Preparation method of drug-loaded water-soluble chitosan nano-particles

A technology of water-soluble chitosan and nanoparticles, which is applied in the direction of powder transportation, etc., can solve the problems affecting the cell survival rate and drug integrity, and achieve the effect of reducing the probability of particle adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

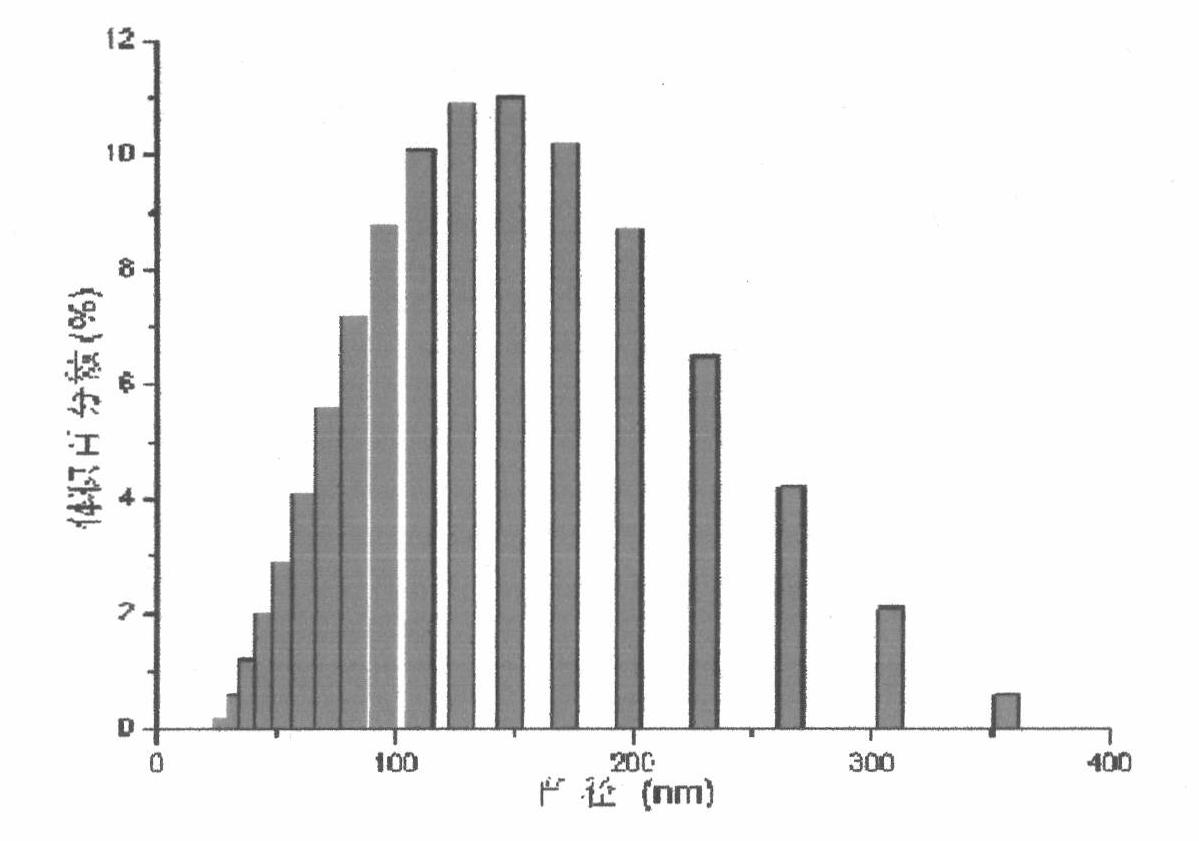

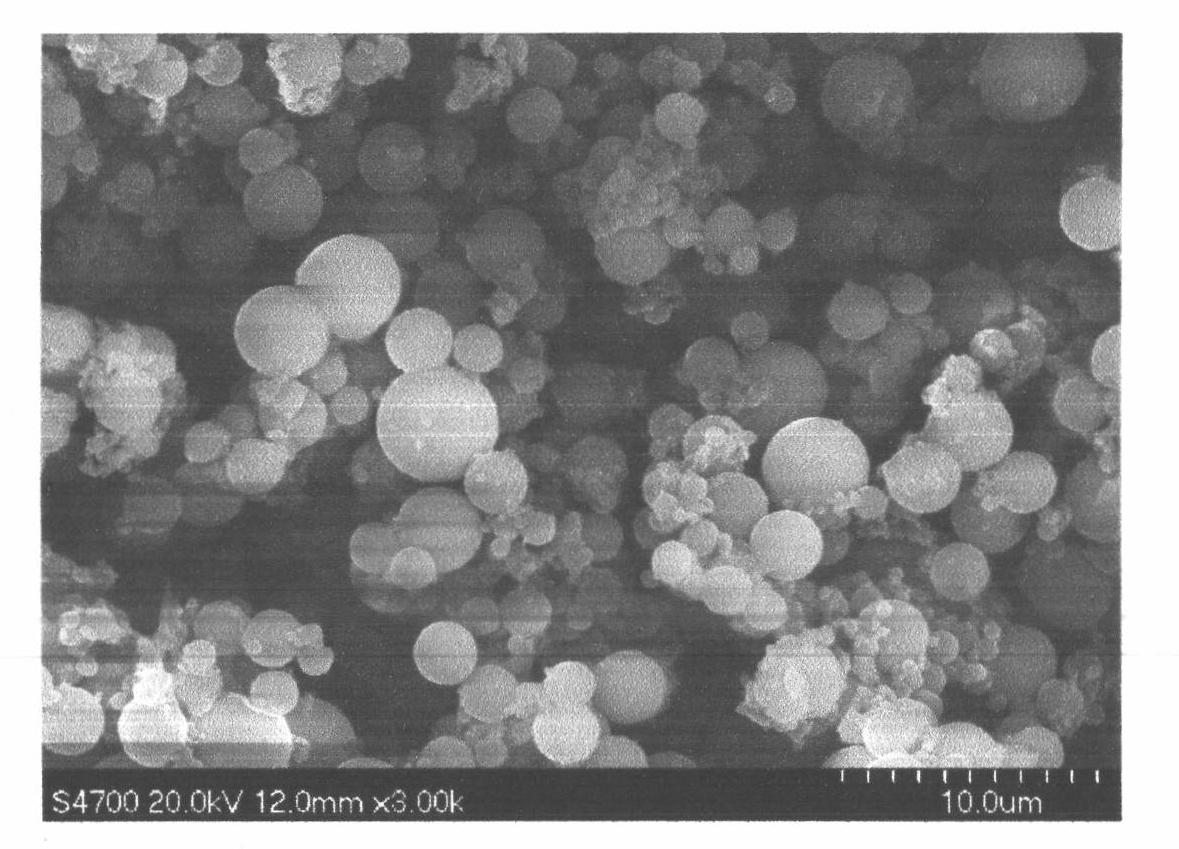

Embodiment 1

[0020] Weigh 0.2 g of water-soluble chitosan, fully dissolve it in 20 mL of deionized water, prepare a 1% (w / v) chitosan aqueous solution, and filter. Add 2mL Span80 into 80mL liquid paraffin, and stir mechanically at 2000r / min for 30min to disperse evenly. The chitosan aqueous solution was added dropwise to the oil phase, heated in a water bath to control the temperature at 40° C. and stirred for 30 min. Add 1 mL of 2% genipin solution dropwise for cross-linking, and stir rapidly at 40°C for 30 min. With 1% NaHCO 3 The pH value of the reaction system was adjusted to 4, and the reaction was performed under rapid mechanical stirring at 40° C. for 3 hours. Repeatedly wash with petroleum ether and water. Centrifuge at 4500rpm and vacuum dry at 40°C. The obtained nanoparticles have an average particle diameter of 563 nm.

Embodiment 2

[0022] Weigh 0.1 g of water-soluble chitosan, fully dissolve it in 20 mL of deionized water, prepare a 0.5% (w / v) chitosan aqueous solution, and filter. Add 2mL Span80 into 80mL liquid paraffin, and stir mechanically at 2000r / min for 30min to disperse evenly. The chitosan aqueous solution was added dropwise to the oil phase, heated in a water bath to control the temperature at 40° C. and stirred for 30 min. Add 1 mL of 2% genipin solution dropwise for cross-linking, and stir rapidly at 40°C for 30 min. With 1% NaHCO 3 The pH value of the reaction system was adjusted by the solution to 5, and the reaction was performed under rapid mechanical stirring at 40° C. for 3 h. Repeatedly wash with petroleum ether and water. Centrifuge at 4500rpm and vacuum dry at 40°C. The average particle diameter of the obtained nanoparticles is 280nm.

Embodiment 3

[0024] Weigh 0.4 g of water-soluble chitosan, fully dissolve it in 20 mL of deionized water, prepare a 2% (w / v) chitosan aqueous solution, and filter. Add 3mL Span80 into 80mL liquid paraffin, and stir mechanically at 2000r / min for 30min to disperse evenly. The chitosan aqueous solution was added dropwise to the oil phase, heated in a water bath to control the temperature at 40° C. and stirred for 30 min. Add 1 mL of 2% genipin solution dropwise for cross-linking, and stir rapidly at 40°C for 30 min. With 1% NaHCO 3 The solution adjusted the pH value of the reaction system to 6.5, and reacted with rapid mechanical stirring at 40° C. for 4 hours. Repeatedly wash with petroleum ether and water. Centrifuge at 4500rpm and vacuum dry at 40°C. The obtained nanoparticles have an average particle diameter of 249 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com