Preparation method and application of adsorbent of organic and inorganic composite material

A technology of inorganic composite materials and adsorbents, applied in the field of organic-inorganic composite adsorbents, the preparation of organic-inorganic composite adsorbents, and organic pollutants, can solve the problem of organic pollutants in water without organic-inorganic composite materials and other issues, to achieve the effect of high utilization rate, efficient utilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

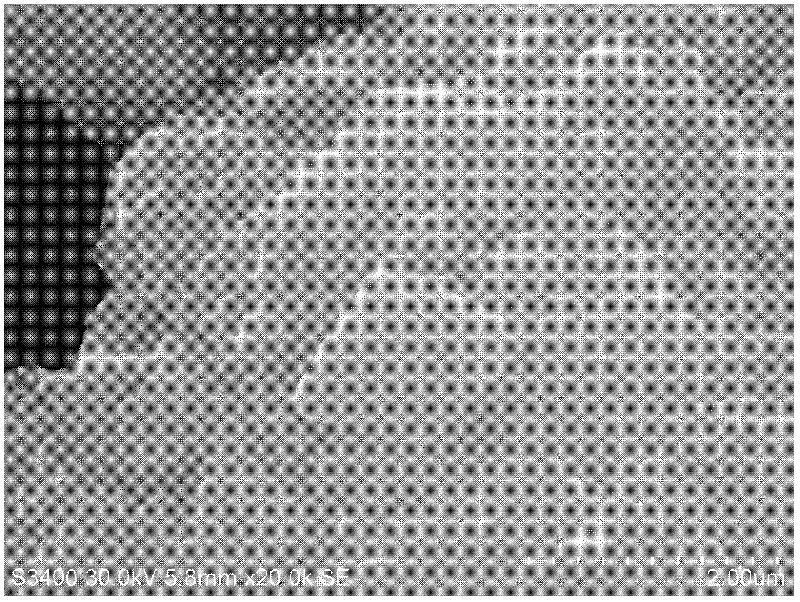

Image

Examples

Embodiment 1

[0020] (1) Get natural zeolite, after adopting distilled water to clean several times, blast air-drying, crushing, grinding, cross 200 mesh sieves for subsequent use; Be that the chitosan solution of 2% with concentration is the chitosan solution preparation concentration of 2% with concentration; Preparation concentration For 25mmol / L cetylpyridinium bromide (CPB) stock solution for later use.

[0021] (2) Take 20g of spare natural zeolite, place it in a distilled water reactor containing 200mL, stir to make the natural zeolite in suspension; weigh 200mL of chitosan solution and fully mix it with the suspended natural zeolite, drop it into the reaction solution Add a sodium hydroxide solution with a concentration of 2.0mol / L until the reaction liquid appears obvious flocs and continue to stir for 15 minutes; then centrifuge and wash the solid repeatedly with distilled water until the pH of the supernatant is close to 7.0, and place the solid in After drying at 105°C, grind an...

Embodiment 2

[0026] (1) Get the natural zeolite, first adopt 1mol / L sodium chloride solution to clean (the liquid-solid ratio of the sodium chloride solution and the natural zeolite is 10mL / g), then use distilled water to clean several times, air-dried, broken, Grinding and passing through a 200-mesh sieve for future use; preparing a 2% chitosan solution with a concentration of 2% acetic acid solution for future use; preparing a cetylpyridinium bromide (CPB) stock solution with a concentration of 25 mmol / L for future use.

[0027] (2) Get 20g of standby zeolite, place it in a distilled water reactor filled with 200mL, stir to make the zeolite in suspension; weigh 100mL of chitosan solution and fully mix the suspended zeolite, add dropwise the concentration of zeolite in the reaction solution. 2.0mol / L sodium hydroxide solution, continue to stir for 15 minutes until the reaction solution appears flocculent; then centrifuge, wash the solid with distilled water repeatedly until the pH of the s...

Embodiment 3

[0032] (1) Get natural zeolite, after adopting distilled water to clean several times, blast air-drying, crushing, grinding, cross 200 mesh sieves for subsequent use; Be that the chitosan solution of 2% with concentration is the chitosan solution preparation concentration of 2% with concentration; Preparation concentration It is used as 25mmol / L hexadecyltrimethylammonium bromide (HTAB) stock solution for future use.

[0033] (2) Take 5g of spare zeolite, place it in a 50mL distilled water reactor, stir to make the natural zeolite in suspension; weigh 50mL of chitosan solution and fully mix the suspended natural zeolite, add dropwise to the reaction solution Sodium hydroxide solution with a concentration of 2.0mol / L, and continue stirring for 15 minutes until the reaction liquid has obvious flocculents; then centrifuged, and the solid is washed repeatedly with distilled water until the pH of the supernatant is close to 7.0, and the solid is placed in 105 After drying at ℃, gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com