Preparation method for alkaline anion-exchange membrane electrode

An alkaline anion, exchange membrane technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high corrosion resistance, high demand, asbestos film thickness, etc., to improve the anion exchange rate, expand the scope of use, The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

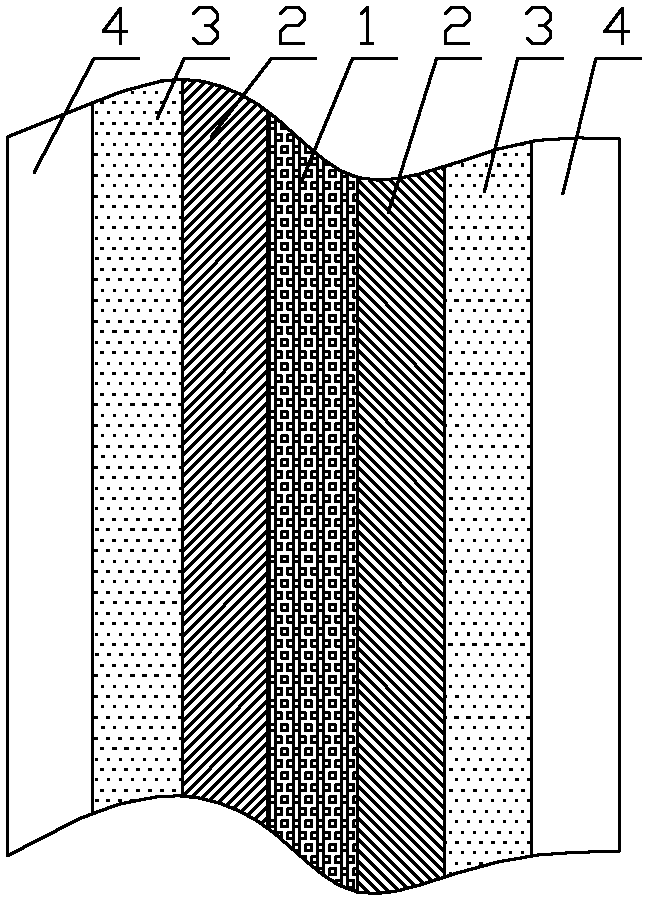

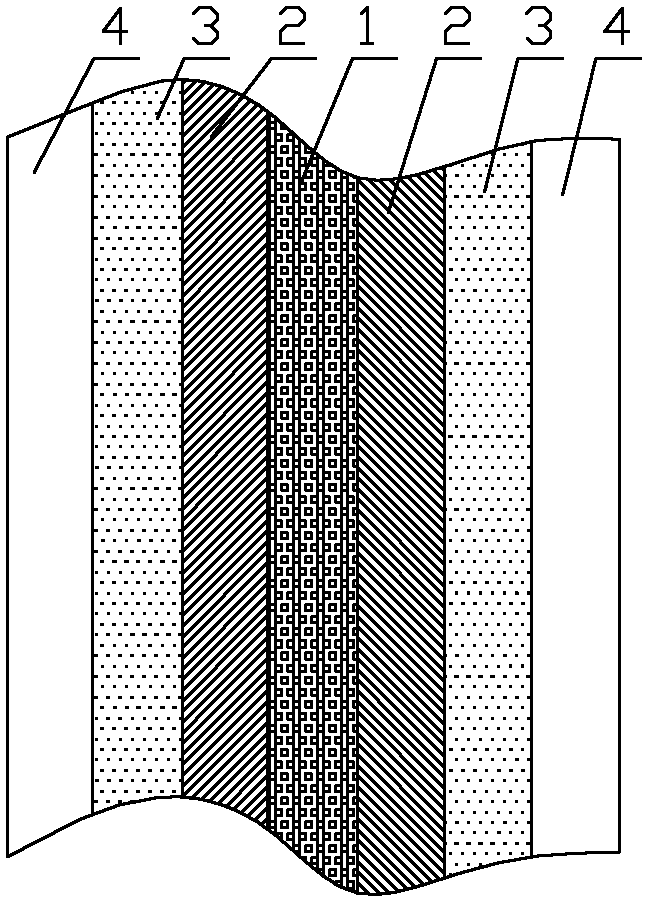

[0022] The preparation method of alkaline anion exchange membrane electrode, the step comprises:

[0023] ⑴Fix the alkaline anion exchange membrane with a thickness of 0.16-0.25mm on the return frame, and spray a layer of deionized water with a mass ratio of 70-80% and 20-30% deionized water on both sides of the exchange membrane in the frame. The suspension that basic anion resin is mixed into is used as spraying material, and dries under natural environment, and each of two sides of basic anion exchange membrane forms a layer of binding agent; When the air pressure reaches 2-0.3MPa, start the spray gun, and the spray material will be sprayed evenly through the small hole in the mouth of the spray gun;

[0024] ⑵According to the area of the binder in step ⑴, according to 2-5mg / cm 2 Weigh the Pt / C catalyst, add nano-conductive carbon black with a mass ratio of 40-60% to Pt / C, add 5-20g of deionized water and 5-20g of solvent, and stir well to make a catalyst mixed slurry A...

Embodiment 1

[0028] ⑴ Select the Neosepta series AHA type 0.2mm anion exchange membrane from Tokuyama Company in Japan, fully soak it in NaOH solution, rinse it with clean water, and use it as the basic anion exchange membrane 1. Fix the alkaline anion exchange membrane on the back frame, the inner frame The area is 50cm 2 Get 0.5g Japanese Tokuyama company anionic resin, add 2g deionized water, form suspension liquid binder after fully stirring, binder is put into the feed bin of high-pressure gas spray gun, the air pressure of high-pressure gas spray gun is adjusted to 0.2MPa, The binder is evenly sprayed onto both sides of the basic anion exchange membrane, and dried in a natural environment;

[0029] (2) Weigh two parts of 0.2g 50%Pt / C catalyst and 0.3g nano-conductive carbon black, respectively add 8g deionized water and 8g isopropanol, stir well, and configure two parts of mixed slurry; Put the mixed slurry into the feed bin of the high-pressure gas spray gun, adjust the air pressur...

Embodiment 2

[0033] (1) Select a 0.2mm thick Morgane-ADP alkaline anion exchange membrane, fully soak it in NaOH solution, rinse it with clean water, and use it as an alkaline anion exchange membrane. Fix the alkaline anion exchange membrane on the back-shaped frame, and the inner frame area is 50cm 2Get 0.8 g Japan Tokuyama company anionic resin, add 2g deionized water, form suspension liquid binder after fully stirring, binder is put into high-pressure gas spray gun feed bin, the air pressure of high-pressure gas spray gun is adjusted to 0.2MPa, will The binder is uniformly sprayed on both sides of the alkaline anion exchange membrane, and dried in a natural environment.

[0034] (2) Weigh two parts of 0.4g 40%Pt / C catalyst and 0.6g nano-conductive carbon black respectively, add 15g deionized water and 15g isopropanol, stir well, and configure two parts of mixed slurry; mix one part Put the slurry into the feed bin in the high-pressure gas spray gun, adjust the air pressure of the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com