Table 4

[0096]

[0097] From the results in Table 4, it can be seen that the reflectance of the sample No. 1 of the comparative example whose average pore diameter is as high as 2.02 μm has a wavelength of 350 nm or less decreases rapidly. In addition, when the average pore diameter is as small as 0.95 μm, the reflectance at a wavelength of 250 nm or less becomes low.

[0098] Sample Nos. 5, 12 and 13 of the examples of this embodiment have an average pore diameter in the range of 1.00 to 1.95 μm, reflectance to a wavelength of 300 nm is more than 80%, and a wavelength of 250 nm is more than 60%, which can significantly improve The reflectance in the ultraviolet region that becomes the problem.

[0099] Although the effect of the average pore diameter on this result is unknown, it is known that the average pore diameter is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com