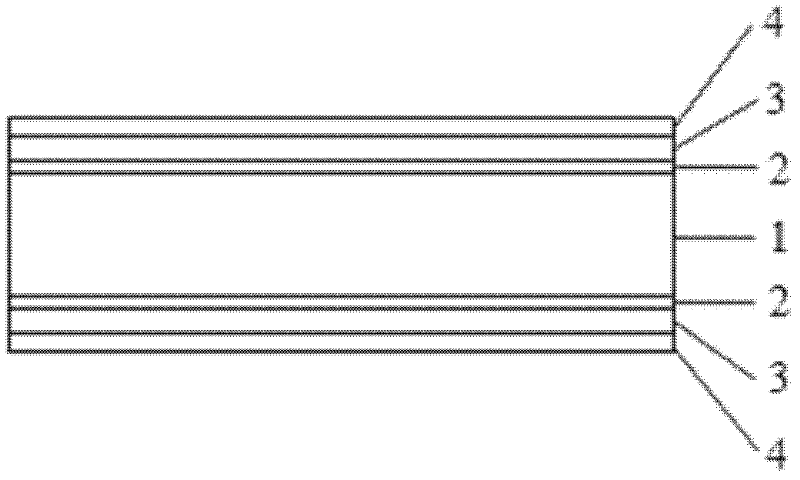

Solar battery packaging glass plated with three layers of anti-reflection films and preparation method thereof

A technology for solar cells and encapsulation glass, which is applied in the field of solar cell encapsulation glass coated with three-layer antireflection film and its preparation field, can solve the problems of inability to cover the visible light region, the limitation of solar energy utilization rate, etc., and achieves good chemical stability and good optical properties. performance, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Combine absolute ethanol, deionized water, concentrated hydrochloric acid and ethyl orthosilicate (high purity) in a molar ratio of 119.70:13.03:1.35×10 -2 : 1 was sequentially added into the reaction vessel, and then taken out after a constant temperature reaction at 30°C for 2 hours, placed in a closed glass container, and aged in a 30°C constant temperature bath for 7 days for later use. The resulting SiO 2 SiO in sol 2 The mass concentration is 1%.

[0027] Add anhydrous ethanol, deionized water, concentrated hydrochloric acid and butyl titanate to the reaction vessel in sequence at a molar ratio of 161.01:11.49:0.71:1 and 49.75:3.55:0.22:1, and react at a constant temperature at 30°C for 2 hours for later use . The resulting TiO 2 TiO in sol 2 The mass concentration is 1% and 3%.

[0028] 2) Partial SiO 2 with a mass concentration of 1% TiO 2 The sols were mixed in a mass ratio of 1:1 to obtain a composite sol, and the resulting composite sol was aged in...

Embodiment 2

[0033] 1) By the method described in Example 1, absolute ethanol, deionized water, concentrated nitric acid and ethyl tetrasilicate (high purity) were mixed in molar ratio 36.83: 4.01: 4.16×10 -3 : 1 was added to the reaction vessel to make SiO with a mass concentration of 3%. 2 Sol.

[0034] With the method described in Example 1, molar ratios of absolute ethanol, deionized water, concentrated nitric acid and butyl titanate were 49.75: 3.55: 0.22: 1 and 20.87: 1.49: 9.23 × 10 -2 : 1 to prepare mass concentrations of 3% and 6% TiO respectively 2 Sol.

[0035] 2) Partial SiO 2 with a mass concentration of 3% TiO 2 The sols were mixed at a mass ratio of 1.4:1 to prepare a composite sol, which was aged in a constant temperature tank at 30° C. for 7 days, and filtered for later use.

[0036] 3) Dip the cleaned and dried packaging glass substrate into SiO 2 -TiO 2 In the composite sol, the outer surface of the packaging glass substrate is covered with a layer of smooth compo...

Embodiment 3

[0040] 1) With the method described in Example 1, dehydrated alcohol, deionized water, concentrated nitric acid and tetraethyl orthosilicate (high purity) are mixed in molar ratio 20.52: 2.23: 2.31 * 10 -3 : 1 is added to the reaction vessel to make SiO with a mass concentration of 5%. 2 Sol.

[0041] With the method described in Example 1, molar ratios of absolute ethanol, deionized water, concentrated nitric acid and butyl titanate were 26.47: 1.89: 0.12: 1 and 9.65: 0.69: 4.27 × 10 -2 : 1 to prepare TiO with a mass concentration of 5% and 10% respectively 2 Sol.

[0042] 2) Partial SiO 2 with a mass concentration of 5% TiO 2 The sols were mixed at a mass ratio of 1:1 to prepare a composite sol, which was aged in a constant temperature bath at 30° C. for 7 days, and filtered for later use.

[0043] 3) Dip the cleaned and dried packaging glass substrate into SiO 2 -TiO 2 In the composite sol, the outer surface of the packaging glass substrate is covered with a layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com