Preparation method of styrene/N-phenylmaleimide binary copolymer

A maleimide binary copolymer and maleimide technology are applied in the field of preparing styrene/N-phenylmaleimide binary copolymer by coordination polymerization, which can solve the problem of affecting the copolymer. Quality, difficult to remove and other problems, to achieve the effect of less impurity content, easy temperature control, and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

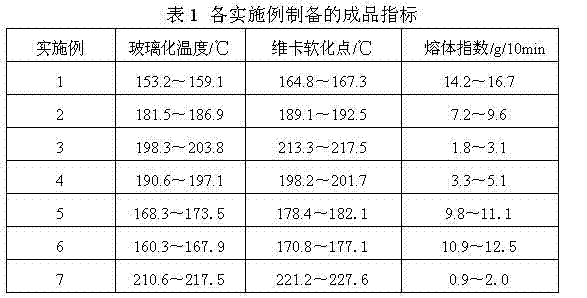

Embodiment 1

[0021] A method for preparing styrene / N-phenylmaleimide binary copolymer, operates according to the following steps:

[0022] Add 0.003mol La(P 507 ) 3 , 0.005mol triethylaluminum, 0.6mol N-phenylmaleimide, 1.2mol styrene and 1L toluene, reacted at 50°C for 5 hours, terminated the reaction with 1ml ethanol solution containing 5% hydrochloric acid, and reacted The mixture was poured into ethanol to precipitate the copolymer, and then filtered and dried to obtain the finished product.

[0023] The styrene / N-phenylmaleimide binary copolymer productive rate of present embodiment gained is 45%, and number average molecular weight is 3.5 * 10 4 , the molecular weight distribution is 7.2.

Embodiment 2

[0025] A method for preparing styrene / N-phenylmaleimide binary copolymer, operates according to the following steps:

[0026] Add 0.005mol La(P 204 ) 3 , 0.03mol trimethylaluminum, 0.7mol N-phenylmaleimide, 1.3mol styrene and 1L benzene, reacted at 45°C for 6 hours, terminated the reaction with 1ml ethanol solution containing 5% hydrochloric acid, and the reaction The mixture was poured into ethanol to precipitate the copolymer, and then filtered and dried to obtain the finished product.

[0027] The styrene / N-phenylmaleimide binary copolymer productive rate of present embodiment gained is 85%, and number average molecular weight is 25 * 10 4 , the molecular weight distribution is 4.8.

Embodiment 3

[0029] A method for preparing styrene / N-phenylmaleimide binary copolymer, operates according to the following steps:

[0030] Add 0.01mol Nd(P 507 ) 3 , 0.02mol trimethylaluminum, 0.03mol triethylaluminum, 0.6mol N-phenylmaleimide, 1.2mol styrene and 1L toluene, react at 50°C for 5 hours, and use 1ml of 5% hydrochloric acid The ethanol solution terminates the reaction, the reactant is poured into ethanol to precipitate the copolymer, and then filtered and dried to obtain the finished product.

[0031] The styrene / N-phenylmaleimide binary copolymer productive rate that the present embodiment gained is 96%, and number average molecular weight is 41 * 10 4 , the molecular weight distribution is 2.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com