Method and device for repairing loophole of HDPE (High Density Polyethylene) membrane at impermeable layer of landfill

A technology for landfills and anti-seepage layers, applied in protection devices, earthwork drilling, construction, etc., can solve the problems of large engineering volume and long time consumption, and achieve the effect of quick and convenient modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

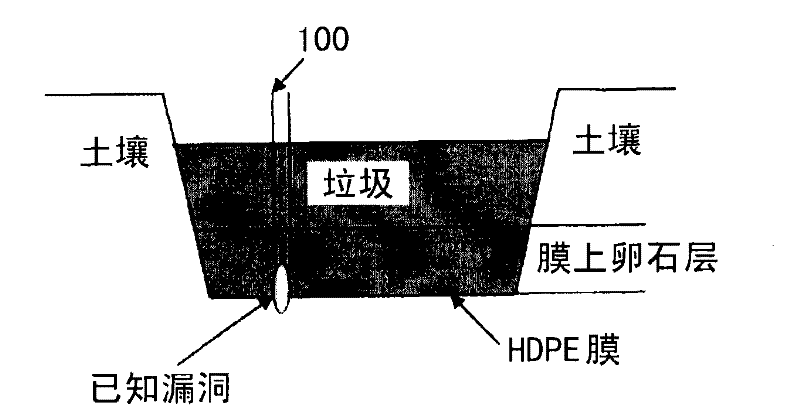

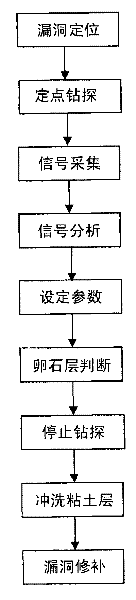

[0022] The technical principle adopted in the present invention is to judge whether the drill bit enters the pebble layer above the hole by utilizing the different characteristics of the vibration signal generated by the drill bit drilling in different medium layers. Such as figure 1 Shown is a schematic cross-sectional view of a known landfill. By solidifying the pebble layer, the high-pressure water jet is used to backwash the clay layer through the drilled hole 100 to separate the clay residue and inject cement slurry to achieve the purpose of repairing the leak. Please combine image 3 , its main steps are as follows:

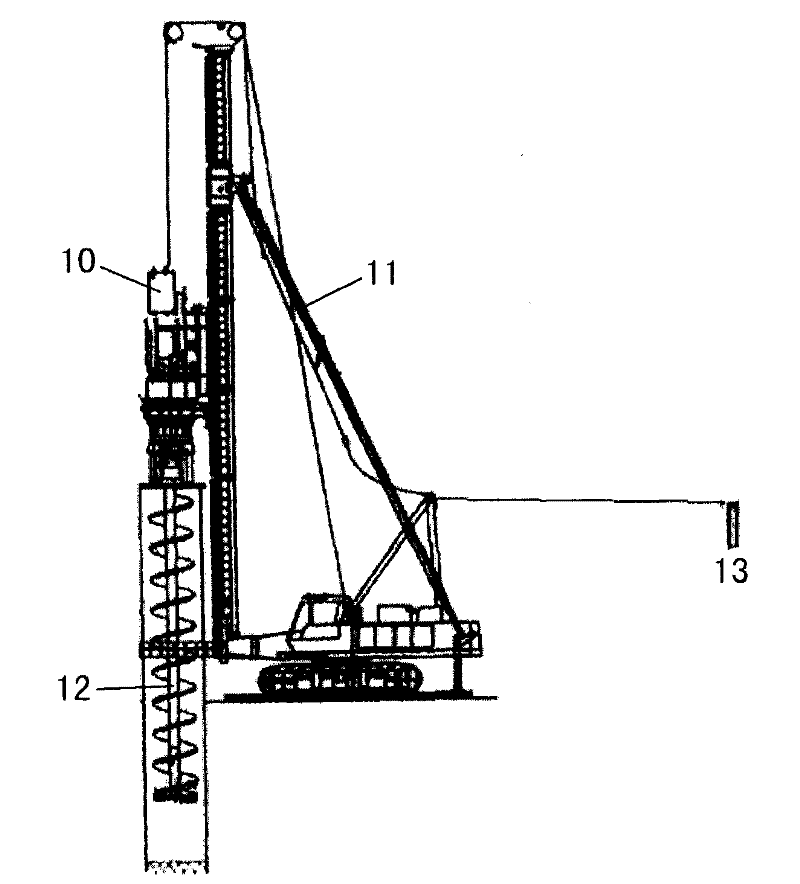

[0023] A) Drilling: Fix the engineering drilling rig and start drilling from the garbage layer in the landfill. The drill bit adopts a two-piece milling roller cone bit. In case of hard geological conditions, a diamond cone bit can also be used.

[0024] B) Data acquisition: one end of the acceleration sensor 10 (piezoelectric acceleration sensor can be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com