Processing technology and device of optical fiber plasma liquid

A micro-plasma and liquid treatment technology, applied in the direction of light water/sewage treatment, sterilization/microdynamic water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of complex device structure and large gas flow, and achieve High gas utilization rate, improved treatment effect, and high sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the utility model is further described.

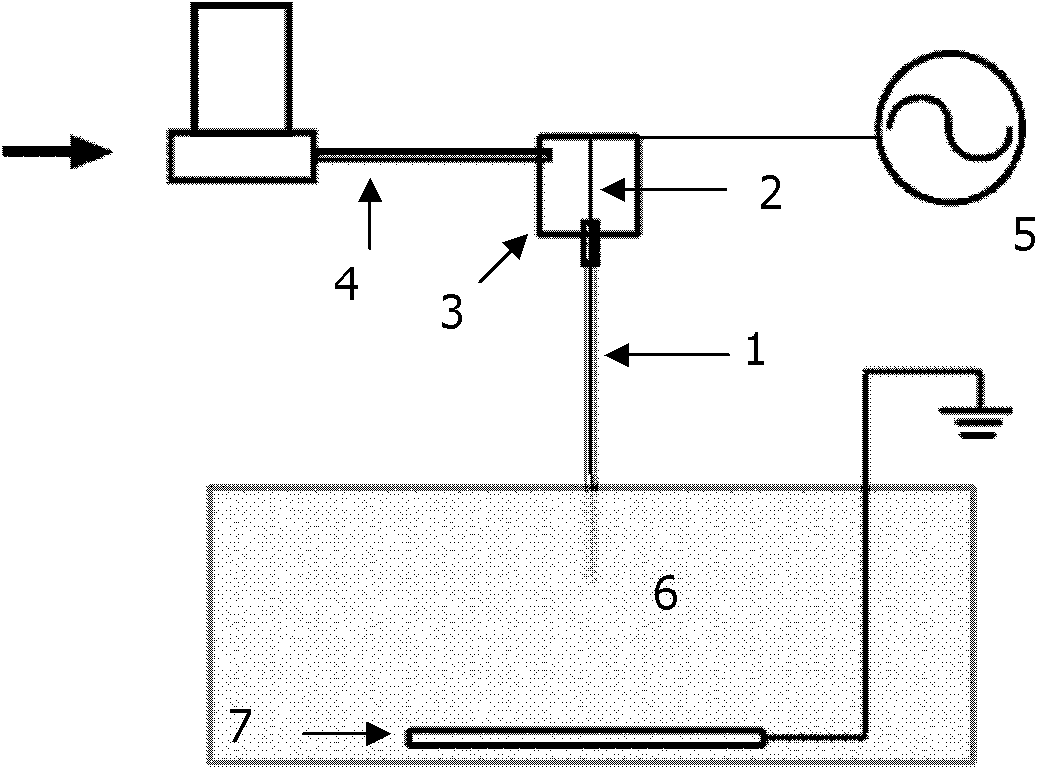

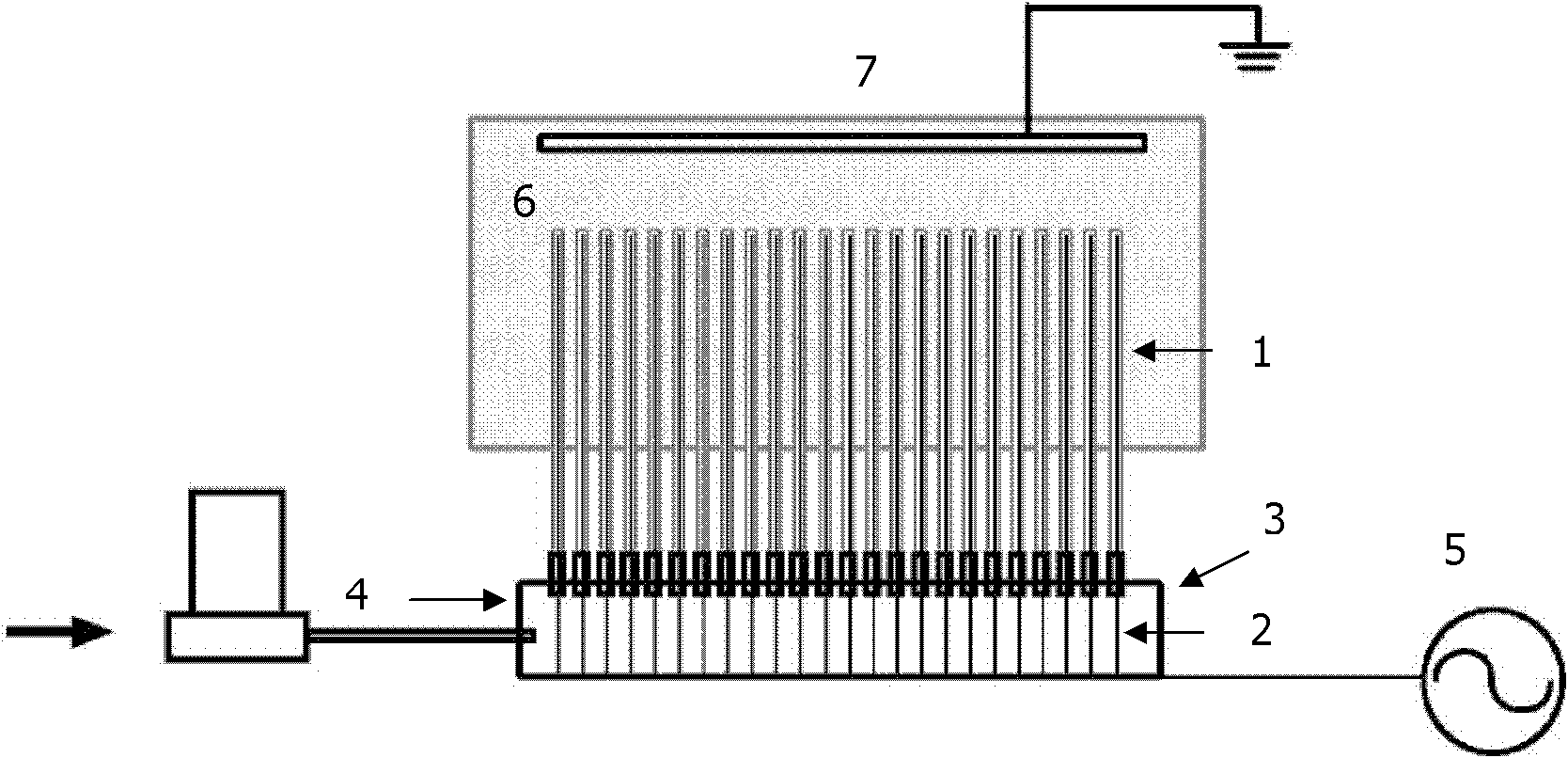

[0021] Use a single optical fiber to confine the discharge gas to realize micro-plasma generation in liquid under atmospheric pressure. The device is as follows figure 1 As shown, a microporous optical fiber 1 is used to insert a high-voltage electrode 2. One end of the microporous optical fiber 1 is inserted and communicated with the air cavity 3, and the other end together with the high-voltage electrode 2 in it is inserted into the liquid to be treated. The sample 6 is below the liquid surface and suspended above the ground electrode 7 in the liquid. The high-voltage electrode 2 is connected to an AC sine wave high-voltage power supply 5 for generating plasma, the peak-to-peak voltage of which is above 14KV, and the frequency is within the range of 5KHZ-15KHZ. Before discharge, the discharge gas is passed through the gas mass flow controller from the gas inlet 4 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com