Device and method for continuously preparing high-purity single/double-wall carbon nano tubes

A double-walled carbon nanotube, high-purity technology, applied in the direction of carbon nanotubes, nanocarbon, nanotechnology, etc., can solve the problems of time-consuming purification, difficult operation, and small product output, so as to achieve easy installation and support, and avoid environmental pollution , the effect of saving the amount of acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

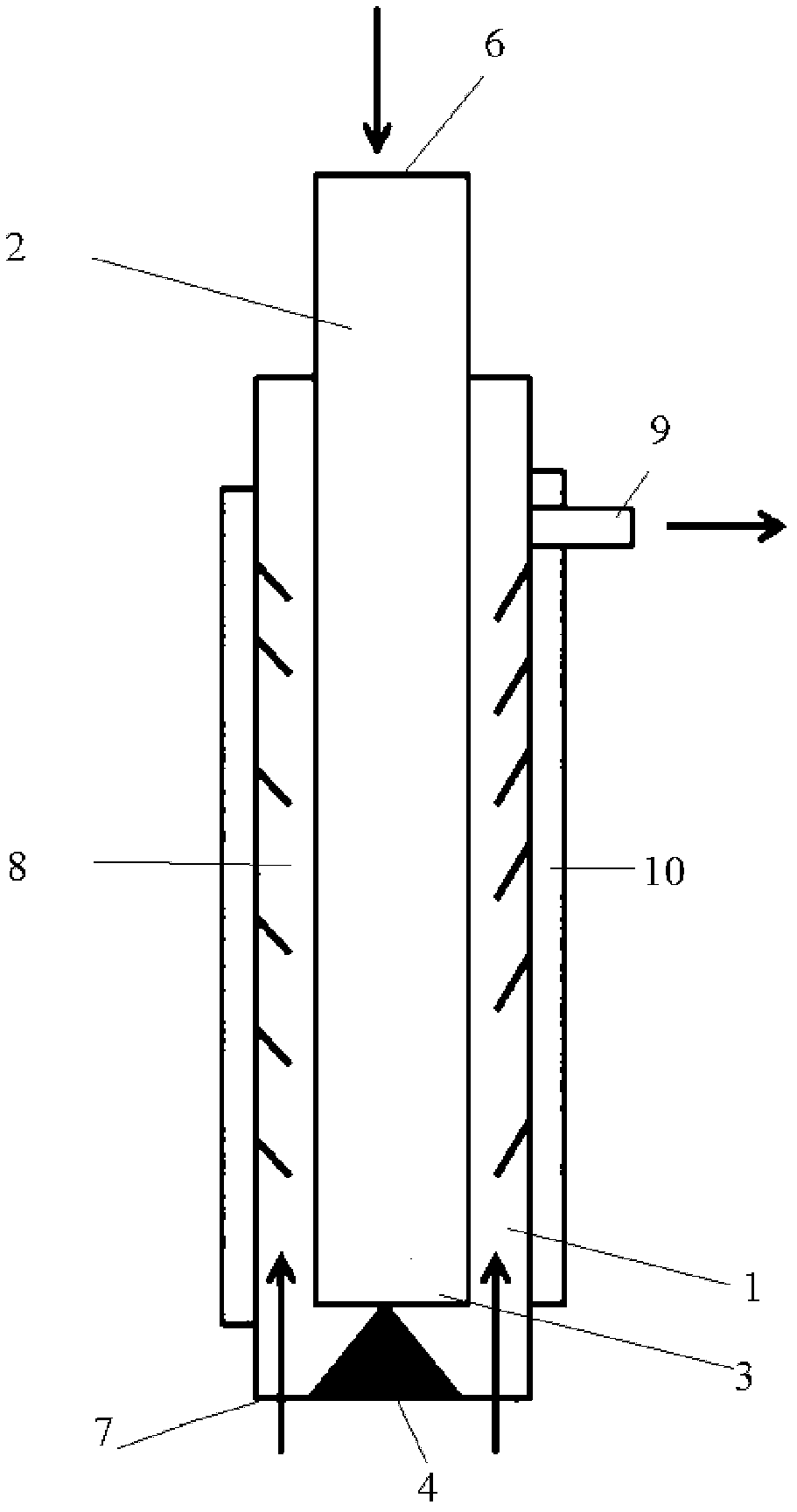

[0025] use as figure 1 In the reaction system shown, the descending bed 1 is inserted into the riser 2; the descending bed 1 has a gas-solid inlet 6 and a gas-solid outlet 3; the riser 2 has a gas inlet 7, a component area 8, and a gas-solid outlet 9. A heating system 10 and a conical structure 4; the gas-solid outlet 3 of the descending bed 1 is adjacent to the lower end of the conical structure 4 in the riser 2; the nozzle structure of the gas-solid outlet 3 is a fully open structure, and the lifting The gas inlet 7 of the pipe 2 is a plurality of symmetrical nozzles along the lower end of the riser 2 except the area occupied by the tapered structure 4, and the gas-solid outlet 9 of the riser 2 is arranged on the top of the riser 2; The ratio of the area to the cross-sectional area of the riser 2 is 10:1.

[0026] Catalyst uses Fe / MgO catalyst (Fe mass percent is 2%, all the other are MgO, particle diameter is 20 microns, bulk density is 1800kg / m 3 , the specific surface...

Embodiment 2

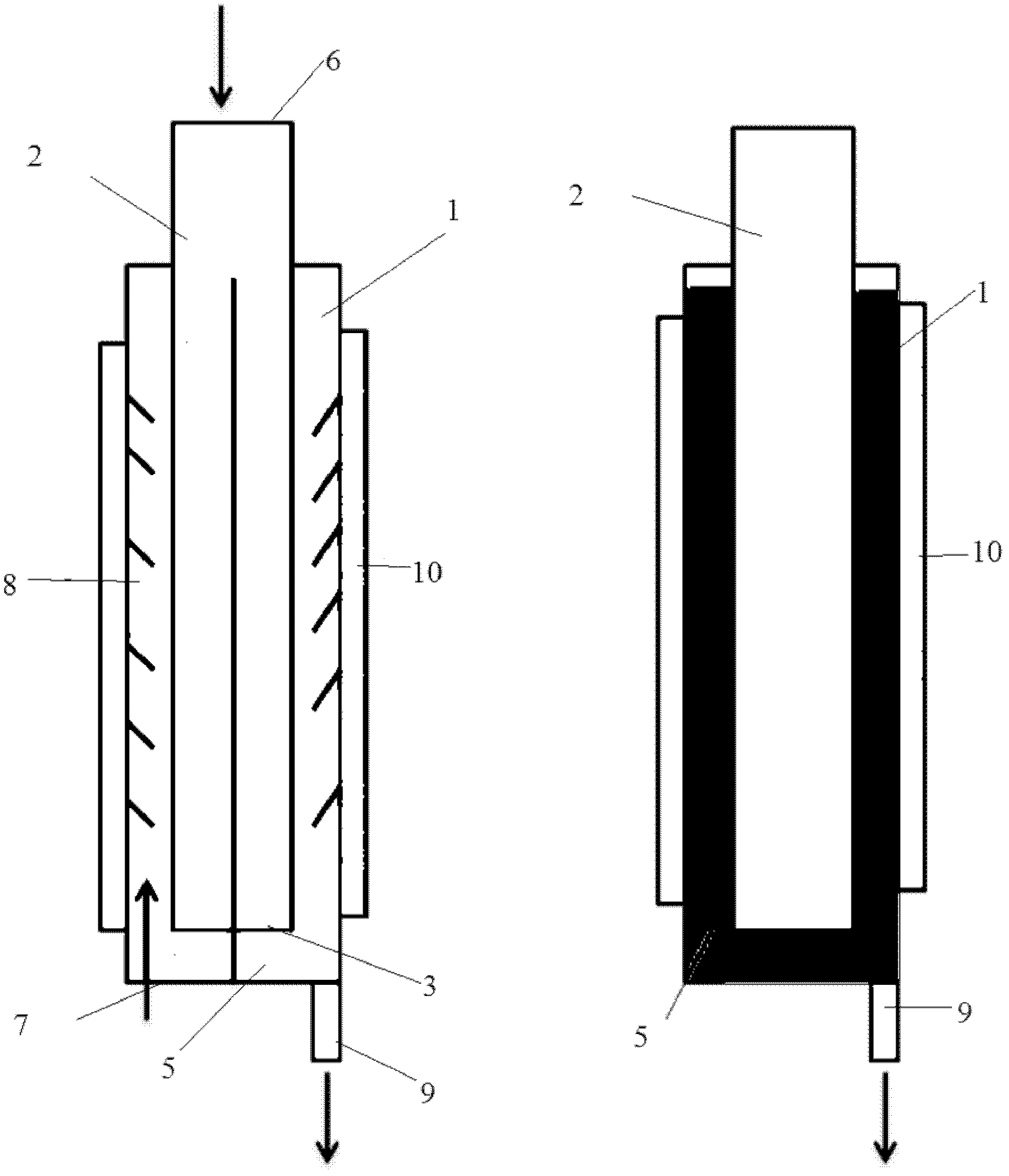

[0034] use as figure 2In the reaction system shown, the descending bed 1 is inserted into the riser 2; the descending bed 1 has a gas-solid inlet 6 and a gas-solid outlet 3; the riser 2 has a gas inlet 7, a component area 8, and a gas-solid outlet 9, a heating system 10, a partition 5; the gas-solid outlet 3 of the downer bed 1 is adjacent to the lower end of the partition 5 in the riser 2, and the partition 5 divides the riser 2 into two isolated bottom and middle parts. The two isolated areas communicate at the top of the riser 2, the bottom of one side of the partition 5 is provided with a gas inlet 7, the lower part of the downer bed 1 is an open structure on the same side, and a gas-solid outlet 3 is provided, and the other side of the partition 5 The bottom of the side is a closed structure, and a gas-solid outlet 9 is provided. The ratio of the cross-sectional area of the downer bed 1 to the cross-sectional area of the riser 2 is 1:1.

[0035] The catalyst uses Ni...

Embodiment 3

[0043] use as figure 1 In the reaction system shown, the descending bed 1 is inserted into the riser 2; the descending bed 1 has a gas-solid inlet 6 and a gas-solid outlet 3; the riser 2 has a gas inlet 7, a component area 8, and a gas-solid outlet 9. A heating system 10 and a conical structure 4; the gas-solid outlet 3 of the descending bed 1 is adjacent to the lower end of the conical structure 4 in the riser 2; the nozzle structure of the gas-solid outlet 3 is a fully open structure, and the lifting The gas inlet 7 of the pipe 2 is a plurality of symmetrical nozzles along the lower end of the riser 2 except the area occupied by the tapered structure 4, and the gas-solid outlet 9 of the riser 2 is arranged on the top of the riser 2; The ratio of the area to the cross-sectional area of the riser 2 is 4:1.

[0044] Catalyst using Fe / Mo / Al 2 o 3 Catalyst (the mass proportion of Fe is 1%, the mass proportion of Mo is 1%, and the rest are Al 2 o 3 , the particle size is 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com