YSZ (Yttria Stabilized Zirconia)-based composite thermal barrier coating material and preparation method thereof

A thermal barrier coating and coating technology, applied in the field of thermal barrier coating material and its preparation, calcium silicate modified YSZ-based composite thermal barrier coating material and its preparation, can solve the problem of reducing the thermal cycle life of the coating , lower thermal expansion coefficient of the coating, accelerated oxidation of the bonding layer, etc., to achieve uniform distribution of pores and micro-cracks, lower thermal conductivity, and strong anti-sintering ability at high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] 172 grams of YSZ (is mixed with 8wt% Y 2 o 3 Stabilized zirconia ZrO 2 material) was added to 500 ml of absolute ethanol, stirred at 50°C for 20 min to form a suspension, and 18 g of water and 6.3 g of nitric acid were added to mix uniformly;

[0036] Then add 20.8 grams of tetraethyl orthosilicate (TEOS), and continue stirring at 50° C. for 30 minutes until the tetraethyl orthosilicate is completely hydrolyzed;

[0037] Add 47.2 g Ca(NO 3 ) 2 4H 2 O, stir for 5-10 hours to make the mixture uniform; then dry at 90°C for 3 hours to obtain the precursor;

[0038] The dried precursor was placed in an electric furnace for sintering: the temperature was raised to 1400°C at a heating rate of 5°C / min, and the temperature was kept for 2 hours to obtain a composite powder of calcium silicate-coated YSZ material with a core-shell structure, wherein The mass ratio of calcium silicate to YSZ material is 1:10.

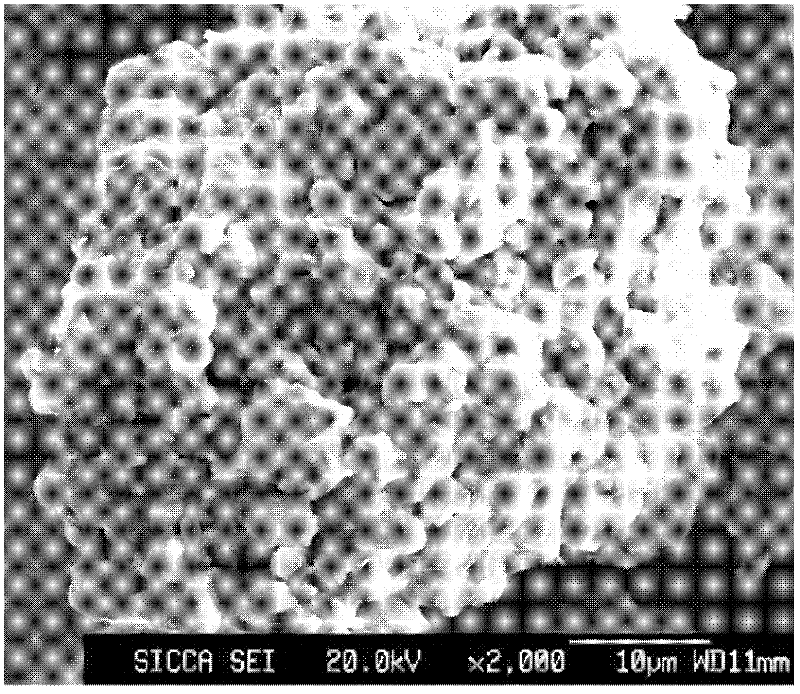

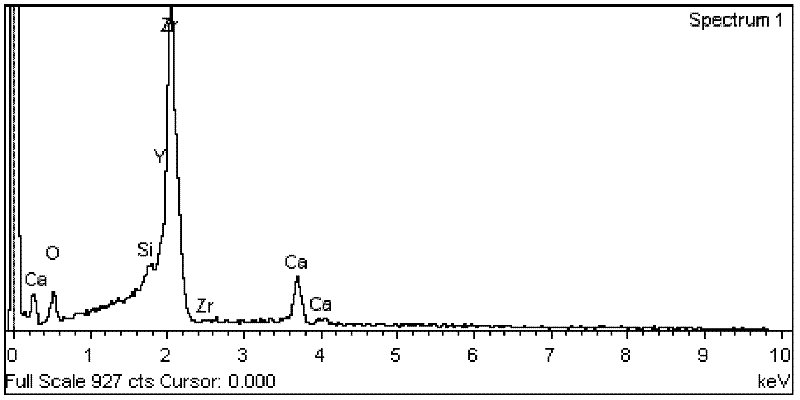

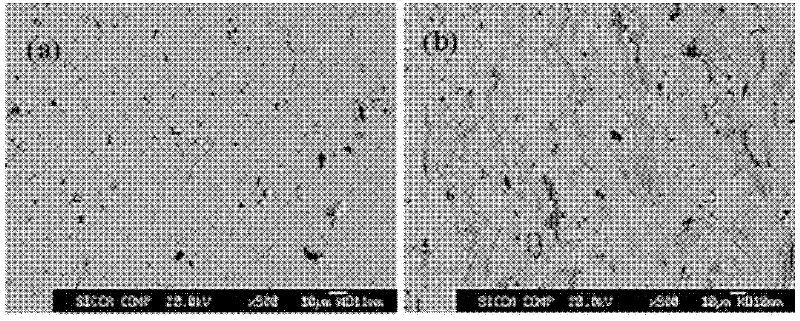

[0039] figure 1 The scanning electron micrograph of the composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com