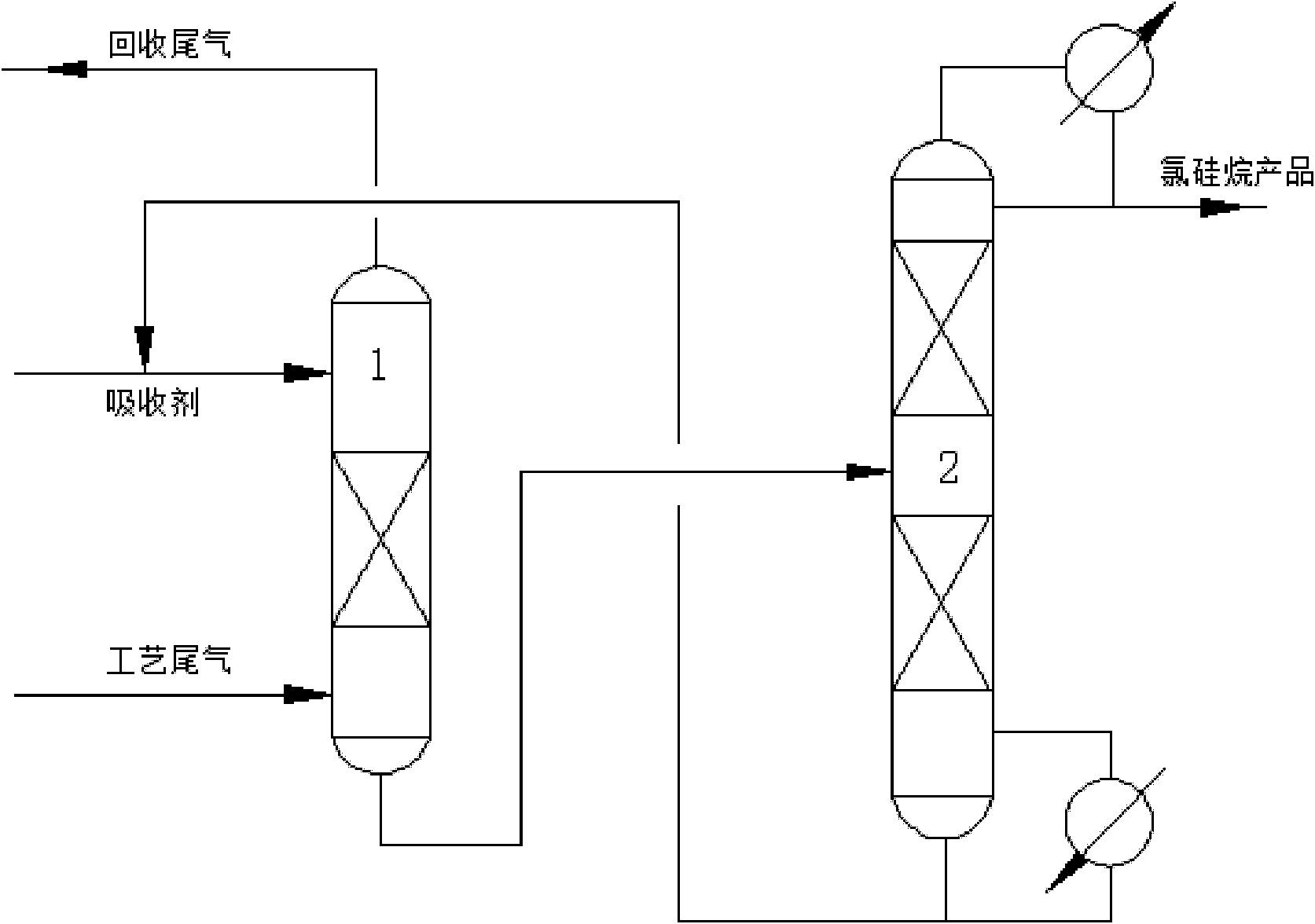

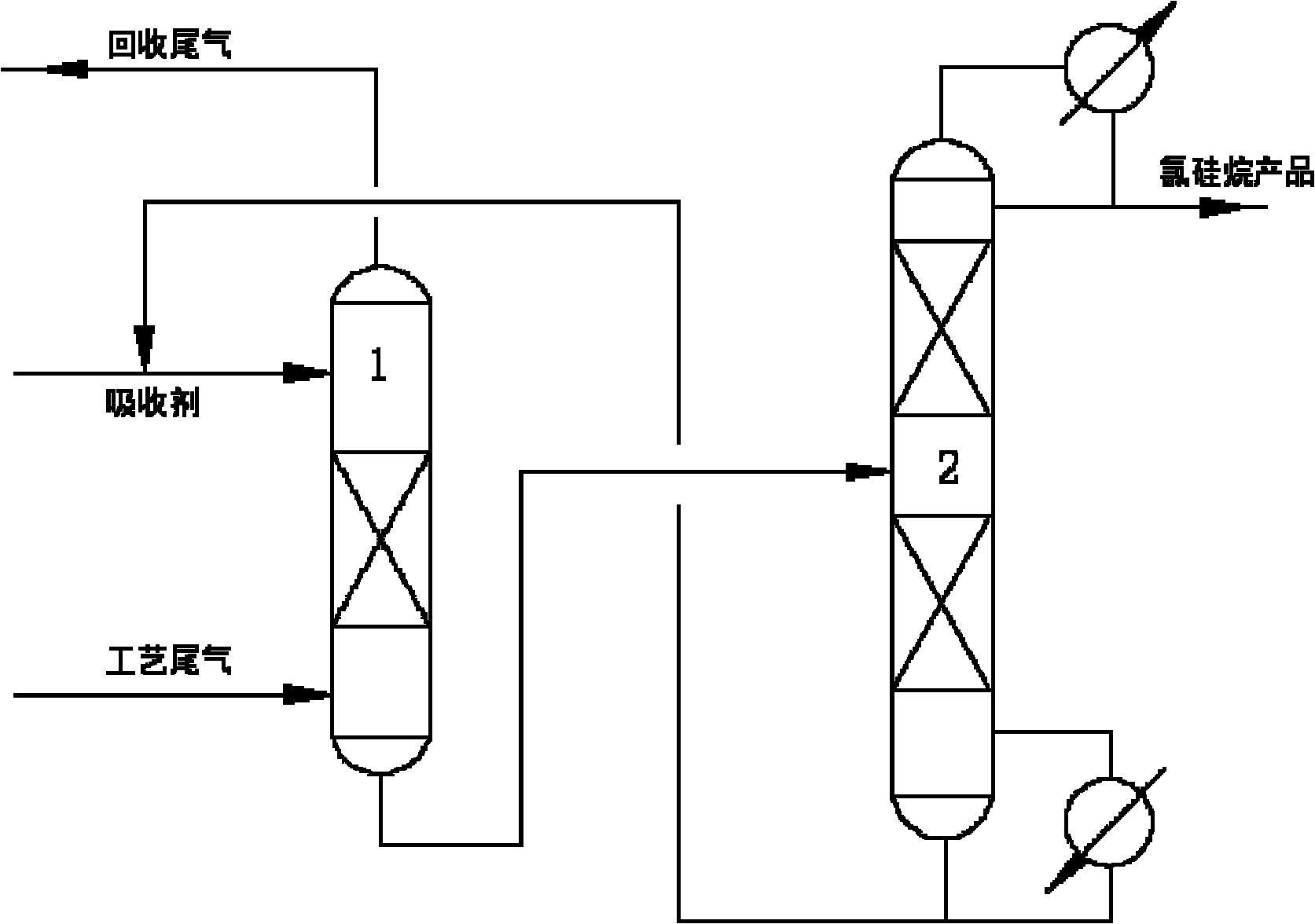

Trichlorosilane tail gas recovery device and method

A technology for recovering trichlorosilane and tail gas, which is applied in separation methods, chemical instruments and methods, halogenated silanes, etc., can solve the problems of high energy consumption, large equipment investment, incomplete tail gas recovery, etc., and achieves simple process, The effect of small equipment investment and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Trichlorosilane production process tail gas, temperature -25 ° C, pressure 0.2 MPa, composition (volume percentage, the same below) is hydrogen 80-95%, hydrogen chloride 8-15%, chlorosilane 3-7%, after buffering and metering, Enter the lower part of the absorption tower 1. Ethylbenzene is used as the absorbent, and the absorbent enters from the top of the tower at -25°C, and the absorption tower adopts a packed tower for one-stage absorption. The pressure at the top of the absorption tower is 0.19MPa, the temperature at the top of the tower is -20°C, and the temperature at the bottom of the tower is 10°C. After the absorption treatment, the tail gas is recovered from the top of the absorption tower, which is analyzed and detected by gas chromatography, and the concentrations of chlorosilanes (TCS, STC, DCS) are all zero. This stream contains only hydrogen and hydrogen chloride and can be safely returned to the hydrogen chloride synthesis furnace. The absorption liquid...

Embodiment 2

[0030] Trichlorosilane production process tail gas, after two-stage compression, the pressure is 2.0MPa, the temperature is 25°C, and the composition is 85-97% hydrogen, 2-15% hydrogen chloride, and 0.1-1% chlorosilane. After buffering and metering, it enters the absorption The lower part of Tower 1. Xylene is used as the absorbent, the absorbent enters from the top of the tower, the temperature is 25°C, and the absorption tower adopts a tray tower. The pressure at the top of the absorption tower is 1.98MPa, the temperature at the top of the tower is 20°C, and the temperature at the bottom of the tower is 55°C. After the absorption treatment, the tail gas is recovered from the top of the absorption tower, and the chlorosilanes (TCS, STC, DCS) in it are all 0 by gas chromatography. This stream contains only hydrogen and hydrogen chloride and can be safely returned to the hydrogen chloride synthesis furnace. The absorption liquid is obtained at the bottom of the absorption tow...

Embodiment 3

[0032] The source of the tail gas raw material is, in addition to the tail gas described in Example 1, there is also exhaust gas from the top of the pressurized rectification tower. The temperature of the tail gas is 0°C, the pressure is 0.4MPa, and the composition is 80-90% of hydrogen, 10-20% of hydrogen chloride, and 2-6% of chlorosilane. The tail gas enters the bottom of the absorption tower, and carbon tetrachloride and toluene are used as binary absorbents. To -10 ℃ into the top of the absorption tower. The pressure at the top of the absorption tower is 0.39MPa, the temperature at the top of the tower is -5°C, and the temperature at the bottom of the tower is 35°C. The absorption tower adopts a packed tower. The pressure at the top of the desorption tower is 0.2MPa, the temperature at the top of the tower is 66-67°C, and the temperature at the bottom of the tower is 120°C. The desorption tower adopts a plate tower. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com