Epoxy under-fill adhesive capable of quickly curing at low temperature and preparation method thereof

An underfill and rapid curing technology, which is applied in semiconductor/solid-state device components, electric solid-state devices, electrical components, etc., can solve the problems of late start of epoxy packaging materials, difficulty in adapting to quality and performance, influence and restriction, etc. Achieve the effect of meeting urgent needs, promoting development, and having a long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

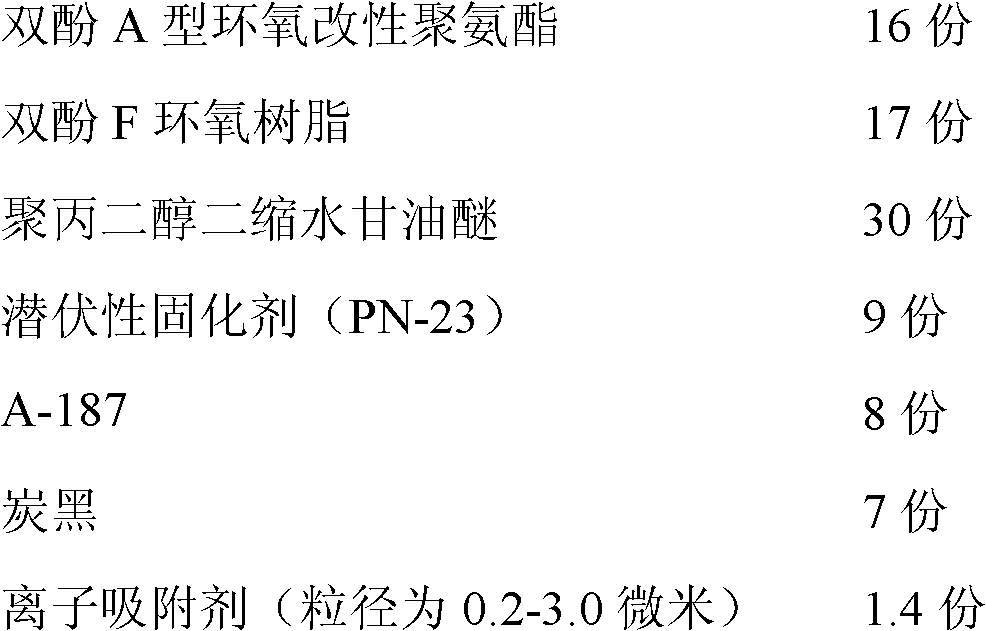

[0025] 1. The epoxy underfill adhesive that can be cured quickly at low temperature in this embodiment is composed of raw materials in parts by weight:

[0026]

[0027]

[0028] 2. The preparation method of epoxy underfill in this embodiment is as follows:

[0029] (a) bisphenol A type epoxy-modified polyurethane, bisphenol F epoxy resin and carbon black are mixed homogeneously; Then add silicon micropowder and mix homogeneously;

[0030] (b) After adding the curing agent and mixing evenly in the reaction kettle, the vacuum degree is -0.1Mpa, and the vacuum is pumped for 30min;

[0031] (c) Add A-187, polypropylene glycol diglycidyl ether, ion adsorbent, and polyethylene oxide alkyl ether and mix evenly. The vacuum degree is -0.1Mpa, and the vacuum is pumped for 30 minutes to obtain the product.

Embodiment 2

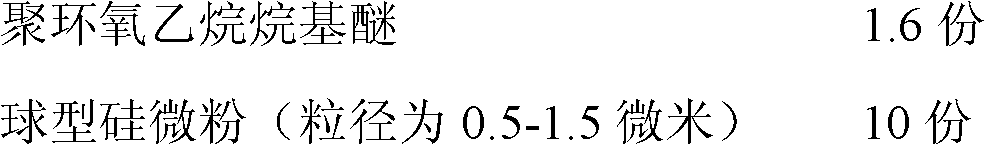

[0033] 1. The epoxy underfill adhesive that can be cured quickly at low temperature in this embodiment is composed of raw materials in parts by weight:

[0034]

[0035] 2. The preparation method of epoxy underfill in this embodiment is as follows:

[0036] (a) bisphenol A type epoxy-modified polyurethane, bisphenol F epoxy resin and carbon black are mixed homogeneously; Then add silicon micropowder and mix homogeneously;

[0037] (b) After adding the curing agent and mixing evenly in the reaction kettle, the vacuum degree is -0.1Mpa, and the vacuum is pumped for 60min;

[0038] (c) Add KBM-403, diglycidyl ether, ion adsorbent, and sorbitan fatty acid ester and mix evenly. The vacuum degree is -0.1Mpa, and the vacuum is pumped for 60 minutes to obtain the product.

Embodiment 3

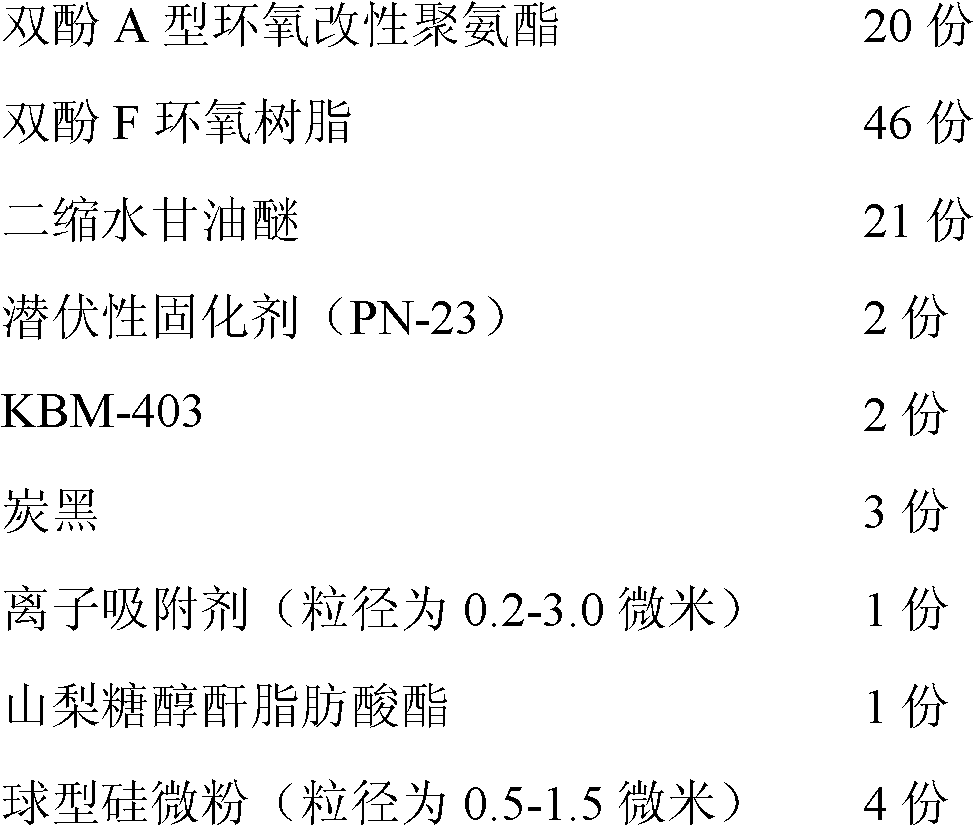

[0040] 1. The epoxy underfill adhesive that can be cured quickly at low temperature in this embodiment is composed of raw materials in parts by weight:

[0041]

[0042]

[0043] Wherein, the surfactant is a combination of polyethylene oxide alkyl ether: sorbitan fatty acid ester=1:1 by weight.

[0044] 2. The preparation method of epoxy underfill in this embodiment is as follows:

[0045] (a) bisphenol A type epoxy-modified polyurethane, bisphenol F epoxy resin and carbon black are mixed homogeneously; Then add silicon micropowder and mix homogeneously;

[0046] (b) After adding the curing agent and mixing evenly in the reaction kettle, the vacuum degree is -0.1Mpa, and the vacuum is pumped for 50min;

[0047] (c) Add KH-560, adipate glycidyl ether, ion adsorbent, and surfactant and mix evenly. The vacuum degree is -0.1Mpa, and the vacuum is pumped for 50 minutes to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com