Trickle irrigation oxygenation method and trickle irrigation oxygenation device

A drip irrigation pipe and linkage device technology is applied in watering devices, botanical equipment and methods, climate change adaptation, etc. Scale promotion and application, the effect of reducing evaporation and salt accumulation, eliminating instability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

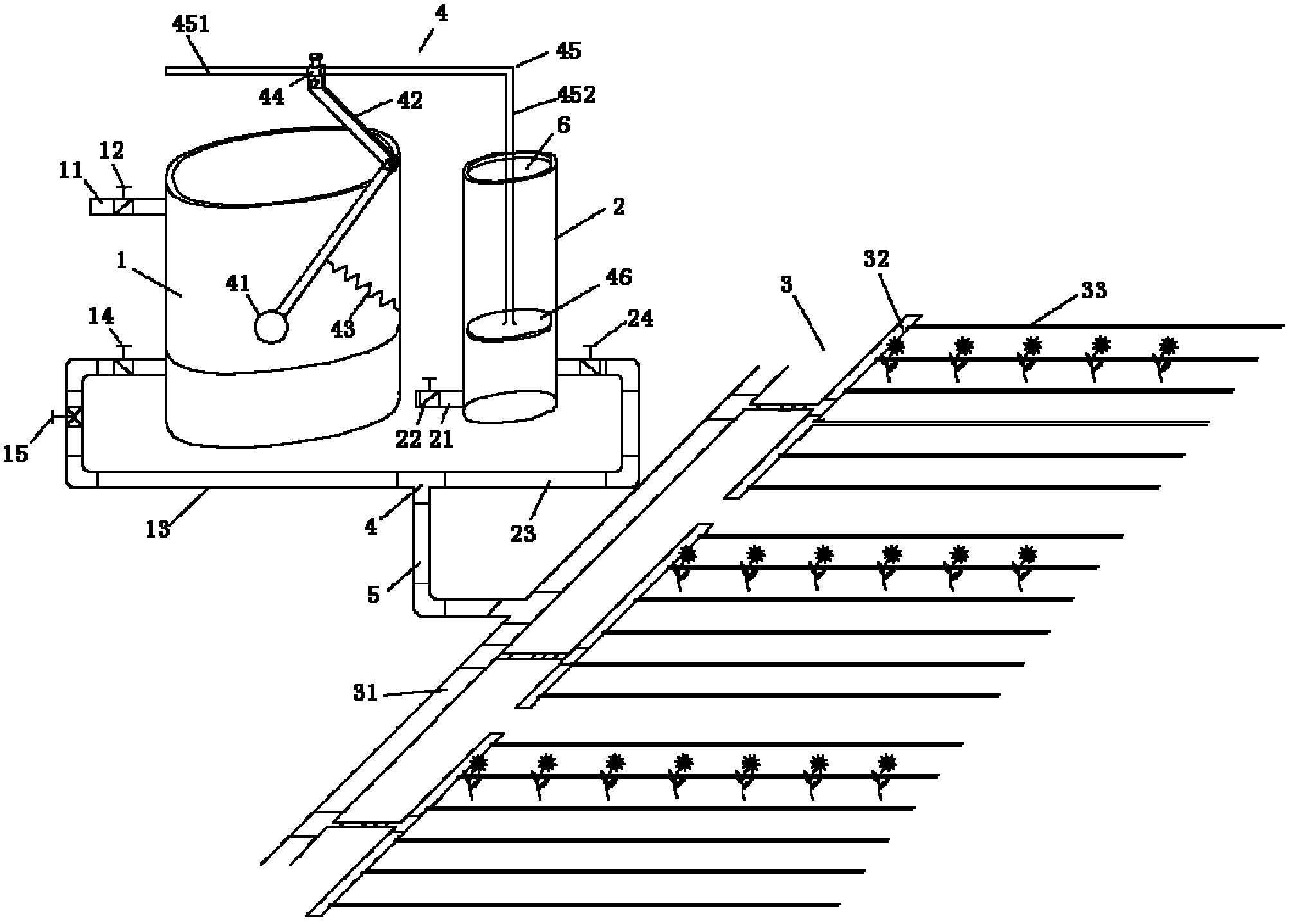

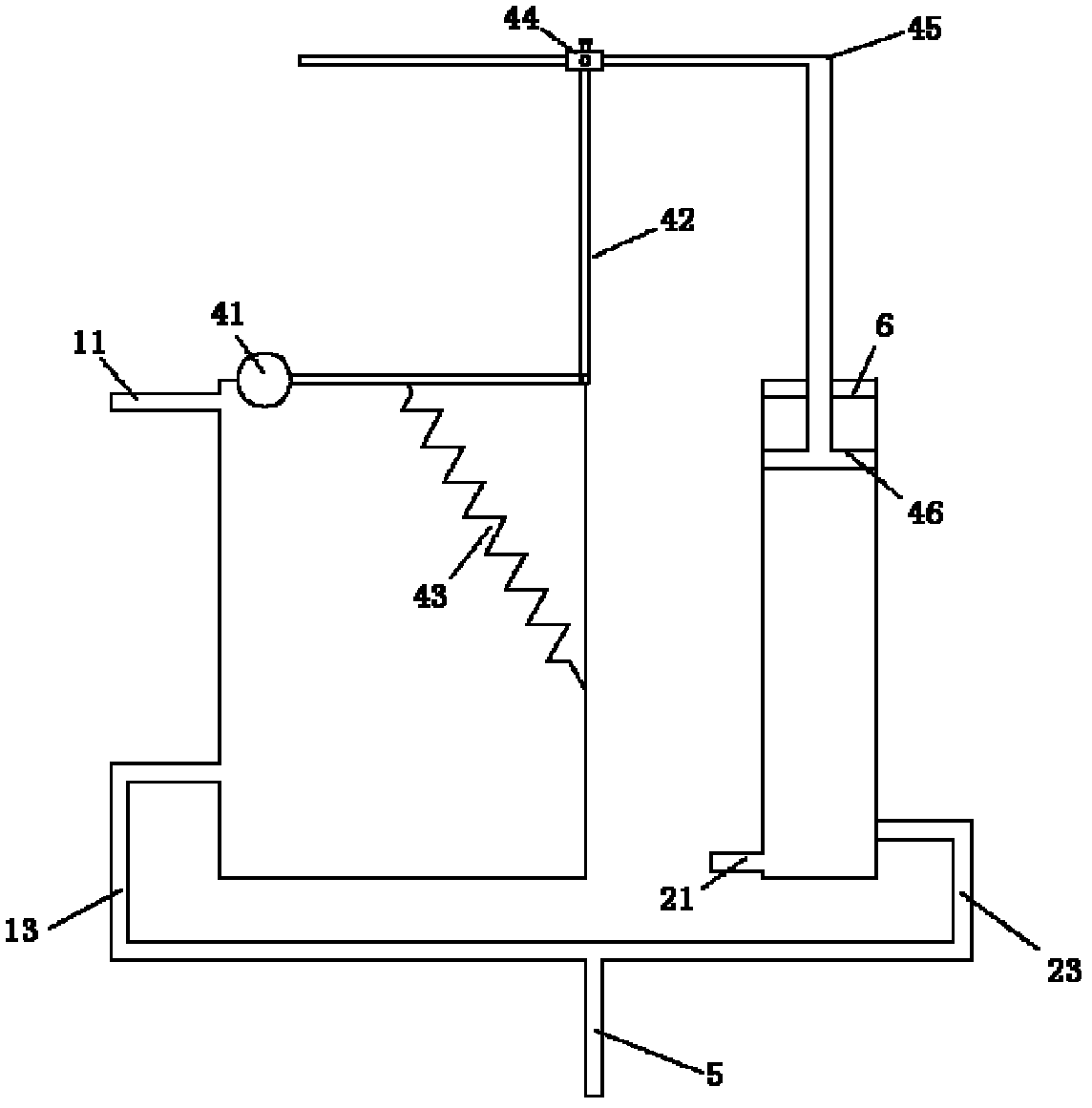

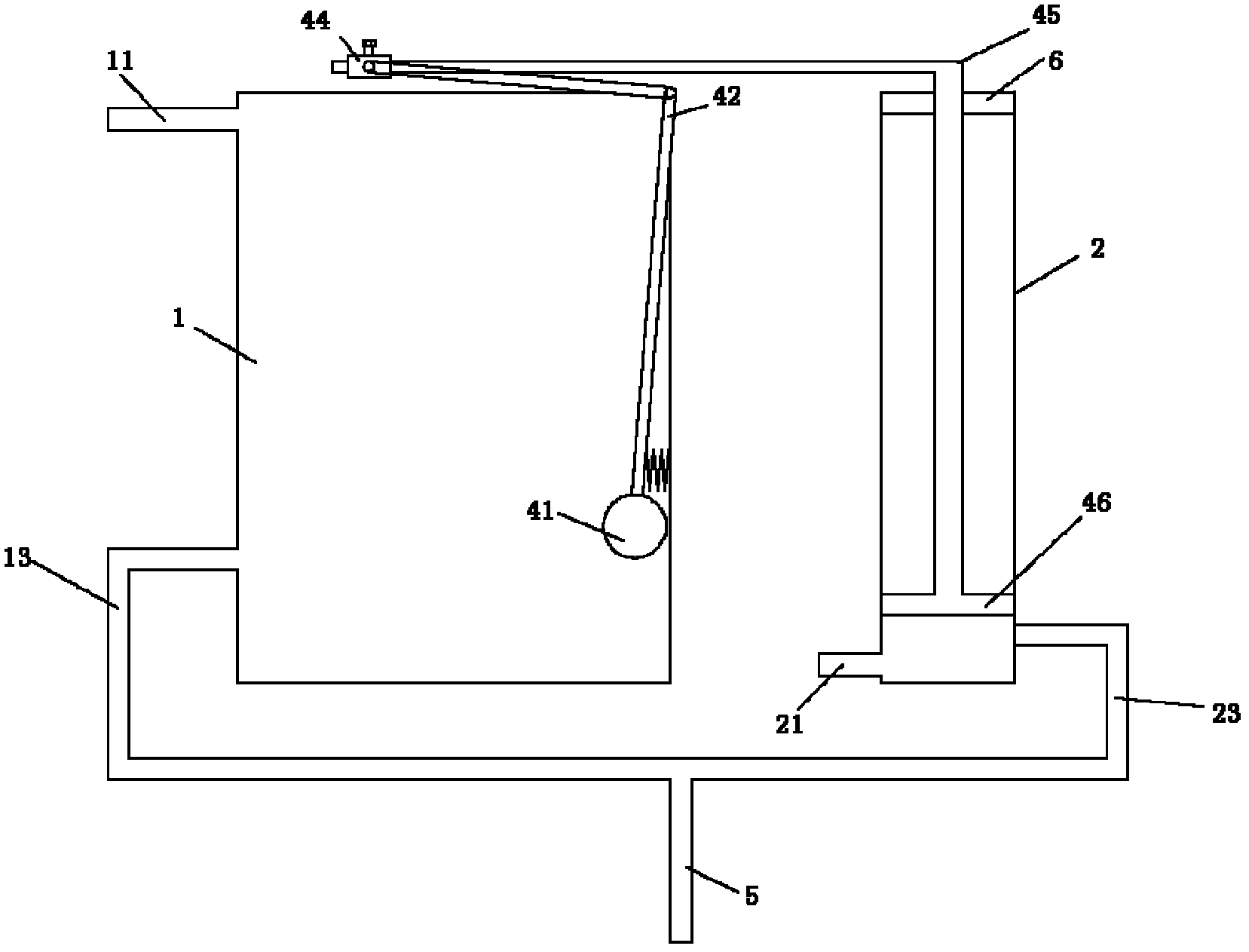

[0022] Such as figure 1 Shown, the drip irrigation oxygenation device of the present invention comprises a volume that is made of plastics and is 1m 3 Bucket 1, a volume made of plastic is 0.002m 3 Oxygen tank 2, more than one set of drip irrigation pipe network 3 and a linkage device 4.

[0023]The upper part of the water bucket 1 is provided with a water inlet, and the water inlet is connected to a water pump through a water inlet pipe 11. The water inlet pipe 11 is provided with a check valve 12, and the lower part of the water bucket 1 is provided with a water outlet pipe 13, and the water outlet pipe 13 is sequentially provided with a check valve valve 14 and a switch valve 15. A liquid inlet and a liquid outlet are respectively arranged on both sides of the lower part of the oxygenation barrel 2, and the liquid inlet extends into the oxygen-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com