A kind of preparation method of nano cationic spherical polyelectrolyte brush

A polyelectrolyte brush and cation technology, which is applied in the field of preparation of nano-cationic spherical polyelectrolyte brushes, can solve the problems of easy formation of steric hindrance, difficulty in increasing the grafting density and the like, and achieve the effect of high grafting density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

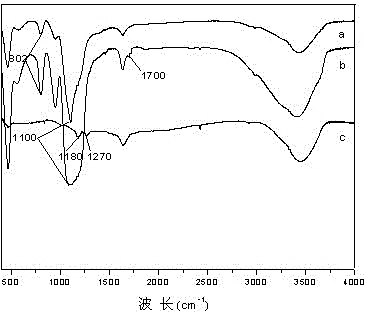

Image

Examples

Embodiment 1

[0029] Step 1, using the sol-gel method to prepare monodisperse nano-silica microspheres:

[0030] The preparation method of monodisperse nano-silica microspheres refers to the literature: Kota Sreenivasa Rao, et al. Journal of Colloid and Interface Science 2005; 289:125-131, and the obtained mass fraction is 4% nano-silica isopropanol Suspension, wherein the average particle size of silica microspheres is 100nm.

[0031] Step 2, preparing silica microspheres with unsaturated double bonds on the surface:

[0032] Add 40mg of γ-methacryloxypropyltrimethoxysilane (KH-570) to 100ml of alcohol-water mixture to obtain a reaction system. The volume ratio of alcohol and water in the alcohol-water mixture is 10:1, and the Adjust the pH of the reaction system to 4, and hydrolyze the obtained reaction system at room temperature for 1 hour; add 20 g of the nano-silica isopropanol suspension obtained in step 1 to the hydrolyzed reaction system, and reflux under the condition of a 70°C wa...

Embodiment 2

[0037] Step 1, using the sol-gel method to prepare monodisperse nano-silica microspheres:

[0038]The preparation method of monodisperse nano-silica microspheres refers to the literature: Kota Sreenivasa Rao, et al. Journal of Colloid and Interface Science 2005; 289:125-131, and the obtained mass fraction is 4% nano-silica isopropanol Suspension, wherein the average particle size of silica microspheres is 50nm.

[0039] Step 2, preparing silica microspheres with unsaturated double bonds on the surface:

[0040] Add 40mg of γ-methacryloxypropyltrimethoxysilane (KH-570) to 100ml of alcohol-water mixture to obtain a reaction system. The volume ratio of alcohol and water in the alcohol-water mixture is 3:1, and the Adjust the pH of the reaction system to 3, and hydrolyze the obtained reaction system at room temperature for 1 hour; add 20 g of the nano-silica isopropanol suspension obtained in step 1 to the hydrolyzed reaction system, and reflux under the condition of a water bath...

Embodiment 3

[0045] Step 1, using the sol-gel method to prepare monodisperse nano-silica microspheres:

[0046] The preparation method of monodisperse nano-silica microspheres refers to the literature: Kota Sreenivasa Rao, et al. Journal of Colloid and Interface Science 2005; 289:125-131, and the obtained mass fraction is 4% nano-silica isopropanol Suspension, wherein the average particle size of silica microspheres is 90nm.

[0047] Step 2, preparing silica microspheres with unsaturated double bonds on the surface:

[0048] Add 24mg of γ-methacryloxypropyltrimethoxysilane (KH-570) to 100ml of alcohol-water mixture to obtain a reaction system. The volume ratio of alcohol and water in the alcohol-water mixture is 10:1, and the Adjust the pH of the reaction system to 4, and hydrolyze the obtained reaction system at room temperature for 1 hour; add 20 g of the nano-silica isopropanol suspension obtained in step 1 to the hydrolyzed reaction system, and reflux under the condition of a 70°C wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com