Method and device for simultaneously recycling methylbenzene and dimethyl formamide in industrial waste gas by using solvent

A technology of dimethylformamide and industrial waste gas, which is applied in chemical instruments and methods, separation methods, separation/purification of carboxylic acid amides, etc., to achieve the effects of reducing energy consumption, improving recovery rate, and large economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Taking the treatment of 3000Kg / h industrial waste gas as an example to perform simulation calculation, the feed composition is as follows: air is 80%; DMF is 10%; toluene is 10%.

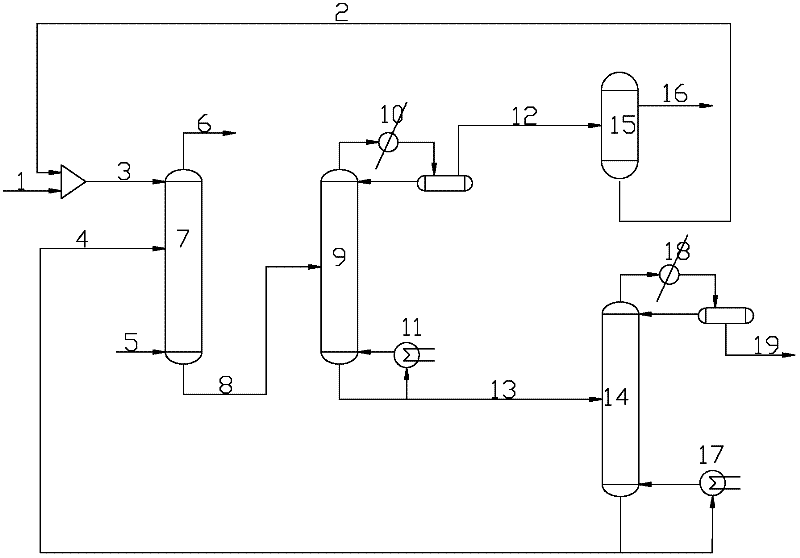

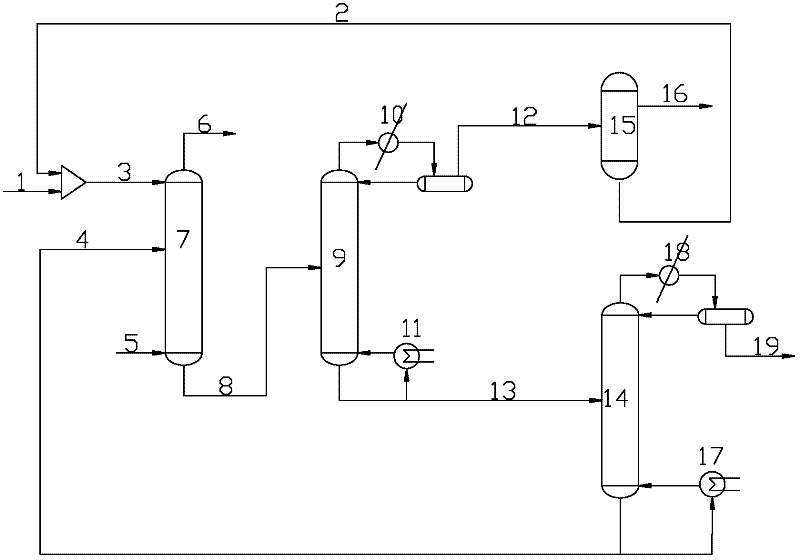

[0027] 2) if figure 1 As shown, the absorption tower 7 operates at a pressure of 100kPa, and the operating temperature in the tower is 33.5 to 38.1°C; industrial waste gas (5) enters the atmospheric pressure absorption tower (7) from the bottom of the tower, and the circulating solvent (4) flows from the upper part of the tower Enter the absorption tower (7), after circulating water mixes with supplemented fresh water (3) enter the absorption tower (7) from the tower top; Wherein, the mass ratio of water and solvent NMF is 1: 3, and absorbent total amount and feed The ratio of tower waste gas volume is 8: 1; After water (3) and solvent (4) absorb and purify contained DMF and toluene therein, the waste gas that reaches the emission standard is discharged from the top of the absorption tower...

Embodiment 2

[0032] Basic technology is with embodiment 1, and concrete operation parameter is as follows:

[0033] 1) Taking the treatment of 3000Kg / h industrial waste gas as an example to perform simulation calculation, the feed composition is as follows: air is 80%; DMF is 10%; toluene is 10%.

[0034] 2) if figure 1As shown, the absorption tower 7 operates at a pressure of 101.33kPa, and the operating temperature in the tower is 33.5 to 38.1°C; industrial waste gas (5) enters the atmospheric pressure absorption tower (7) from the bottom of the tower, and the circulating solvent (4) from the tower The upper part enters the absorption tower (7), and after the circulating water is mixed with the supplemented fresh water (3), it enters the absorption tower (7) from the top of the tower; wherein, the ratio of water and solvent NMF is 1: 4, and the total amount of absorbent and the incoming The ratio of tower waste gas volume is 5: 1; After water (3) and solvent (4) absorb and purify DMF an...

Embodiment 3

[0039] Basic technology is with embodiment 1, and concrete operation parameter is as follows:

[0040] 1) Taking the treatment of 3000Kg / h industrial waste gas as an example to perform simulation calculation, the feed composition is as follows: air is 80%; DMF is 10%; toluene is 10%.

[0041] 2) if figure 1 As shown, the absorption tower 7 operates at a pressure of 120kPa, and the operating temperature in the tower is 31.5 to 38.7°C; industrial waste gas (5) enters the atmospheric pressure absorption tower (7) from the bottom of the tower, and the circulating solvent (4) flows from the upper part of the tower Enter the absorption tower (7), after circulating water mixes with supplemented fresh water (3) enter the absorption tower (7) from the top of the tower; Wherein, the proportioning of water and solvent NMF is 1: 5, and the absorbent total amount and enter the tower The ratio of waste gas volume is 4:1; after water (3) and solvent (4) absorb and purify the DMF and toluene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com