Magnetic slot wedge and production method thereof

A technology of magnetic slot wedge and magnetic material, applied in electromechanical devices, electrical components, manufacturing of motor generators, etc., can solve the problems of lack of mechanical strength, inability to meet long-term use, low magnetic permeability, etc., to achieve a simple production method and easy on-site Operation control, high permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

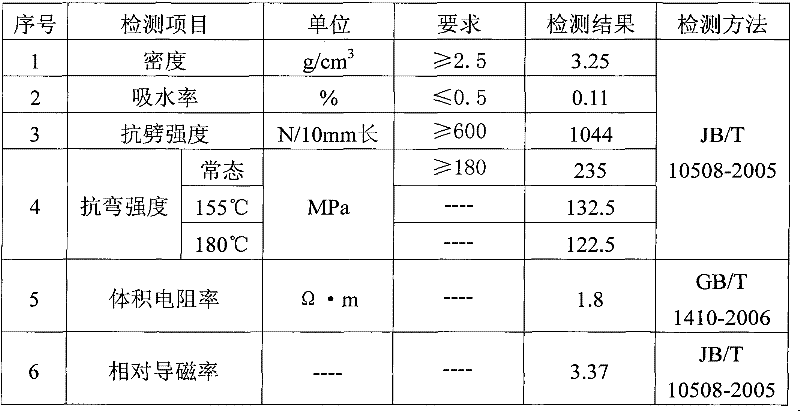

Examples

Embodiment 1

[0011] The weight percentage of each component is: 943 unsaturated polyester resin 18%, internal mold release agent (JL-125) 0.5%, tert-butyl peroxybenzoate 0.2%, dibenzoyl peroxide 0.3%, reduced iron powder 57%, 24% non-alkali glass fiber.

[0012] The production method is: (1) prepare the above-mentioned 943 unsaturated polyester resin, internal mold release agent (JL-125), tert-butyl peroxybenzoate, and dibenzoyl peroxide into an adhesive in proportion; (2) heat The temperature of the mold is raised to 150°C-200°C, and the drawing rate is 0.8-1.40r / min; (3) The alkali-free glass fiber impregnated with the adhesive is pultruded through the mold, and the thickness and width of the formed slot wedge are checked with a caliper with a watch. The thickness is 2-6mm (can be adjusted according to user requirements), the width is 4.5-28mm (can be adjusted according to user requirements), and recorded in the production record; (4) Cut the cooled slot wedge according to the model size...

Embodiment 2

[0014] The weight percentage of each component is: 943 unsaturated polyester resin 20%, internal mold release agent (JL-125) 1%, tert-butyl peroxybenzoate 0.5%, dibenzoyl peroxide 0.1%, reduced iron powder 54%, E-glass fiber 24.4%.

[0015] The production method is: (1) prepare the above-mentioned 943 unsaturated polyester resin, internal mold release agent (JL-125), tert-butyl peroxybenzoate, and dibenzoyl peroxide into an adhesive in proportion; (2) heat The temperature of the mold is raised to 150°C-200°C, and the drawing rate is 0.8-1.40r / min; (3) The alkali-free glass fiber impregnated with the adhesive is pultruded through the mold, and the thickness and width of the formed slot wedge are checked with a caliper with a watch. The thickness is 2-6mm (can be adjusted according to user requirements), the width is 4.5-28mm (can be adjusted according to user requirements), and recorded in the production record; (4) Cut the cooled slot wedge according to the model size; (5 ) G...

Embodiment 3

[0017] The weight percentage of each component is: 943 unsaturated polyester resin 19.4%, internal mold release agent (JL-125) 1%, tert-butyl peroxybenzoate 0.5%, dibenzoyl peroxide 0.1%, reduced iron powder 54%, E-glass fiber 25%.

[0018] The production method is: (1) prepare the above-mentioned 943 unsaturated polyester resin, internal mold release agent (JL-125), tert-butyl peroxybenzoate, and dibenzoyl peroxide into an adhesive in proportion; (2) heat The temperature of the mold is raised to 150°C-200°C, and the drawing rate is 0.8-1.40r / min; (3) The alkali-free glass fiber impregnated with the adhesive is pultruded through the mold, and the thickness and width of the formed slot wedge are checked with a caliper with a watch. The thickness is 2-6mm (can be adjusted according to user requirements), the width is 4.5-28mm (can be adjusted according to user requirements), and recorded in the production record; (4) Cut the cooled slot wedge according to the model size; (5 ) G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com