Low-resistance serial welding structure for solar cell component

A solar module and welding structure technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of unfavorable solar cell module power, affecting the normal output of the battery module, and large connection resistance of the battery sheet, so as to improve the power output, Eliminate short-circuit defects and improve the effect of effective lighting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

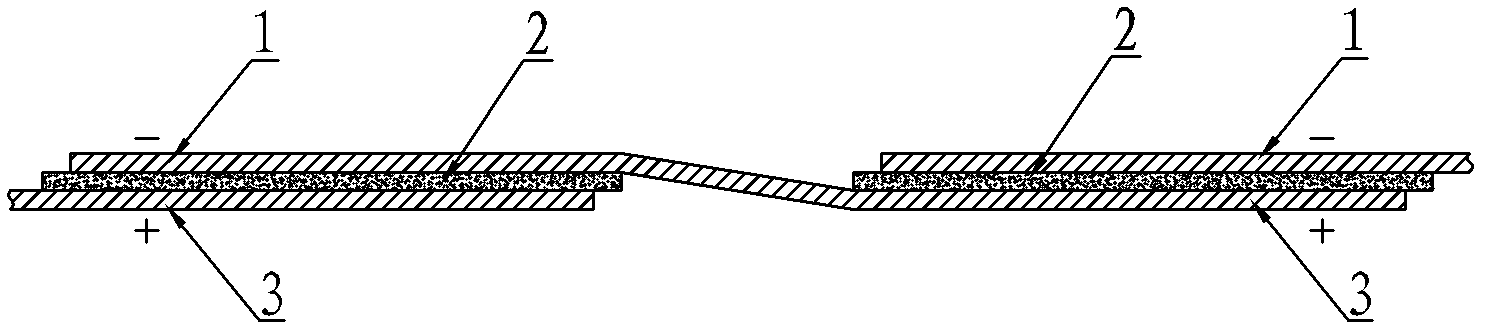

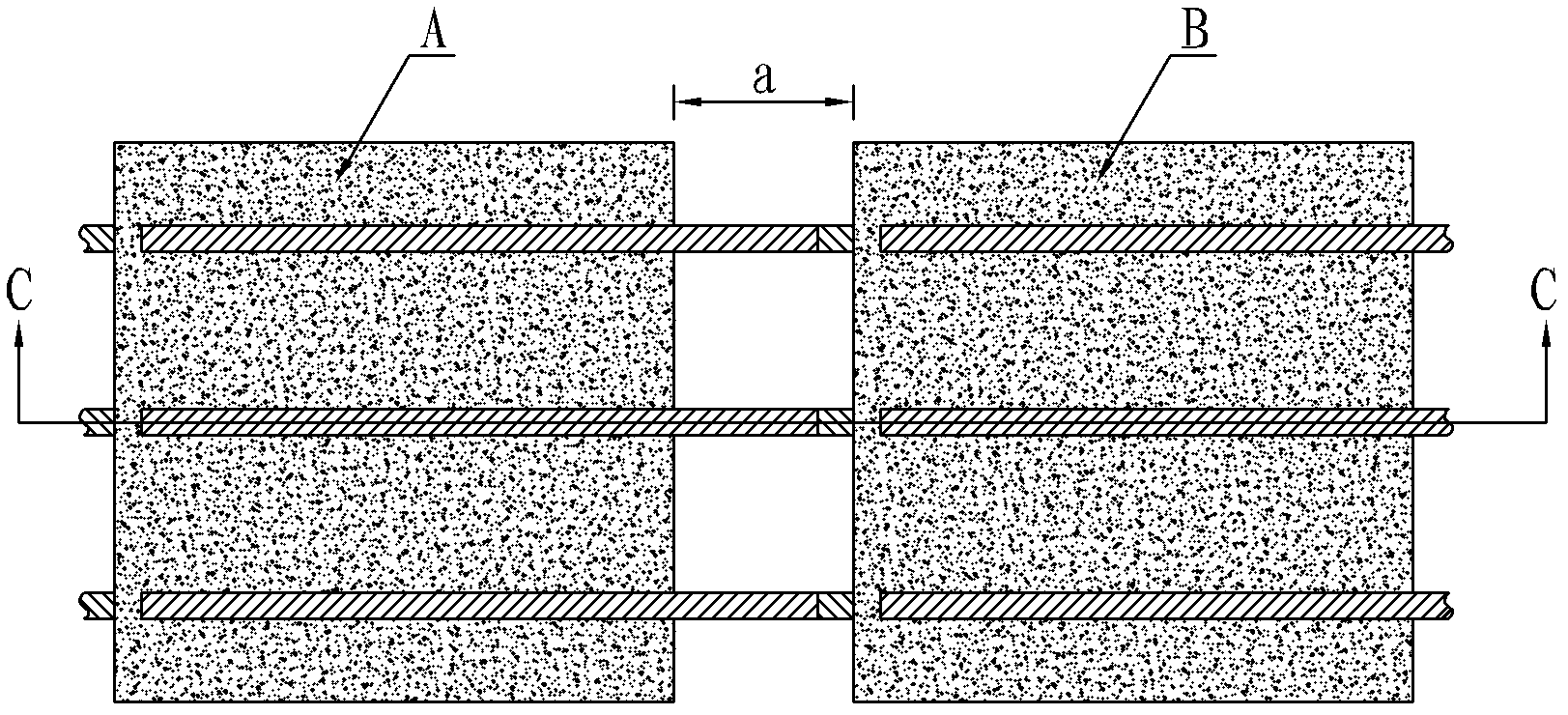

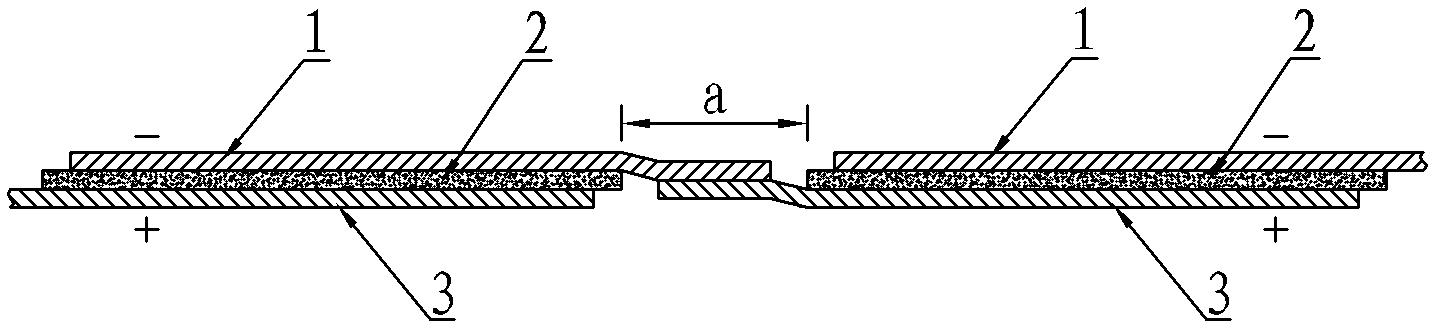

[0016] A low-resistance series welding structure of a solar module cell, comprising a cell A and a cell B adjacent to each other, the cell A and the cell B having the same structure are composed of a negative electrode 1, a silicon cell 2 and a positive electrode 3 Composition, the negative electrode 1 and the positive electrode 3 are respectively arranged on the lighting surface and the backlight surface of the battery silicon wafer 2, and the negative electrode 1 is located above the positive electrode 3, and the distance between the A battery piece A and the B battery piece B is a , the length of the negative electrode 1 on A battery sheet A extending to B battery sheet B is 4 / 5a, and the other end is retracted 3 mm inside the battery silicon sheet 2, and the positive electrode 3 on B battery sheet B extends to the adjacent A battery sheet One end of cell A protrudes to a length of 4 / 5a, and the other end shrinks 3mm inside the cell silicon chip 2. The negative electrode 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com