Double oxide composite type super thermite and preparation method thereof

A super thermite, double oxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve practical application discount, high reactivity, easy problems such as agglomeration surface, to achieve the effect of high safety performance, high purity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 2.128 g of copper nitrate trihydrate and completely dissolve it in 15 mL of absolute ethanol under ultrasonic oscillation;

[0039] (2) Slowly add 5 mL of 1,2-propylene oxide dropwise to the above suspension, add 0.3003 g of nano-aluminum powder under the action of ultrasonic oscillation after 4 min, and then add 0.70 g of nano-lead oxide (30-80nm), Continue ultrasonic oscillation at a constant temperature of 48 °C for 1 h to form a wet gel, then cool and stand still;

[0040] (3) The wet gel after static aging was dried in a vacuum drying oven at 80 °C for 24 h to obtain a dry gel, and then the ground xerogel was calcined in a muffle furnace at 439 °C for 2.5 h, namely Double oxide composite super thermite Al / CuO·PbO can be obtained.

[0041] The inventor changed the formula within the range of 1-4 parts of Al powder, 1-8 parts of CuO, and 1-8 parts of PbO, and prepared composite super thermites with different compositions.

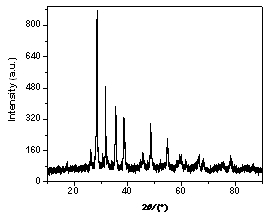

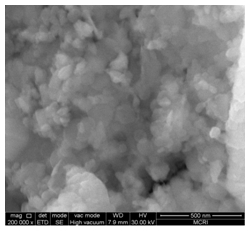

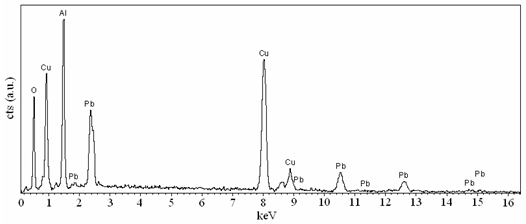

[0042] The product was characteri...

Embodiment 2

[0047] (1) Weigh 3.193 g of copper nitrate trihydrate and completely dissolve it in 15 mL of absolute ethanol under ultrasonic oscillation;

[0048] (2) Slowly add 5 mL of 1,2-propylene oxide to the above suspension, 4 min later, add 0.3355 g of nano-aluminum powder under the action of ultrasonic oscillation, and then add 1.03 g of nano-bismuth trioxide (30-80nm ), under the condition of constant temperature of 52 ℃, continue ultrasonic oscillation for 1 h to form a wet gel, then cool down and stand still;

[0049] (3) Dry the wet gel after static aging in a vacuum drying oven at 80 °C for 28 h to obtain a dry gel, and then calcinate the ground xerogel in a muffle furnace at 445 °C for 2.5 h, namely Double oxide composite super thermite Al / 1.5CuO·1.5Bi can be prepared 2 o 3 .

[0050] The inventor added 1-4 parts of Al powder, 1-8 parts of CuO, Bi 2 o 3 Composite super thermites with different compositions were prepared by changing the formula within the range of 1-8 part...

Embodiment 3

[0056] (1) Weigh 2.128 g of copper nitrate trihydrate and completely dissolve it in 15 mL of absolute ethanol under ultrasonic oscillation;

[0057] (2) Slowly add 5 mL of epichlorohydrin to the above suspension, and after 4 min, add 0.4599 g of nano-aluminum powder under the action of ultrasonic oscillation, and then add 0.70 g of nano-tin dioxide (30-80nm). Continue ultrasonic oscillation for 1 h at a constant temperature of ℃ to form a wet gel, then cool and stand still;

[0058] (3) The wet gel after static aging was dried in a vacuum drying oven at 80 °C for 24 h to obtain a dry gel, and then the ground xerogel was calcined in a muffle furnace at 439 °C for 2.5 h, namely Double oxide composite super thermite Al / CuO·SnO can be prepared 2 .

[0059] The inventor added 1-4 parts of Al powder, 1-8 parts of CuO, SnO 2 By changing the formula within the range of 1-8 parts, composite super thermites with different compositions can be prepared.

[0060] The product was charac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com