Preparation method of magnetic thermosensitive core-shell composite microsphere

A technology of composite microspheres and temperature-sensitive cores, which is applied in the direction of magnetism of organic materials/organic magnetic materials, can solve the problems of complicated operation in the preparation process of monodisperse magnetic temperature-sensitive composite microspheres, and achieve the effect of simple operation in the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

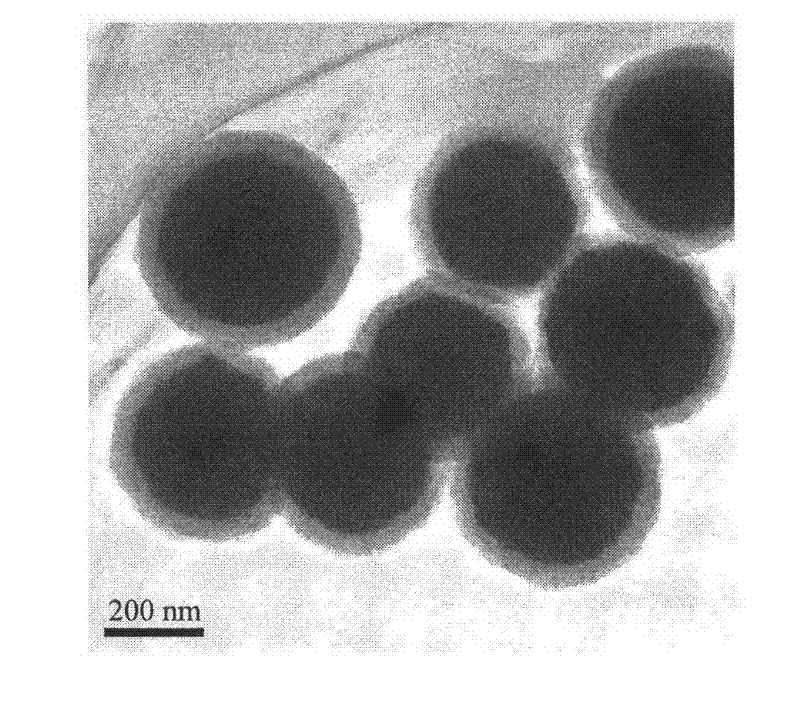

[0017] Embodiment 1: In the 50mL reactor that is equipped with condenser tube, add 30g distilled water, 1g methyl alcohol and 1g ethanol; With 0.005g Fe 3 o 4 Add the microspheres into a 50mL reactor and sonicate for 30min; add 0.003g of MBA (methylenebisacrylamide) and 0.03g of NIPAM (N-isopropylacrylamide) monomer mixture and 0.001g of KPS (potassium persulfate) Add to the reactor, shake to dissolve; pass N 2 After 25 minutes, gradually raise the temperature to 65°C, and polymerize for 10 hours; magnetically separate the obtained product, pour off the supernatant, add distilled water for ultrasonic dispersion, and then magnetically separate; repeat this process several times to remove excess monomer and polymerization thing. After vacuum drying at room temperature, the magnetic thermosensitive core-shell P(NIPAM-MBA) / Fe 3 o 4 Microspheres.

[0018] After testing, the obtained magnetic temperature-sensitive core-shell P(NIPAM-MBA) / Fe 3 o 4 The particle size of the mic...

Embodiment 2

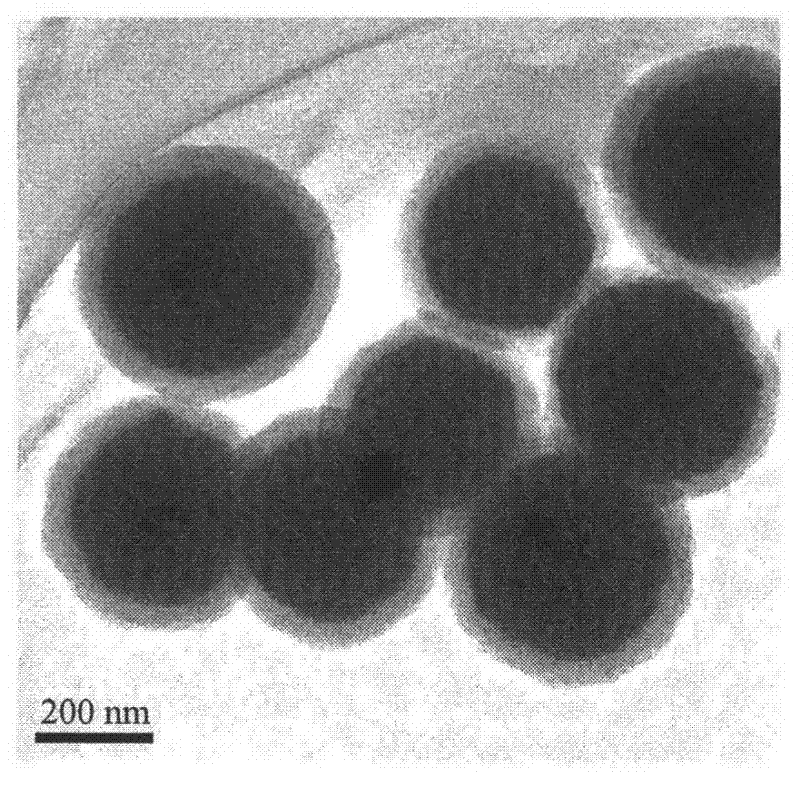

[0019] Embodiment 2: In the 50mL reactor that is equipped with condenser tube, add 35g distilled water, 1g methyl alcohol and 2g ethanol; With 0.01g Fe 3 o 4 Add the microspheres into a 50mL reactor and sonicate for 25min; add 0.008g of MBA (methylenebisacrylamide) and 0.07g of NIPAM (N-isopropylacrylamide) monomer mixture and 0.0025g of APS (ammonium persulfate) Add to the reactor, shake to dissolve; pass N 2 After 28 minutes, gradually raise the temperature to 72°C, and polymerize for 7 hours; magnetically separate the obtained product, pour off the supernatant, add distilled water for ultrasonic dispersion, and then magnetically separate; repeat this process several times to remove excess monomer and polymerization thing. After vacuum drying at room temperature, the magnetic thermosensitive core-shell P(NIPAM-MBA) / Fe 3 o 4 Microspheres.

[0020] After testing, the obtained magnetic temperature-sensitive core-shell P(NIPAM-MBA) / Fe 3 o 4 The particle size of the micro...

Embodiment 3

[0021] Embodiment 3: in the 50mL reactor that is equipped with condenser tube, add 40g distilled water and 5g n-propanol; With 0.015g Fe 3 o 4 Add the microspheres into a 50mL reactor and sonicate for 25min; add 0.015g of MBA (methylenebisacrylamide) and 0.13g of NIPAM (N-isopropylacrylamide) monomer mixture and 0.001g of APS (ammonium persulfate) Add to the reactor, shake to dissolve; pass N 2 After 30 minutes, gradually raise the temperature to 70°C, and polymerize for 8 hours; conduct magnetic separation on the obtained product, pour off the supernatant liquid, add distilled water for ultrasonic dispersion, and then magnetically separate; repeat this process several times to remove excess monomer and polymerization thing. After vacuum drying at room temperature, the magnetic thermosensitive core-shell P(NIPAM-MBA) / Fe 3 o 4 Microspheres.

[0022] After testing, the obtained magnetic temperature-sensitive core-shell P(NIPAM-MBA) / Fe 3 o 4 The particle size of the micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Magnetic responsiveness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com