Electrode surface modification material, preparation method thereof and application thereof

An enzyme electrode and general formula technology, applied in the field of electrode surface modification materials and its preparation and application, can solve the problems of affecting the electrochemical performance of the electrode, limited pH value range, increasing the preparation steps, etc., and achieve the effect of good redox conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

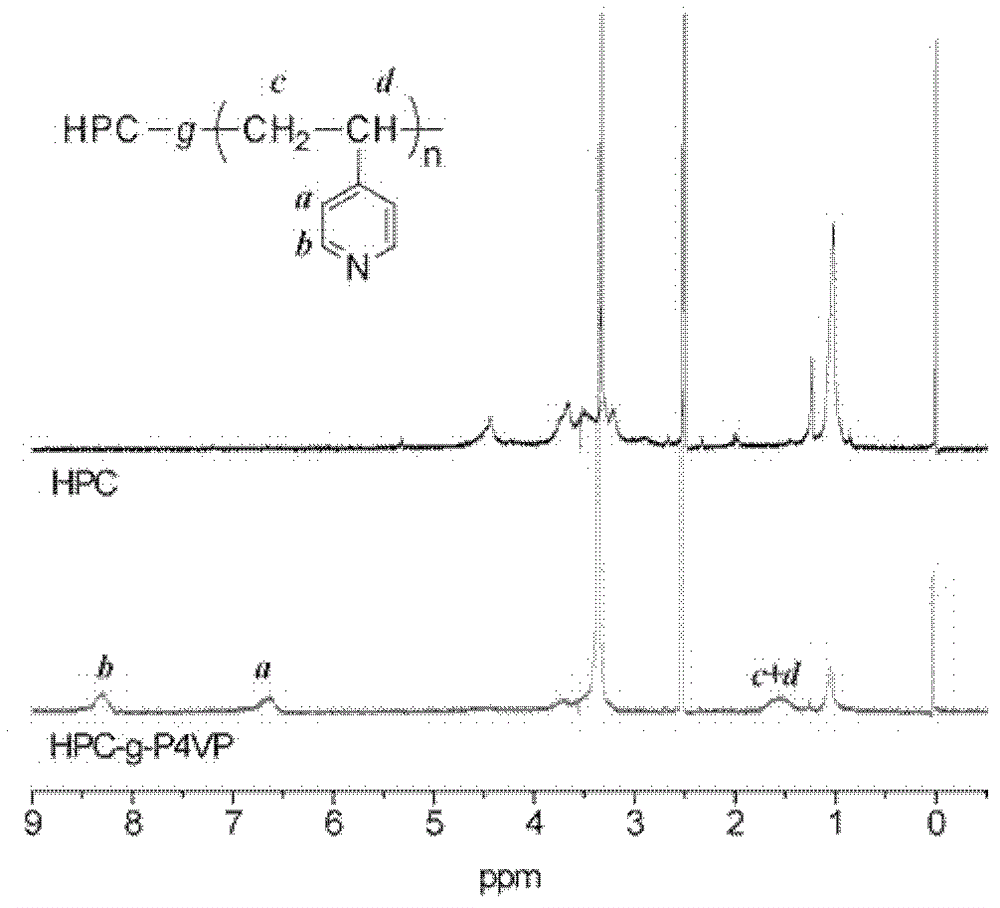

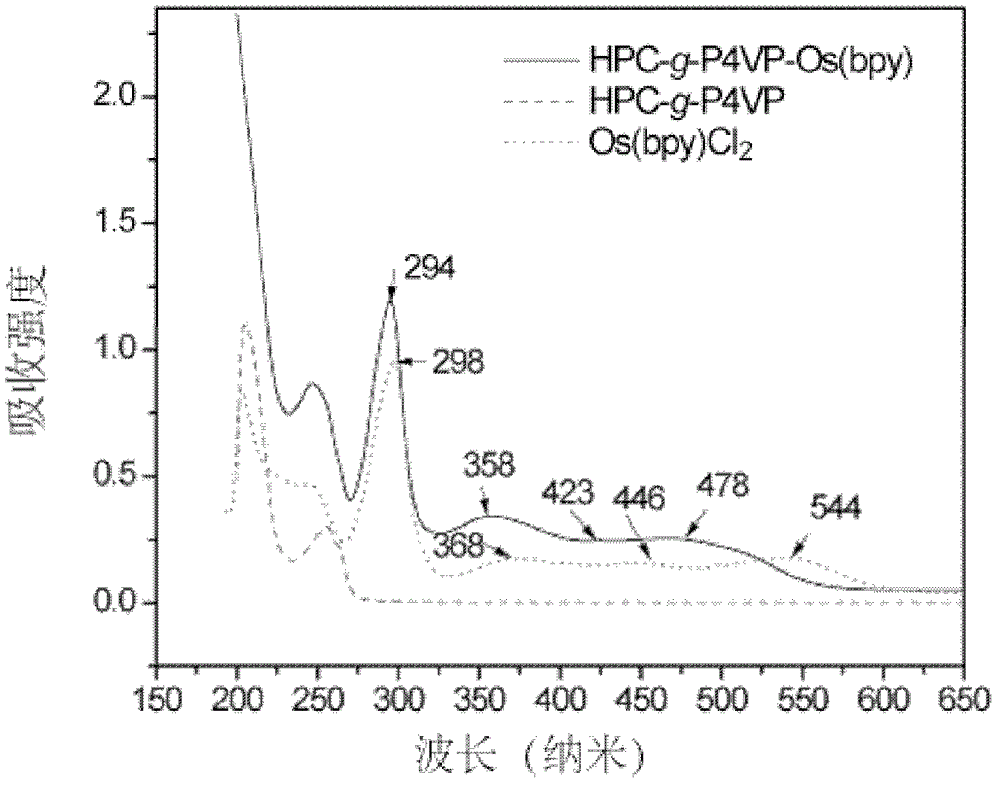

[0049] Embodiment 1, preparation cell-g-P4VP-Os

[0050] Weigh 0.1 g of hydroxypropyl cellulose with a weight average molecular weight of 80,000 and a degree of substitution of 3.5, add it to 50 mL of deionized water, blow nitrogen, and dissolve completely in a constant temperature oil bath at 40 degrees Celsius. Regulate the pH of the solution to 1.5 with concentrated nitric acid, add 2 milliliters of 4-vinylpyridine (1.96 g), stir to make it fully dissolve, then add 5 mL of initiator ceric ammonium nitrate aqueous solution (0.008 g / ml), continue nitrogen, and then Seal and react for 2 hours. The reaction was terminated with hydroquinone. The reaction mixture was precipitated, filtered, dialyzed, and dried to obtain a cellulose derivative grafted polyvinylpyridine copolymer with a weight average molecular weight of 900,000 (measured by gel permeation chromatography, and the mobile phase was N,N-dimethylformamide) .

[0051] Weigh 10 mg of cellulose derivative grafted polyv...

Embodiment 2

[0055] Embodiment 2, preparation cell-g-P4VP-Os

[0056] Weigh 0.1 g of hydroxypropyl cellulose with a weight average molecular weight of 80,000 and a degree of substitution of 3.5, add it to 50 mL of deionized water, blow nitrogen, and dissolve completely in a constant temperature oil bath at 40 degrees Celsius. Regulate the pH of the solution to 1.5 with concentrated nitric acid, add 0.5 milliliters of 4-vinylpyridine (0.49 g), stir to make it fully dissolve, then add 5 mL of initiator ceric ammonium nitrate aqueous solution (0.008 g / ml), continue nitrogen, and then React with seal for 6 hours. The reaction was terminated with hydroquinone. The reaction mixture is precipitated, filtered, dialyzed, and dried to obtain a cellulose derivative grafted polyvinylpyridine copolymer with a weight average molecular weight of 100,000 (measured by gel permeation chromatography, and the mobile phase is N,N-dimethylamide).

[0057] Weigh 10 mg of cellulose derivative-grafted polyvinylp...

Embodiment 3

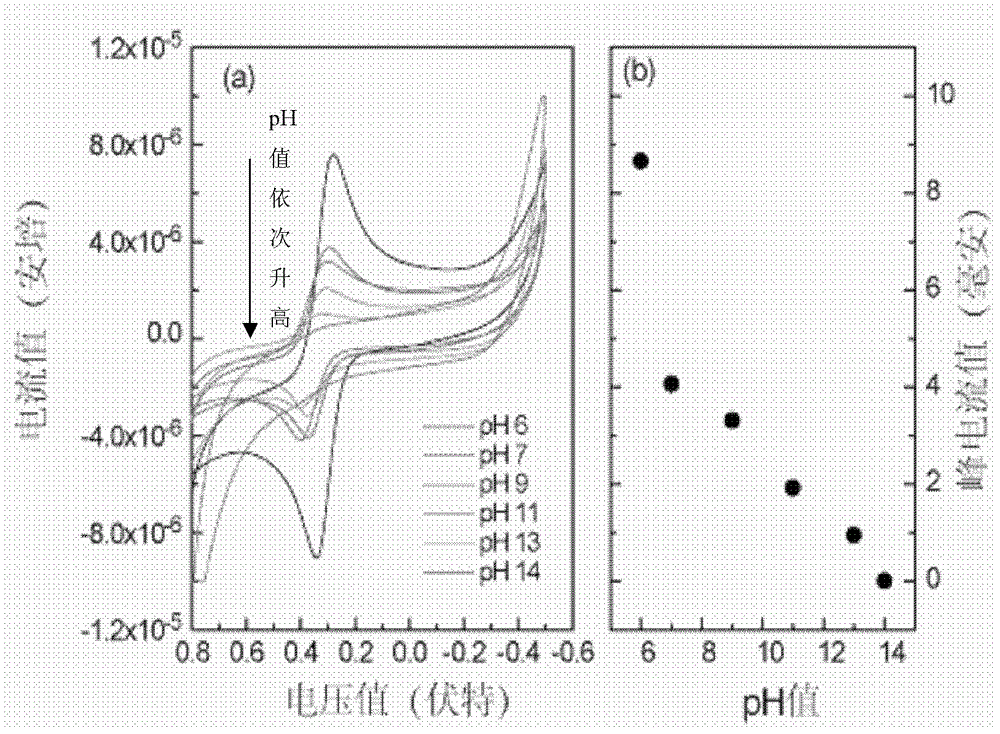

[0059] Embodiment 3, preparation of glucose oxidase electrode modified by cell-g-P4VP-Os

[0060] (1), 25 mg of cell-g-P4VP-Os prepared in Example 1 was fully dissolved in 5 ml of deionized water, and prepared into a solution with a concentration of 5 g / L;

[0061] (2), weigh 50 milligrams of glucose oxidase (enzyme activity > 100U / mg), fully dissolve in 5 milliliters of deionized water, prepare a solution with a concentration of 10 grams per liter, and refrigerate for later use;

[0062] (3) Appropriate amounts of the solutions of steps (1) and (2) were respectively taken to form a mixed solution at a volume ratio of 1:1, and fully mixed evenly. The mixed solution was drip-coated on the surface of the working electrode, and dried naturally to form a film to obtain a cell-g-P4VP-Os modified glucose oxidase electrode.

[0063] The above-mentioned glucose oxidase electrode was tested for electrical performance, and the results of cyclic voltammetry scanning were as follows: fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com