ABS melt-grafting glycidyl methacrylate and preparation method thereof

A technology of grafting methacrylic acid and glycidyl ester, which is applied in the field of polymer materials, can solve problems such as difficult control, unfavorable large-scale production, and harsh conditions, and achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] 1) Preparation of grafts

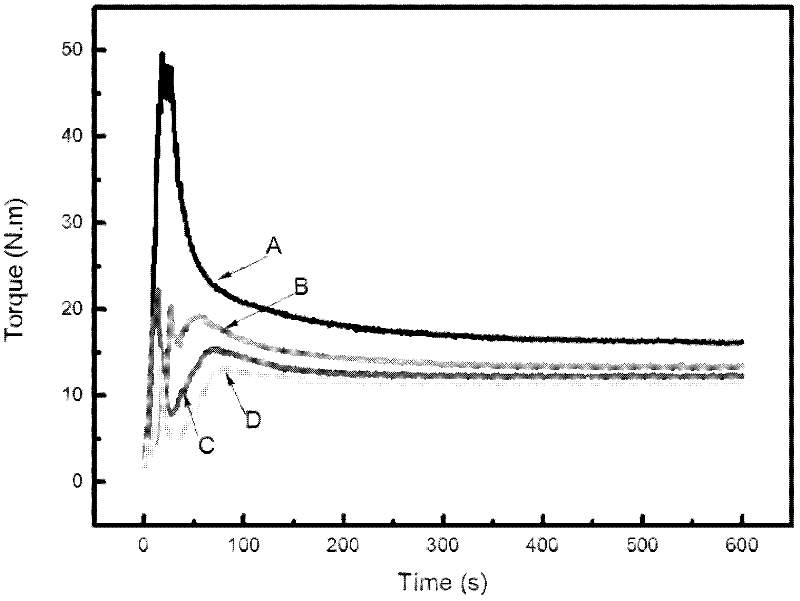

[0034] Dissolve 0.3% dicumyl peroxide initiator, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester antioxidant 1% into 4% methyl In the glycidyl acrylate, stir on a high-speed kneader for 2 minutes, then add the dried 94.5% ABS into the high-speed kneader, and stir for 4 minutes to form a mixture for later use. Put the stirred mixture in the banburying chamber of the torque rheometer for melting and banburying. The technological conditions are: temperature: 220°C, rotating speed: 100r / min, banburying time: 10min. The relationship between torque and time during the banburying process is shown in figure 1 , wherein curve A is the curve of torque changing with time during the banburying process of pure ABS, and curve B is the curve of torque changing with time in this example. It can be seen from curve B that the reaction peak appears at 50-100s, indicating that glycidyl methacrylate and styrene are successfully g...

example 2

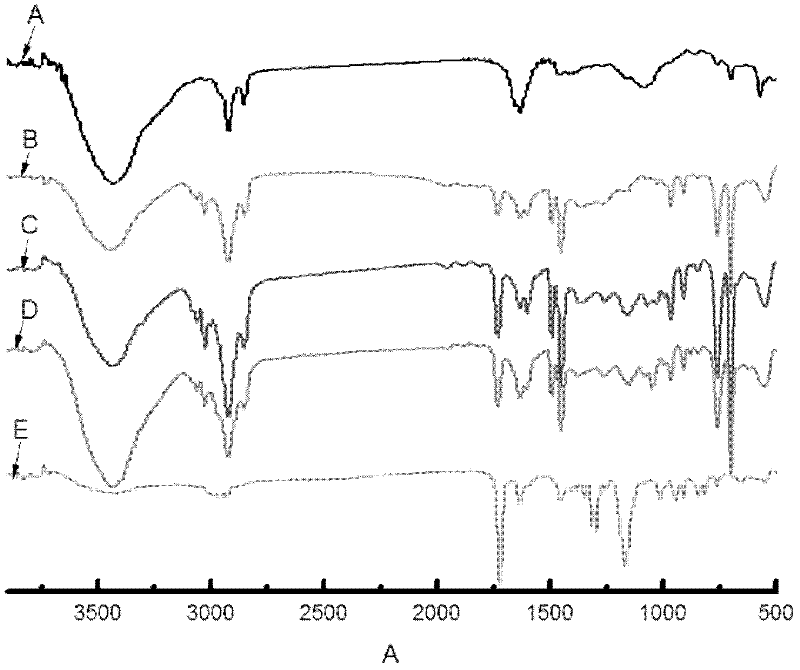

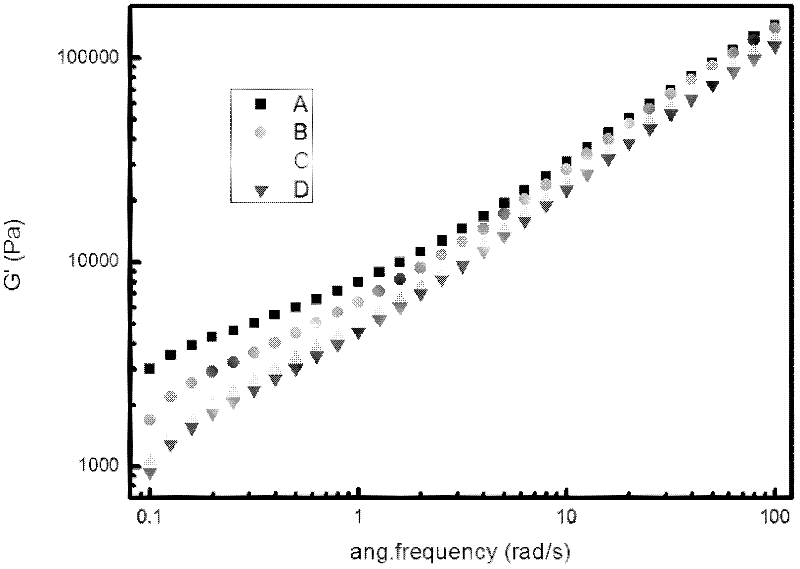

[0041] On the basis of example 1, the consumption of changing glycidyl methacrylate is 6%, the consumption of dicumyl peroxide initiator is 0.4%, and other conditions are unchanged to carry out grafting reaction. figure 1 Middle curve C is the torque curve of this example 2 with time, figure 2 Middle curve C is graft infrared spectrogram in this example 2, image 3 Middle curve C is the dynamic rheological curve of the graft in Example 2.

[0042] According to the infrared spectrum, it can be seen that 1731cm -1 The strong vibrational absorption peak is the characteristic absorption peak of the carbonyl group (C=O) in the GMA molecule, at 967, 910, 846cm -1 The three weak continuous vibration peaks that exist at are the skeleton vibration peaks of the epoxy group in the GMA molecule, which also prove that GMA is successfully grafted onto ABS. From the dynamic rheological curve C, it can be seen that the reaction peak appeared at 60-120s, indicating that glycidyl methacryla...

example 3

[0044] On the basis of example 1, the consumption of changing glycidyl methacrylate is 8%, the consumption of dicumyl peroxide initiator is 0.5%, and other conditions are unchanged to carry out grafting reaction. figure 1 Middle curve D is the torque curve with time of this example 3, figure 2 Middle curve D is graft infrared spectrogram in this example 3, image 3 The middle curve D is the dynamic rheological curve of the graft in Example 3.

[0045] According to the infrared spectrum, it can be seen that 1731cm -1 The strong vibrational absorption peak is the characteristic absorption peak of the carbonyl group (C=O) in the GMA molecule, at 967, 910, 846cm -1 The three weak continuous vibration peaks that exist at are the skeleton vibration peaks of the epoxy group in the GMA molecule, which also prove that GMA is successfully grafted onto ABS. From the dynamic rheological curve C, it can be seen that the reaction peak appeared at 70-120s, indicating that glycidyl methac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com