Amino molding plastic capable of solidifying quickly and being stored for long time

An amino molding compound, fast-curing technology, applied in the field of fast-curing long-storage amino molding compound, to achieve stable storage performance, enhance the activity of the curing agent, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

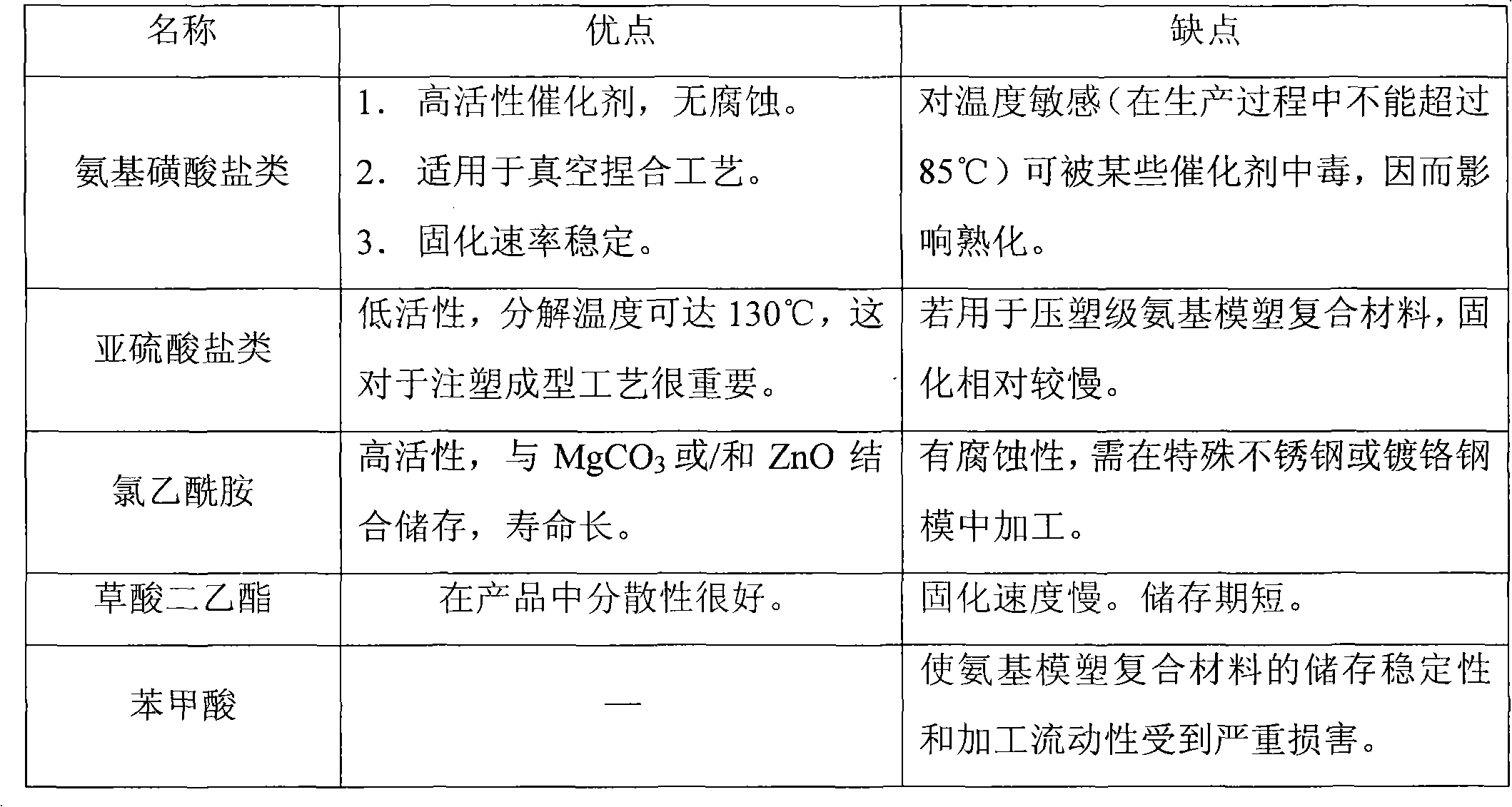

Method used

Image

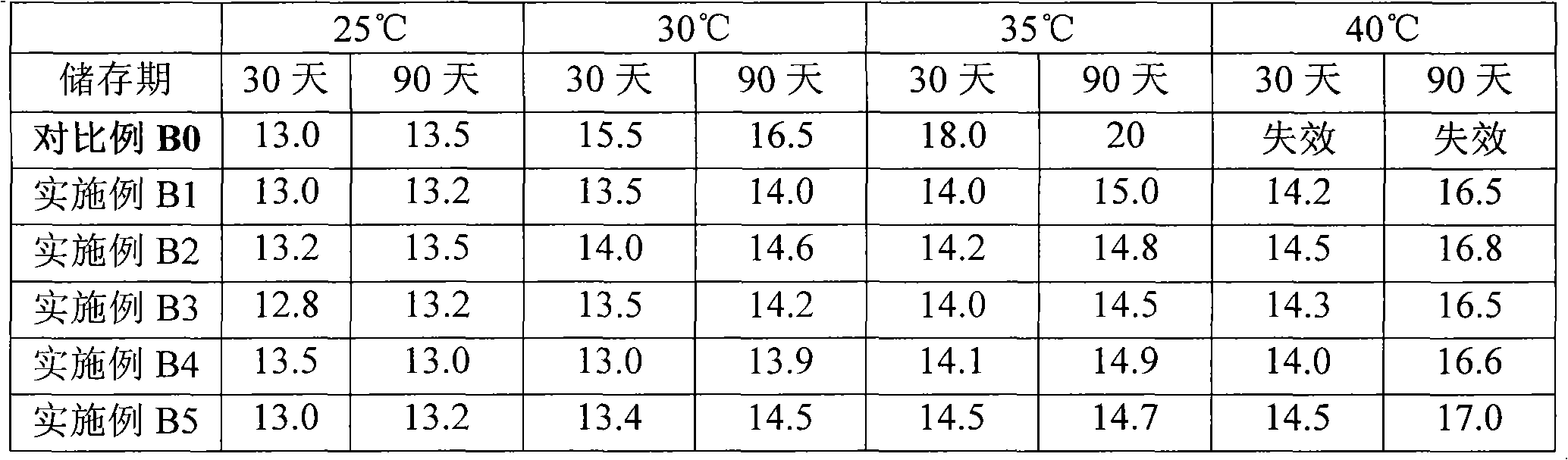

Examples

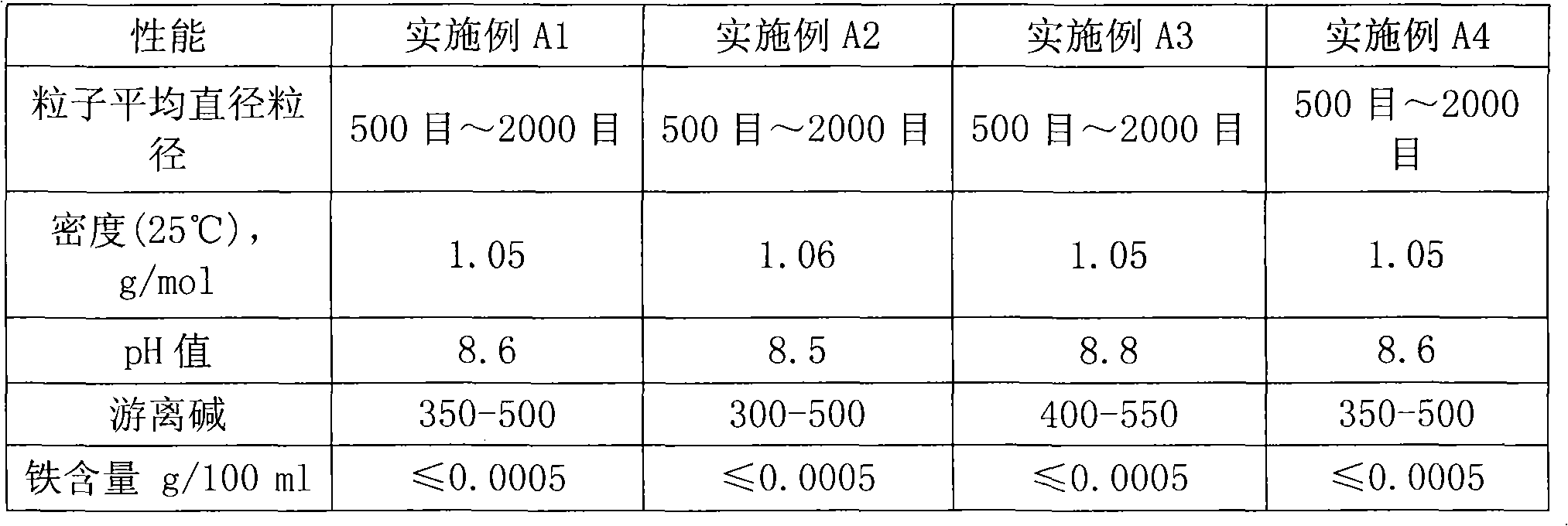

Embodiment A1

[0038] (1) Add 45 parts of water into the reaction kettle, then add 21 parts of triethanolamine, heat to 35°C, adjust the pH to 8.5-PH 9.0 with ammonia water, and obtain an alkaline triethanolamine aqueous solution;

[0039] (2) Keep the temperature in the reaction kettle at 35° C., add 22 parts of ammonium sulfamate in the aqueous solution of triethanolamine and dissolve it, so as to obtain an ammonium triethanolamine disulfonate solution;

[0040] (3) In the above triethanolamine disulfonate ammonium solution, add 5 parts of zinc oxide / magnesium hydroxide = 1 / 1 inorganic nanoparticle mixture, control the temperature at 40°C, and react for 30 minutes, then cool it through the water in the reactor jacket to room temperature to prepare a latent curing agent for absorbing inorganic nanoparticles with sulfamic acid, that is, a latent curing agent for sulfamic acid-containing inorganic nanoparticles.

Embodiment A2

[0042] (1) Add 43 parts of water into the reaction kettle, then add 20 parts of triethanolamine, heat to 35°C, adjust the pH to 8.5-PH 9.0 with ammonia water, and obtain an alkaline triethanolamine aqueous solution;

[0043] (2) Keep the temperature in the reaction kettle at 35° C., add 22 parts of calcium iminodisulfonate to the aqueous solution of triethanolamine and dissolve it to obtain an ammonium triethanolamine disulfonate solution;

[0044] (3) In the above triethanolamine disulfonate ammonium solution, add 5 parts of zinc oxide / magnesium hydroxide = 1 / 1 inorganic nanoparticle mixture, control the temperature at 40°C, and react for 30 minutes, then cool it through the water in the reactor jacket to room temperature to prepare a latent curing agent for absorbing inorganic nanoparticles with sulfamic acid, that is, a latent curing agent for sulfamic acid-containing inorganic nanoparticles.

Embodiment A3

[0046] (1) Add 48 parts of water into the reaction kettle, then add 23 parts of triethanolamine, heat to 35°C, adjust the pH to 8.5-PH 9.0 with ammonia water, and obtain an alkaline triethanolamine aqueous solution;

[0047] (2) Keep the temperature in the reaction kettle at 35° C., add 22 parts of sodium sulfamate in the triethanolamine aqueous solution and dissolve it to obtain a solution of ammonium triethanolamine disulfonate;

[0048] (3) In the above triethanolamine disulfonate ammonium solution, add 6 parts of zinc oxide / magnesium hydroxide = 1 / 1 inorganic nanoparticle mixture, control the temperature at 40°C, and react for 30 minutes, then cool it through the water in the reactor jacket to room temperature to prepare a latent curing agent for absorbing inorganic nanoparticles with sulfamic acid, that is, a latent curing agent for sulfamic acid-containing inorganic nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com