Machining device and method for polishing blade profile of integrated bladed disk

A technology of integral blisks and processing methods, which is applied in the direction of metal processing equipment, electrochemical processing equipment, and the supply of processing working media, etc., can solve the problems of unstable quality, low processing efficiency, and high cost, and achieve uniform processing surface and improved Efficiency, improved surface quality and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention will be described in detail below with reference to the drawings and embodiments.

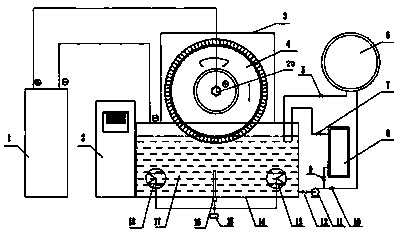

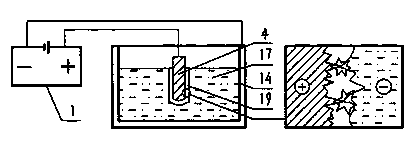

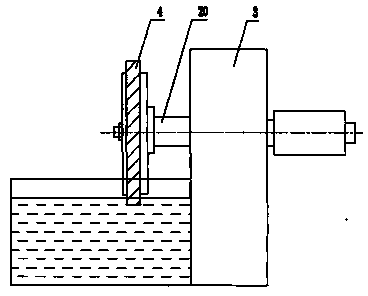

[0030] figure 1 It is a schematic diagram of a processing device for blade profile polishing in an embodiment of the present invention. figure 1 The name of the winning mark: 1 power supply, 2 controller, 3 bed, 4 integral blisk workpiece, 5 ball valve, 6 micro filter, 7 ball valve, 8 heat exchanger, 9 stop valve, 10 stop valve, 11 pump, 12 stop Return valve, 13 heater, 14 working cell, 15 temperature controller, 16 thermocouple, 17 electrolyte, 18 heater, 20 spindle.

[0031] The positive pole of the power supply 1 is connected to the main shaft 20 on the bed 3, and the blisk workpiece 4 is positioned and clamped on the main shaft 20. The main shaft 20 drives the blisk workpiece 4 to rotate at the speed N, and immers the blisk workpiece 4 in the electrolyte. In 17, the negative electrode of the power supply is connected to the working cell 14; the heaters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com