Niobium-zirconium tungstate composite material and preparation method thereof

A composite material, zirconium tungstate technology, applied in the field of composite materials, can solve problems such as easy expansion and poor strength, achieve excellent performance, improve high temperature strength, and avoid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The niobium-zirconium tungstate composite material of this embodiment is made of the following raw materials in mass percentage: 60% of zirconium tungstate, 5% of chromium, and 35% of niobium; the mass purity of the zirconium tungstate is not less than 97%, and the The mass purity is not less than 99%; the zirconium tungstate is zirconium tungstate powder with a particle size not greater than 5 μm, the chromium is chromium powder with a particle size not greater than 6 μm, and the niobium is niobium powder with a particle size not greater than 3 μm.

[0022] The preparation method of the composite material of the present embodiment comprises the following steps:

[0023] Step 1. Weigh the raw materials according to the mass percentage, then place the weighed raw materials in a planetary ball mill, use absolute ethanol as a dispersant, and ball mill and mix under the conditions that the rotating speed of the ball mill is 400rpm and the ball-to-material ratio is 5:1. 20h,...

Embodiment 2

[0028] This embodiment is the same as Embodiment 1, except that the niobium-zirconium tungstate composite material is made of the following raw materials in mass percentage: 35% zirconium tungstate, 10% chromium, and 55% niobium.

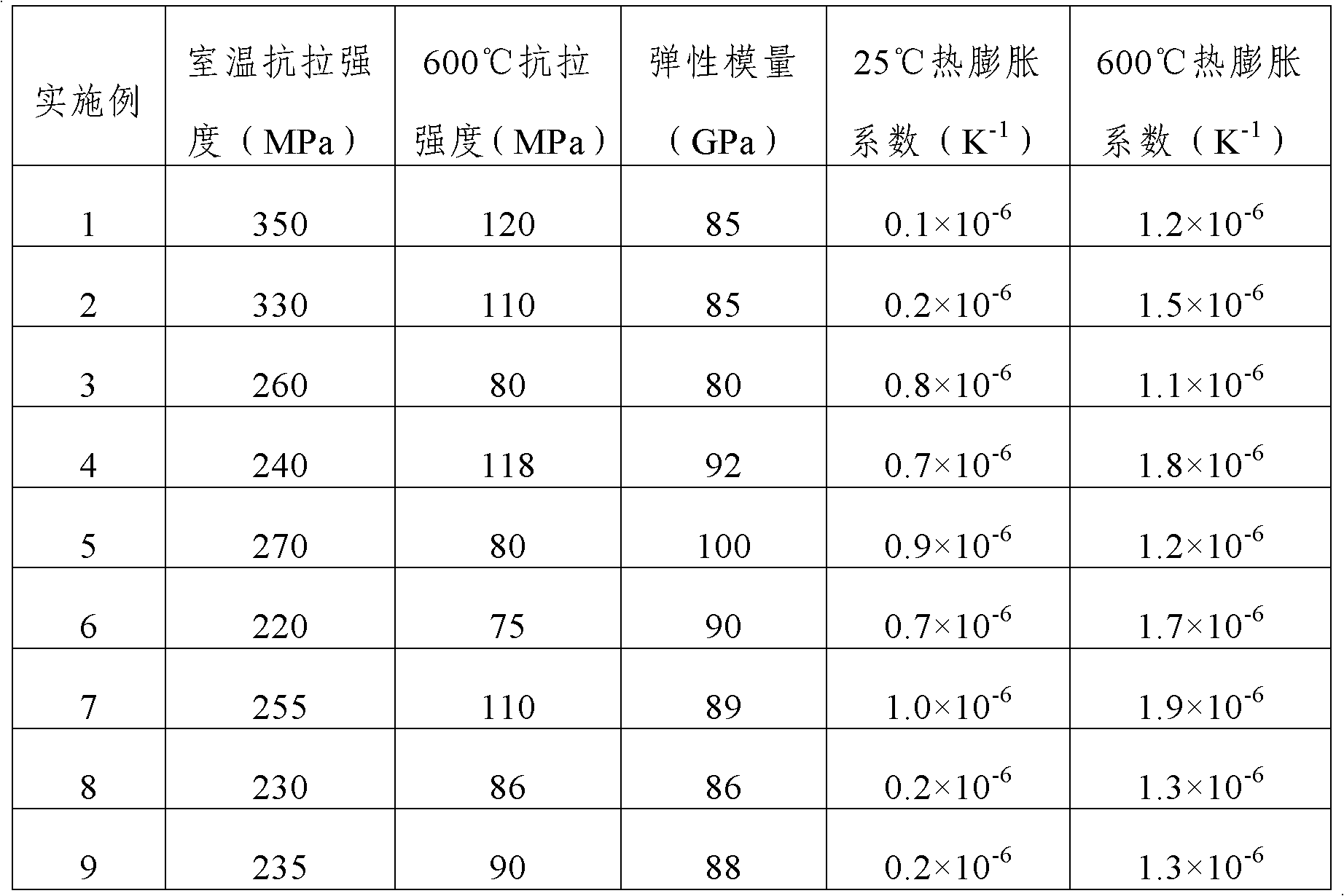

[0029] The performance testing results of the niobium-zirconium tungstate composite material prepared in this example are shown in Table 1.

Embodiment 3

[0031] This embodiment is the same as Embodiment 1, except that the niobium-zirconium tungstate composite material is made of the following raw materials in mass percentage: 75% zirconium tungstate, 1% chromium, and 24% niobium.

[0032] The performance testing results of the niobium-zirconium tungstate composite material prepared in this example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com