Roller-replacing trolley

A roll changing trolley and pulling trolley technology, applied in coating, metal material coating process, hot dip plating process, etc., can solve the problems of low efficiency and difficult replacement, reduce production cost and reduce roll changing time , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

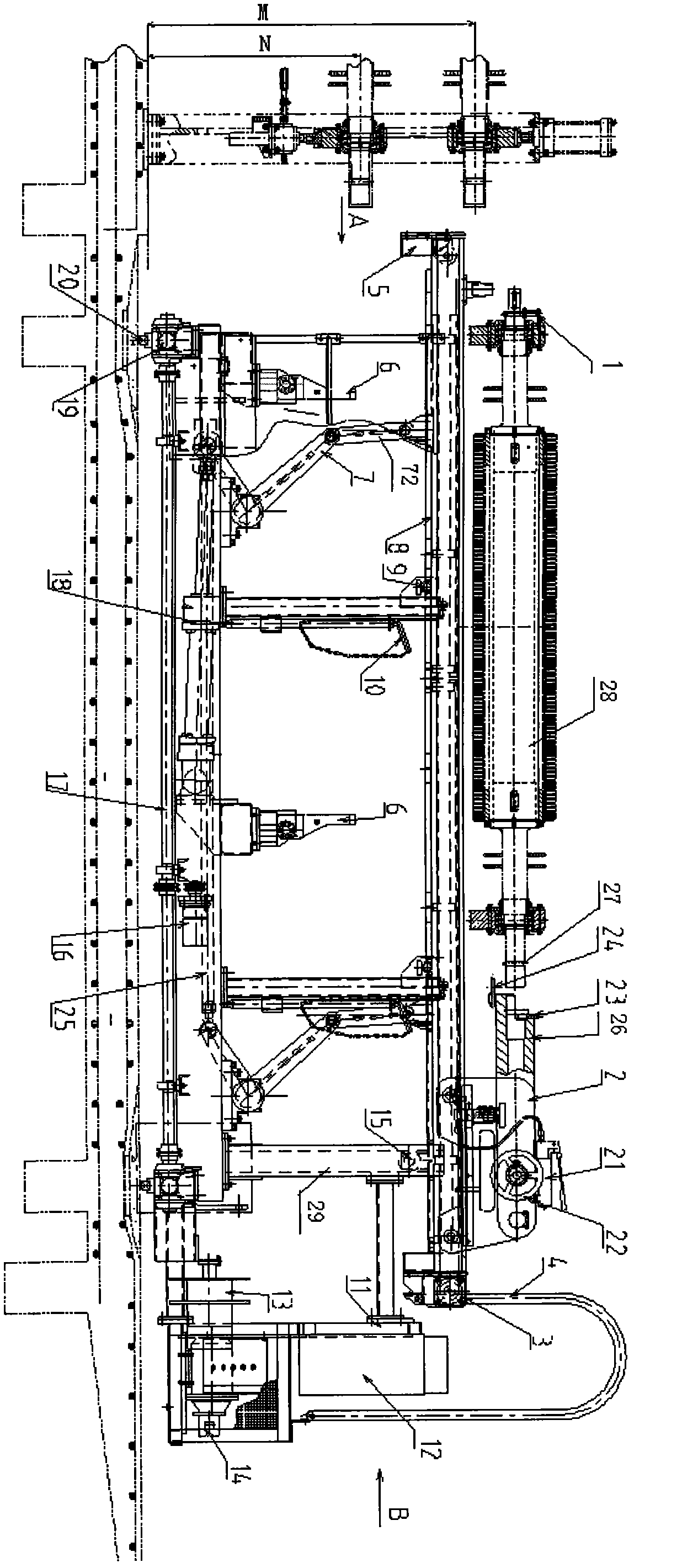

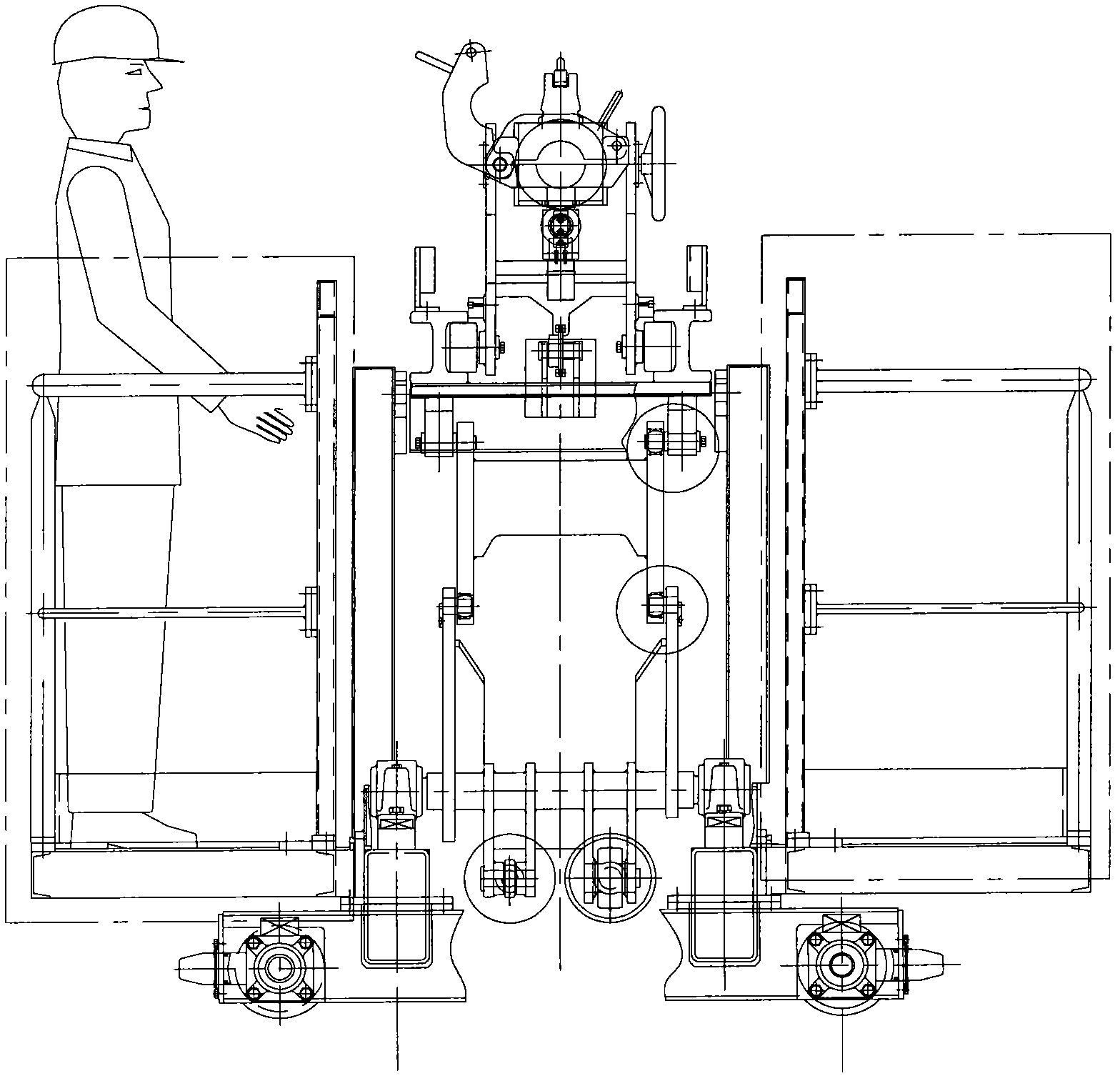

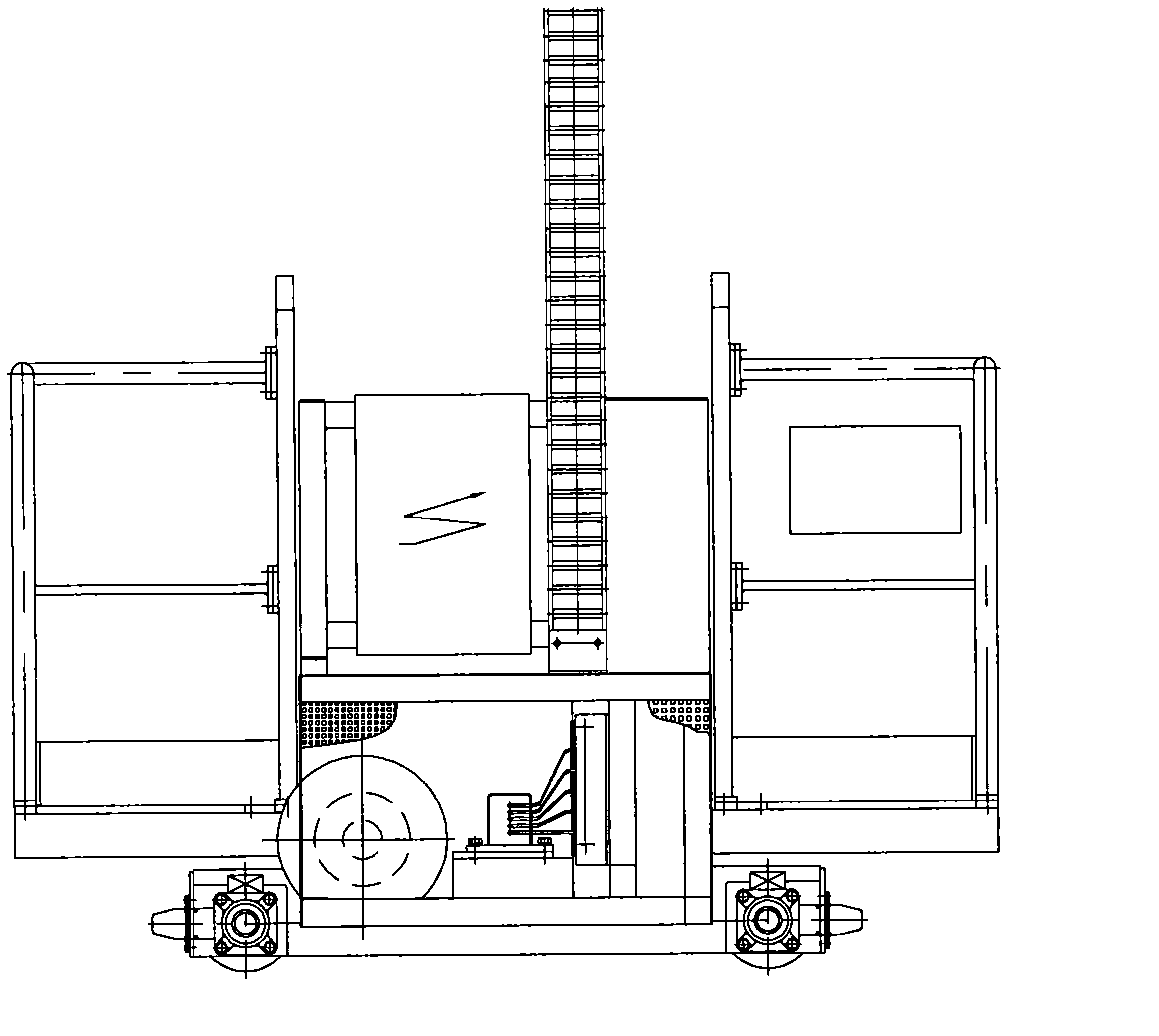

[0012] The structure of the roller changing trolley in the degreasing section of the continuous galvanizing and annealing line involved in the present invention is as follows: figure 1 shown. Brush rolls and support rolls need to be replaced and repaired after working for a long time in the degreasing section of the galvanizing and annealing line. Due to the relationship between structure and assembly, manual hoisting is not easy to replace, so the roll changing trolley was designed and invented.

[0013] The roller changing trolley of the present invention is mainly composed of the following parts: roller bearing seat positioning chuck (1), roller traction trolley (2), traction motor, motor drive traction mechanism (3), motor oil supply drag chain (4), transmission Chain fixing mechanism (5), roller support frame (6), connecting rod elevating mechanism (7), rocking arm (71), two force bar (72), support frame (8), support block (9), support bar ( 10), electric control box bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com