Device and method for measuring surface defect of semiconductor material

A technology for measuring devices and measuring methods, applied in measuring devices, material excitation analysis, instruments, etc., can solve problems such as low luminous efficiency, difficulty in measuring spectra, low carrier injection energy density, etc., and achieve excellent signal-to-noise ratio, shielding The effect of measuring the impact of the outcome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

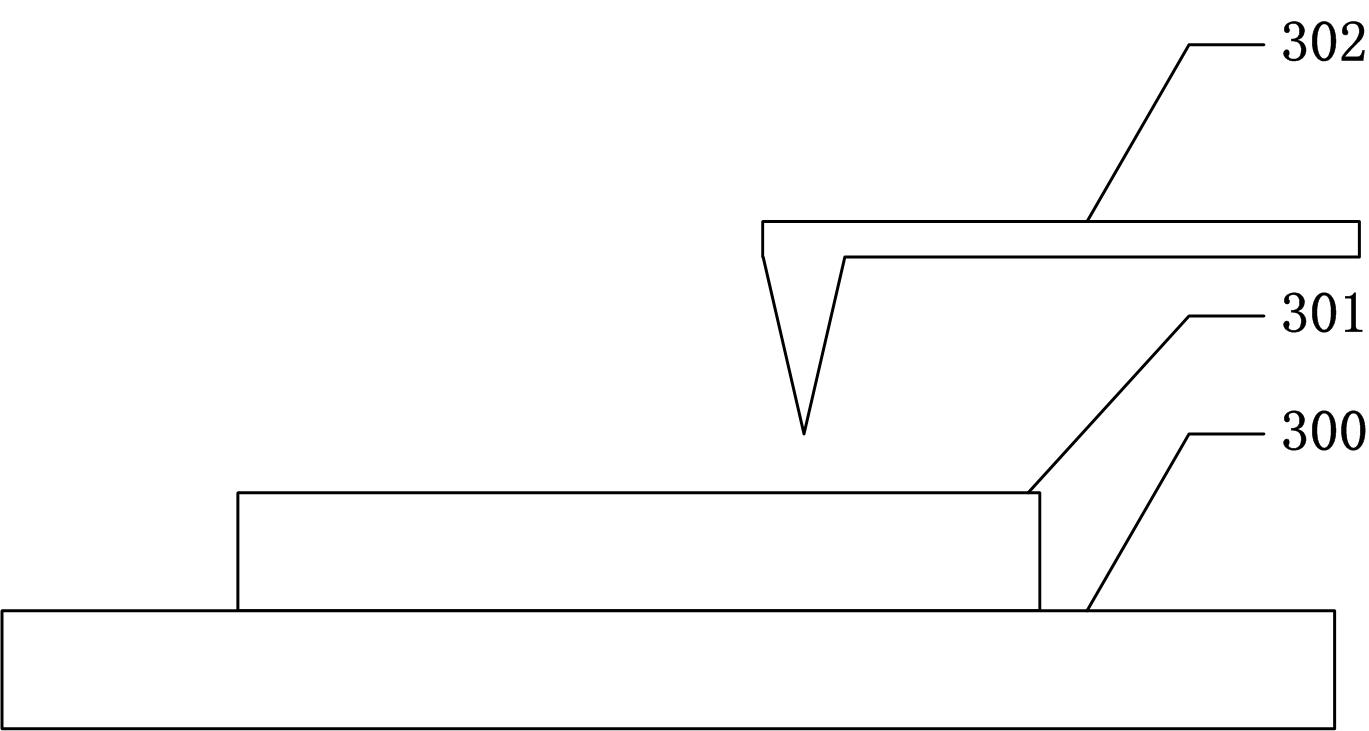

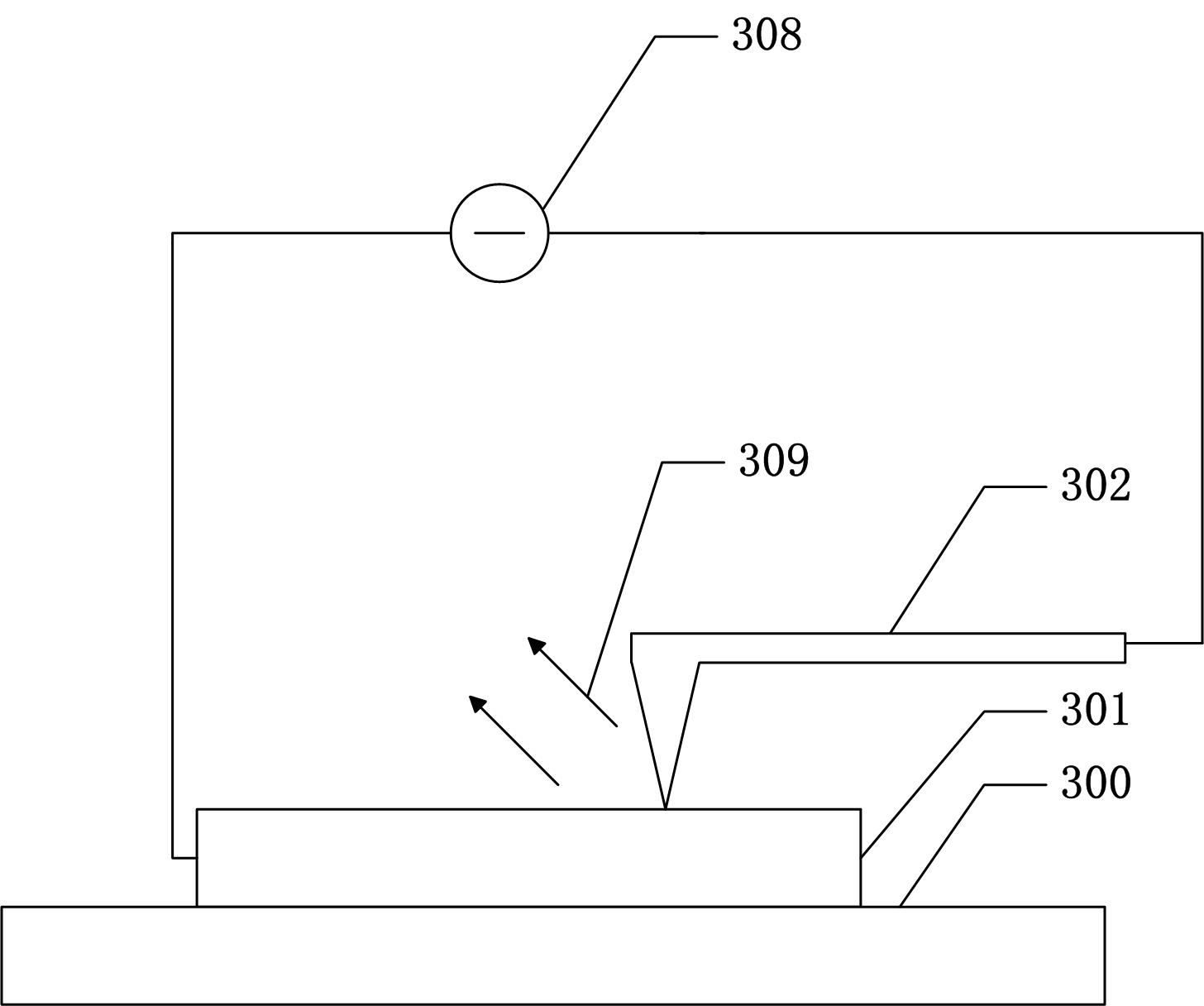

[0038] figure 1Shown is a semiconductor material surface defect measurement device provided by the present invention, including: an atomic force microscope conductive probe 302, the atomic force microscope conductive probe 302 includes a cantilever beam 302b and a tip 302a at the end of the cantilever beam 302b, for Contact with the sample 301 to be tested and inject current into the exposed surface of the sample 301 to be tested; an atomic force microscope control device is mechanically connected with the conductive probe 302 of the atomic force microscope; an optical microscope system 304 is used to collect the surface of the sample 301 to be tested Electroluminescence 309 emitted from the exposed surface; a three-dimensionally movable sample stage 300 for placing the sample 301 to be tested; and a photodetector 306 for detecting the signal of the electroluminescence 309 .

[0039] The measuring device further includes a voltage source 308, one end is electrically connected ...

Embodiment 2

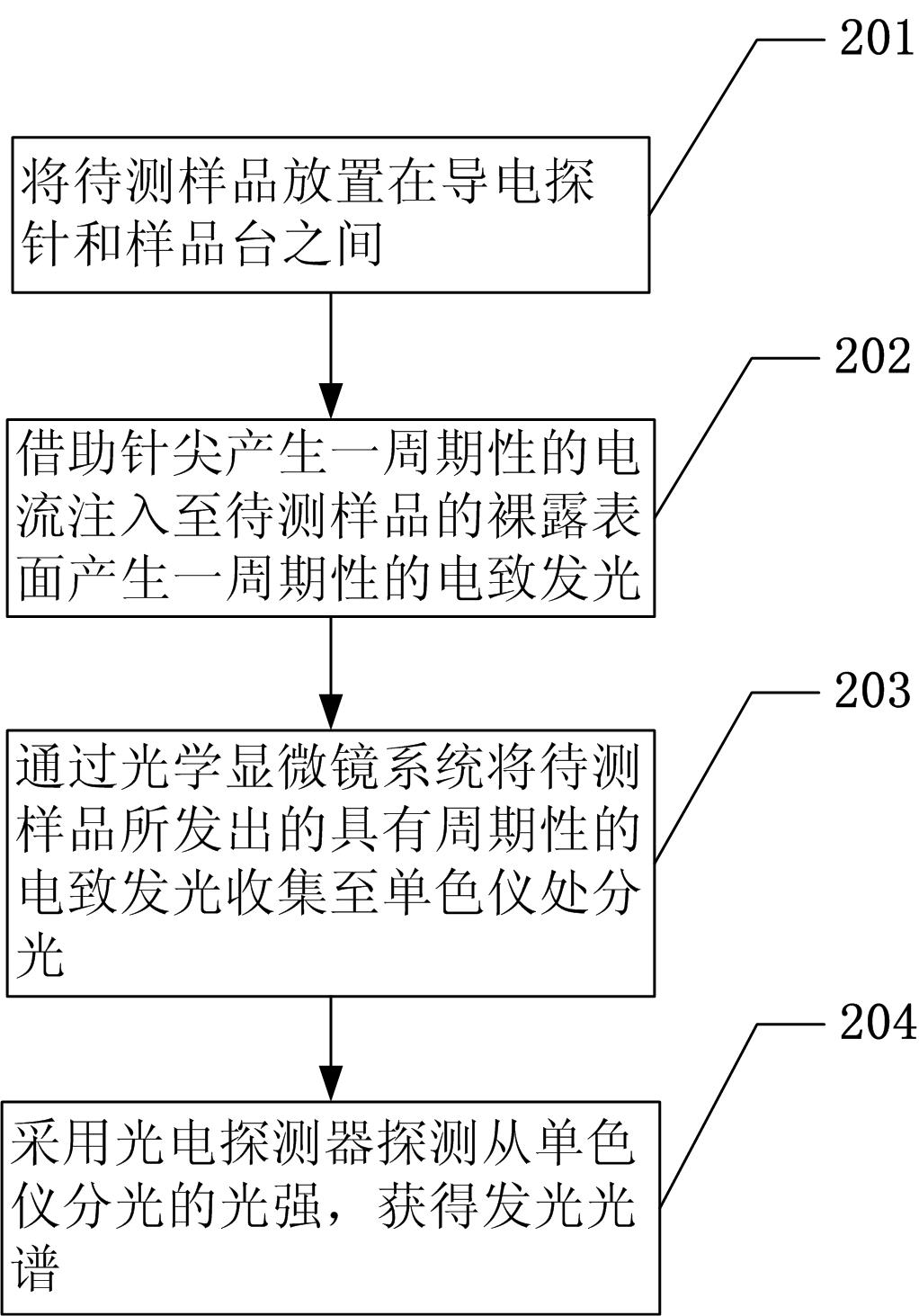

[0046] figure 2 Shown is the flow chart of the second step of the embodiment of the surface defect measurement method provided by the present invention, including: step 201, placing the sample to be tested between the conductive probe of the atomic force microscope and the sample stage; step 202, generating a periodic The current is injected into the exposed surface of the sample to be tested to generate a periodical electroluminescence; step 203, the periodic electroluminescence emitted by the sample to be tested is collected by the optical microscope system to the monochromator for light distribution; step 204, A photodetector is used to detect the light intensity split from the monochromator to obtain a luminescence spectrum.

[0047] Figure 3A Shown is step 201 of the second embodiment of the surface defect measurement method provided by the present invention, a sample 301 to be tested is placed between the sample stage 300 and the conductive probe 302 of the atomic for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com