Surface modification method of carbon nanotube, carbon nanotube and application thereof

A technology of carbon nanotubes and modification methods, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems such as weak interaction, poor adsorption effect, and lack of functional groups , to achieve the effect of high reuse rate, easy separation and enhanced adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

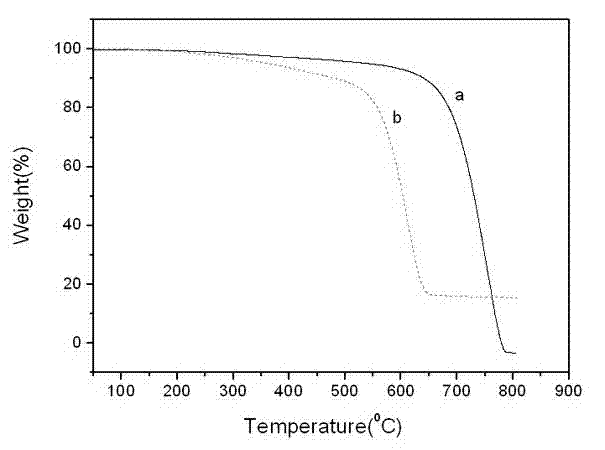

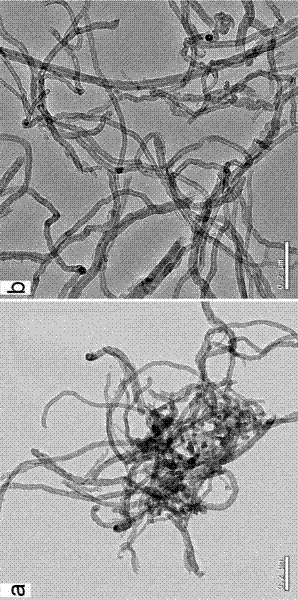

[0021] Add 1.0 g of multi-walled carbon nanotubes into 100 g of concentrated nitric acid, and heat to reflux for 24 hours at 100° C. with stirring. After cooling to room temperature, high-speed centrifugal separation, the solid was washed with deionized water to a pH value of 7, and vacuum-dried at 50° C. for 12 hours to obtain acidified multi-walled carbon nanotubes.

[0022] Mix 200 mg of acidified carbon nanotubes, 40 g of dimethylformamide and 100 g of thionyl chloride, and ultrasonically disperse for 10 minutes. The reaction was then stirred at a temperature of 70°C for 20 hours. Excess thionyl chloride was removed by distillation under reduced pressure. The solid product was filtered with a nylon membrane, washed with tetrahydrofuran, and vacuum-dried at 50° C. for 24 hours to obtain acyl chloride carbon nanotubes.

[0023] Add 100 mg of carbonyl chloride carbon nanotubes and 100 mg of sodium p-aminobenzenesulfonate to 5 g of dimethylformamide, and ultrasonically dispe...

Embodiment 2

[0026] Add 1.0 g of single-walled carbon nanotubes into 200 g of concentrated nitric acid, and heat to reflux for 12 hours at 80° C. with stirring. After cooling to room temperature, high-speed centrifugation, the solid was washed with deionized water to a pH value of 7, and vacuum-dried at 70° C. for 10 hours to obtain acidified multi-walled carbon nanotubes.

[0027] Mix 200 mg of acidified carbon nanotubes, 10 g of dimethylformamide and 40 g of thionyl chloride, and ultrasonically disperse for 30 minutes. The reaction was then stirred at a temperature of 100° C. for 30 hours. Excess thionyl chloride was removed by distillation under reduced pressure. The solid product was filtered with a nylon filter membrane, washed with tetrahydrofuran, and dried under vacuum at 60°C for 18 hours to obtain acyl chloride carbon nanotubes.

[0028]Add 100 mg of acyl chloride carbon nanotubes and 200 mg of sodium p-aminobenzenesulfonate into 10 g of dimethylformamide, and disperse ultrason...

Embodiment 3

[0031] Add 1.0 g of single-walled carbon nanotubes into 150 g of concentrated nitric acid, and heat to reflux for 18 hours at 90° C. with stirring. After cooling to room temperature, high-speed centrifugation, the solid was washed with deionized water to a pH value of 7, and vacuum-dried at 70° C. for 6 hours to obtain acidified multi-walled carbon nanotubes.

[0032] Mix 200 mg of acidified carbon nanotubes, 30 g of dimethylformamide and 60 g of thionyl chloride, and ultrasonically disperse for 30 minutes. The reaction was then stirred at a temperature of 90°C for 25 hours. Excess thionyl chloride was removed by distillation under reduced pressure. The solid product was filtered with a nylon filter membrane, washed with tetrahydrofuran, and dried under vacuum at 70°C for 12 hours to obtain acyl chloride carbon nanotubes.

[0033] Add 100 mg of acyl chloride carbon nanotubes and 150 mg of sodium p-aminobenzenesulfonate into 15 g of dimethylformamide, and disperse ultrasonica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com