Method for producing canning chicken soup by utilizing raw meat

A technology of chicken soup and canning, which is applied in application, food preparation, food science, etc., can solve the problems of long processing time, poor taste, and high production cost, and achieve the effects of improving storage resistance, reducing production cost, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 (basic production method embodiment)

[0035] A method utilizing raw meat to produce canned chicken soup, characterized in that it is made from the following raw materials in parts by weight:

[0036] Chicken: 35 parts; Broiler chicken: 35 parts;

[0037] Water: 140 parts; Salt: 1.4 parts;

[0038] Ginger juice: 5 parts; Shallot juice: 2 parts;

[0039] White pepper powder: 0.14 parts;

[0040] It includes the following steps:

[0041] (1) Pre-treatment of raw materials: After slaughtering fresh native chickens and broilers, remove the heads and internal organs, cut them into 2-3cm 3 For large and small pieces of meat, blanch in boiling water for 3-5 minutes, then rinse with clean water and drain;

[0042] (2) Pretreatment of metal cans: put the cleaned metal cans in boiling water for 0.5h, or sterilize them with 0.01Mpa high-pressure steam for 15-20min, take them out and set aside;

[0043] (3) Add local chicken, broiler chicken, water, salt, raw gin...

Embodiment 2:( test Embodiment -1

[0045] Embodiment 2: (test example-1 can Tibetan chicken soup process optimization test)

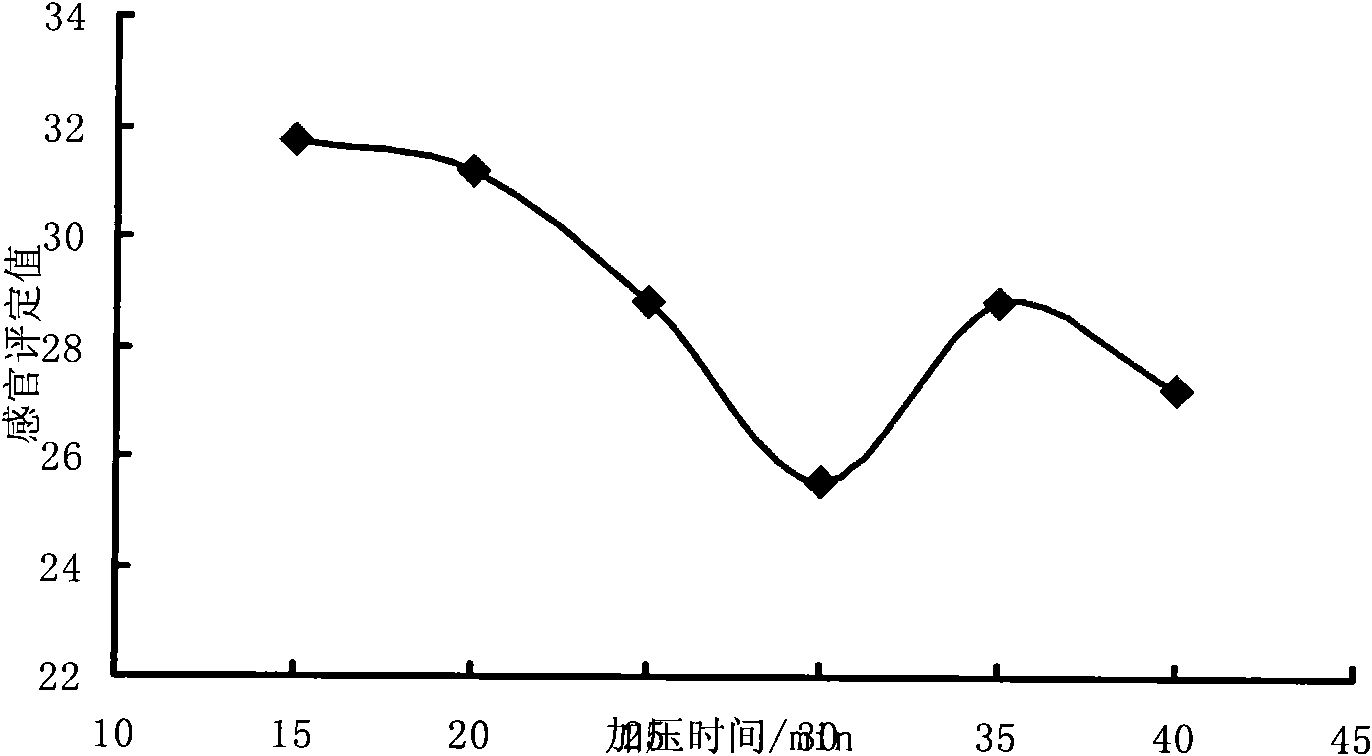

[0046] 1. Effect of pressurization time on sensory flavor of canned chicken soup

[0047] Select pressurization time 15min, 20min, 25min, 30min, 35min, 40min 6 time periods, according to the evaluation method of sensory evaluation standard of canned chicken soup in table 1, to the sensory evaluation of canned chicken soup, the result is as follows figure 1 It can be seen from the figure that the canned chicken soup produced with a pressurization time of 15 minutes has the best flavor.

[0048] Table 1 Sensory evaluation criteria for canned Tibetan chicken soup

[0049]

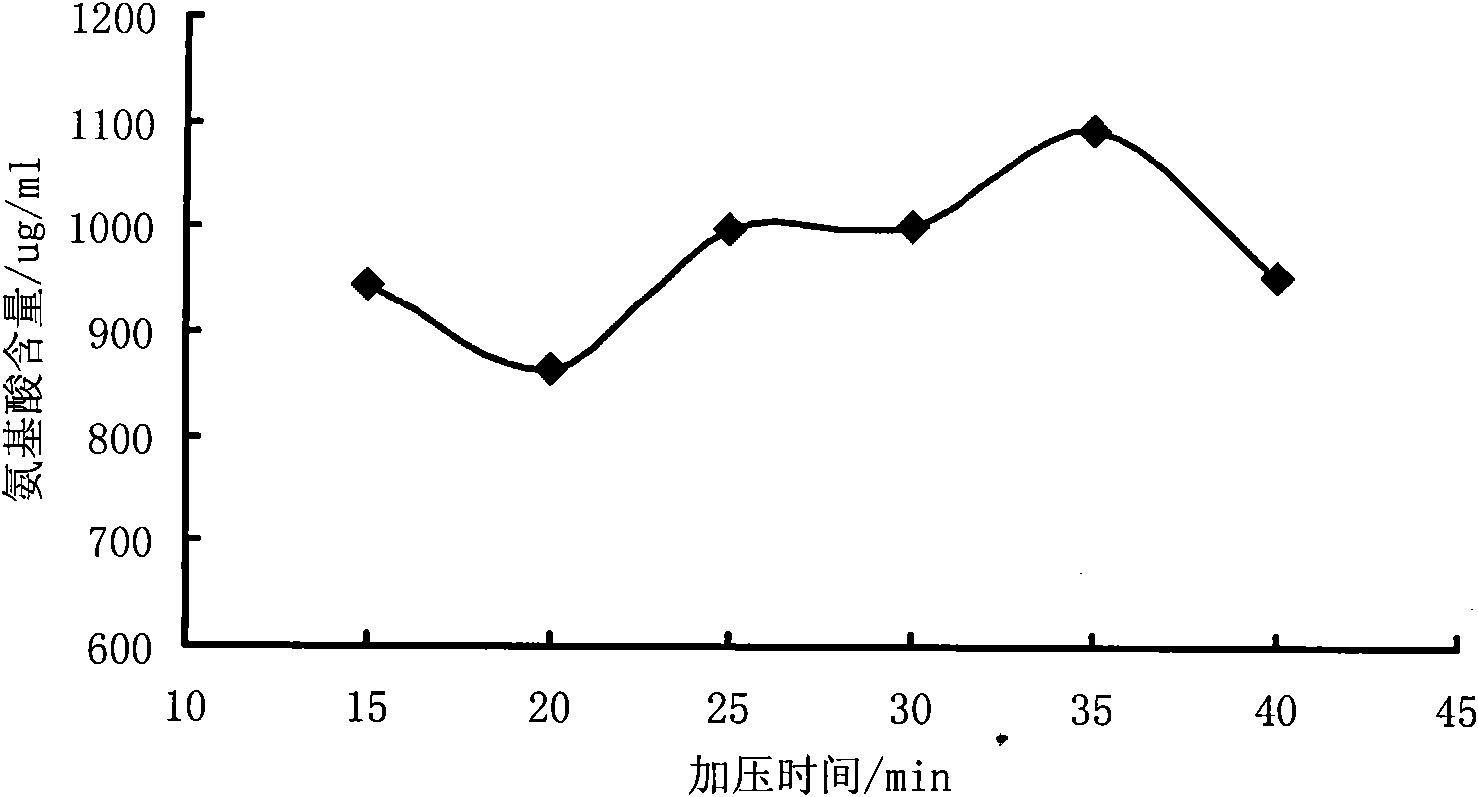

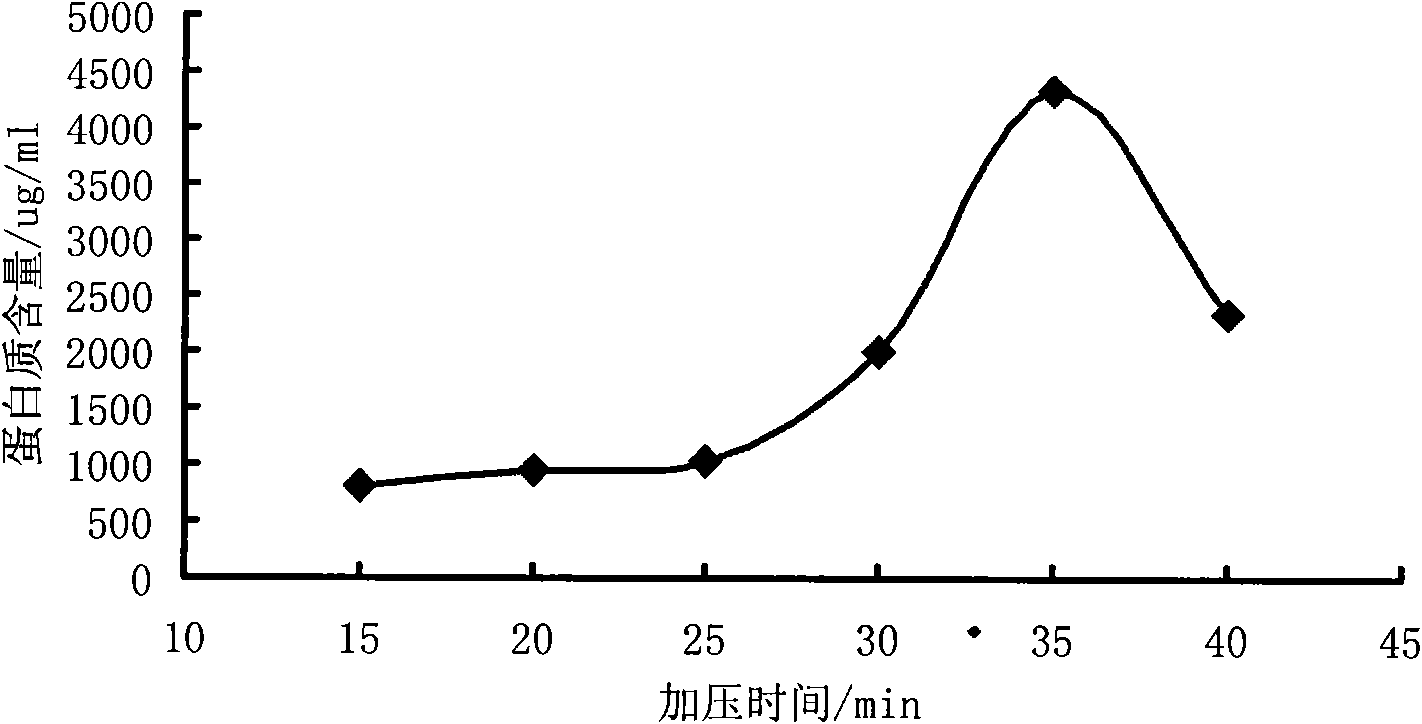

[0050] 2. Effect of pressurization time on nutrition and flavor components of canned chicken soup

[0051] Select pressurization time 15min, 20min, 25min, 30min, 35min, 6 time periods of 40min, according to the measuring method of nutrition and taste composition shown in Table 2, the free amino acid content, total s...

Embodiment 3

[0063] Embodiment 3: (the impact of test embodiment-2 pressurization time on the storage performance of canned chicken soup)

[0064] Canned chicken soup made under six different pressurization times of 15min, 20min, 25min, 30min, 35min, and 40min was selected and stored in a constant temperature incubator at 37°C to investigate the changes in nutritional components and quality during storage.

[0065] (1) Effect of pressurization time on the sensory flavor of canned chicken soup during storage

[0066] The canned chicken soup prepared under different pressures was stored in a constant temperature incubator at 37°C for 7 days, and the sensory quality was analyzed.

[0067] Sensory analysis values during storage of table 3 canned chicken soup

[0068]

[0069] It can be seen from Table 3 that the sensory quality of canned chicken soup processed at different pressurization times has different trends during the 7-day storage period. When the pressurization time is 15 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com