Preparation method for low-density viscoelastic polyurethane foam

A technology of polyurethane foam and viscoelasticity is applied in the field of preparation of viscoelastic polyurethane foam, which can solve the problems of human and environmental hazards, health threats to operators, etc., and achieve the effects of low foam odor, lower foam density, and adjustment of rebound time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

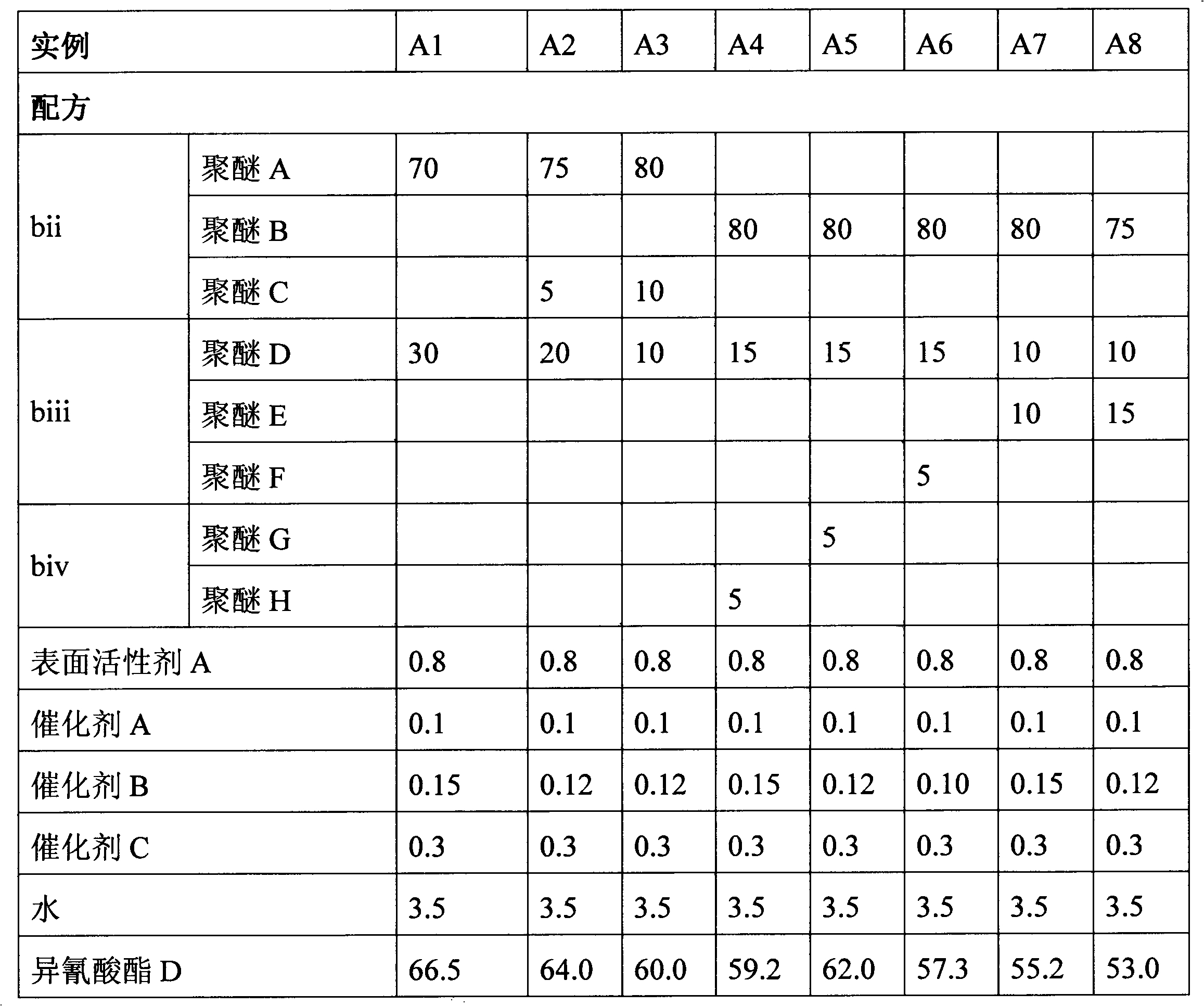

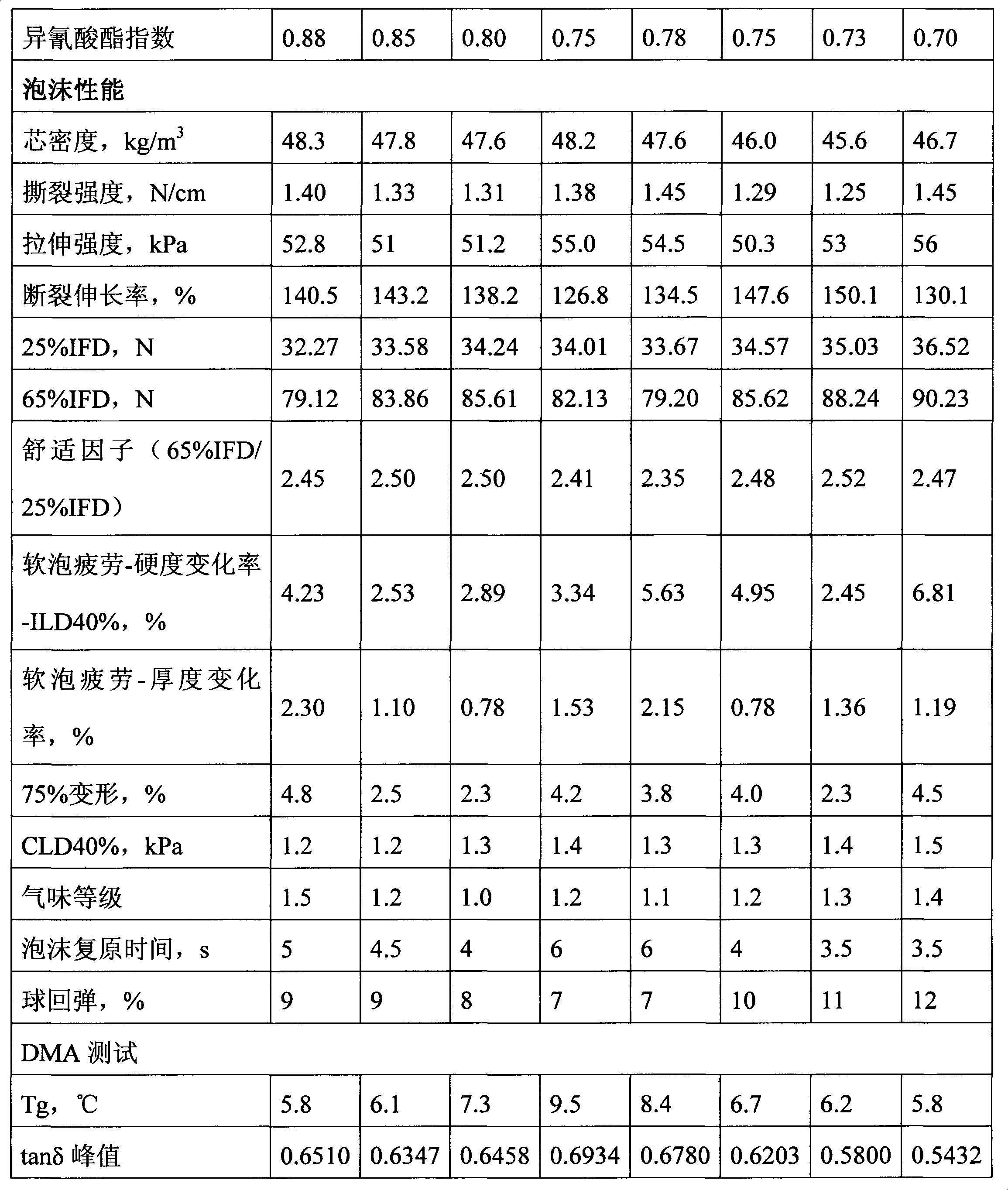

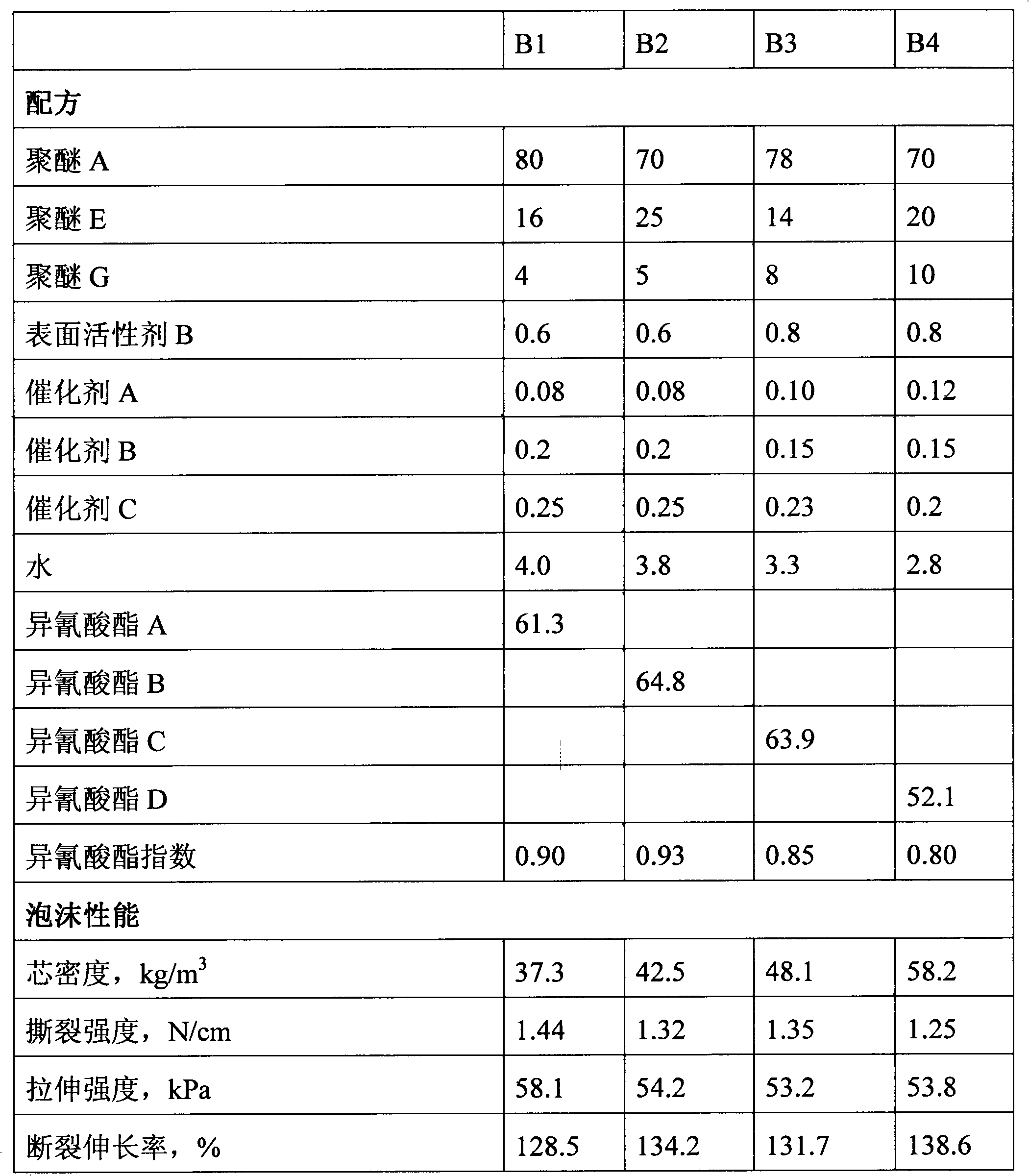

[0054] A viscoelastic polyurethane foam is formed according to the present invention, and the components forming the composition are expressed in parts by weight. The isocyanate index refers to the ratio of the isocyanate group NCO to its active hydrogen equivalents.

[0055] The raw material characteristics involved in the embodiments of the present invention are described as follows:

[0056] Isocyanate-reactive components (bii)

[0057] Polyether A: Glycerin as the initiator, functionality 3, 75% EO-25% PO copolymerization, hydroxyl value 34mgKOH / g, weight average molecular weight 4950

[0058] Polyether B: Glycerin as the initiator, functionality 3, 80% EO-20% PO copolymerization, hydroxyl value 51mgKOH / g, weight average molecular weight 3300

[0059] Polyether C: Glycerin as the initiator, functionality 3, 85% EO-15% PO copolymerization, hydroxyl value 168mgKOH / g, weight average molecular weight 1000

[0060] Isocyanate reactive component (biii)

[0061] Polyether D: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com