Copolyester composition with thermal stability

A thermal stability, copolyester technology, applied in the field of copolyester composition, can solve the problems of insufficient melting strength of branched copolyester, slow catalytic speed, polyester thermal cracking, etc., to reduce thermal cracking phenomenon, The effect of good thermal stability, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

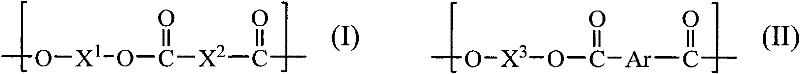

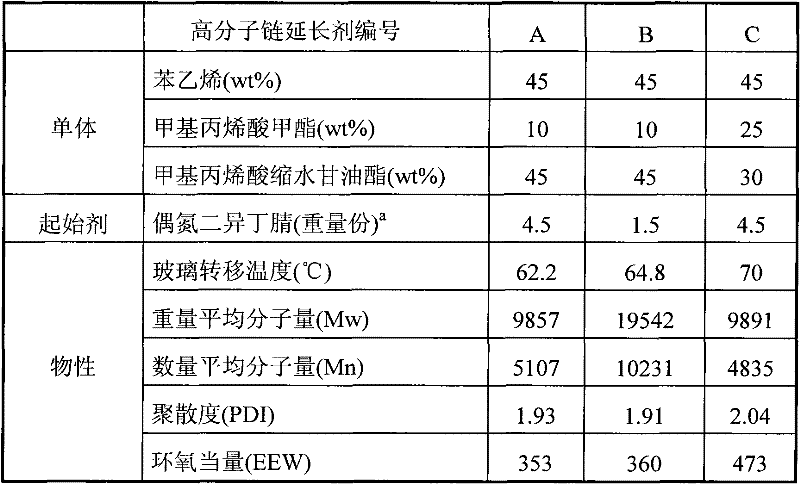

[0036] Preparation of Polymer Chain Extender Containing Epoxy Functional Group

[0037] Free radical polymerization is adopted, toluene and azobisisobutyronitrile are used as solvent and initiator respectively, and styrene, methyl methacrylate and glycidyl methacrylate are used as polymerized monomers.

[0038] The present invention synthesizes three polymer chain extenders A, B and C containing epoxy functional groups, and the ratios of monomers and initiators are listed in Table 1. First, mix the monomers according to the ratio listed in the table, then add azobisisobutyronitrile, stir until completely dissolved, then drop it into a five-liter glass reaction tank containing toluene at a fixed flow rate. The reaction temperature is controlled at 85±5°C. After two hours of reaction, the product is vacuum-dried to remove the solvent to obtain a white powder polymer chain extender containing epoxy functional groups.

[0039] According to the ASTM D 1652 standard method, the ch...

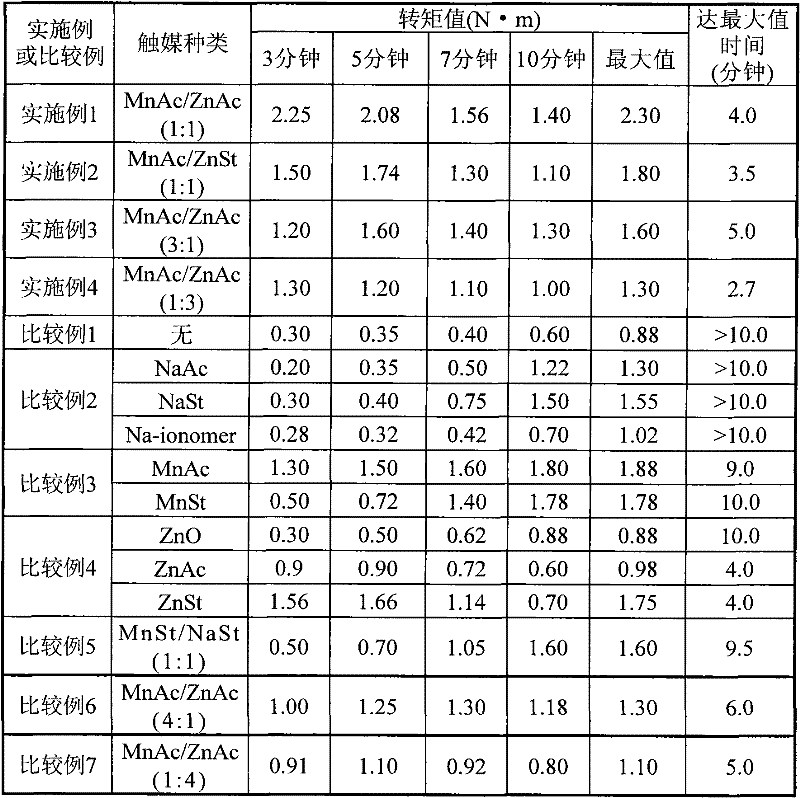

Embodiment 1~4

[0044] 100 parts by weight of butanediol adipate-terephthalate copolyester (Far Eastern New Century Company, trade name) with biodegradable properties ), 0.65 parts by weight of the obtained macromolecular chain extender A and 0.065 parts by weight of the co-catalyst (according to the following table two select catalyst type and control weight ratio, directly two kinds of catalyst mixed to obtain) after uniform mixing , using a HAAKE plastic spectrometer and controlled at 200° C. and a rotation speed of 50 rpm, melted and blended for 20 minutes to obtain the copolyester compositions of Examples 1 to 4, respectively. During the melt blending process, the torque value of the copolyester composition (in Newton·meter, hereinafter denoted as "N·m") was measured every 0.5 minutes by a plastic spectrometer, and the obtained results are shown in Table 2 below. The higher the torque value, the stronger the melt strength of the copolyester composition. That is to say, the higher the d...

Embodiment 5~7 and comparative example 8

[0052] The preparation process and conditions of Examples 5-7 and Comparative Example 8 are the same as those of Example 1, the difference is that the amounts of chain extenders and co-catalysts are changed according to the following Table 3, and finally Examples 5-7 and Comparative Example 8 are respectively obtained. copolyester composition.

[0053] Also according to the test process of Example 1, the torque values of Examples 5-7 and Comparative Example 8 were measured by a plastic spectrometer, and the gelation state was observed at the same time. The experimental results are summarized in Table 3.

[0054] Table three

[0055]

[0056] It can be seen from Table 3 that in Comparative Example 8, the amount of co-catalyst was less than 0.03 parts by weight and the amount of chain extender was less than 0.3 parts by weight, and the maximum torque value was too low, indicating that the effect of chain extension was not good and the increase in viscosity was not obvious; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com